Screw cap screwing machine control system and method thereof

A control system and tightening machine technology, applied in the direction of electrical program control, program control in sequence/logic controller, manufacturing tools, etc., can solve problems such as difficult operation, bulky equipment, complicated control process, etc., and achieve enhanced humanization , Enhance convenience, enhance the effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

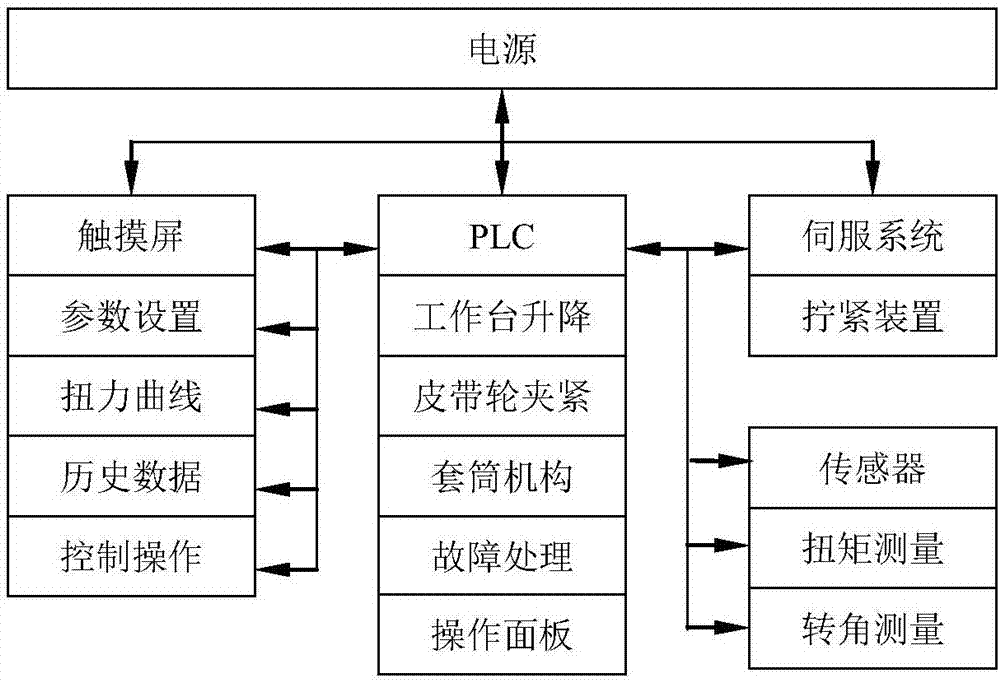

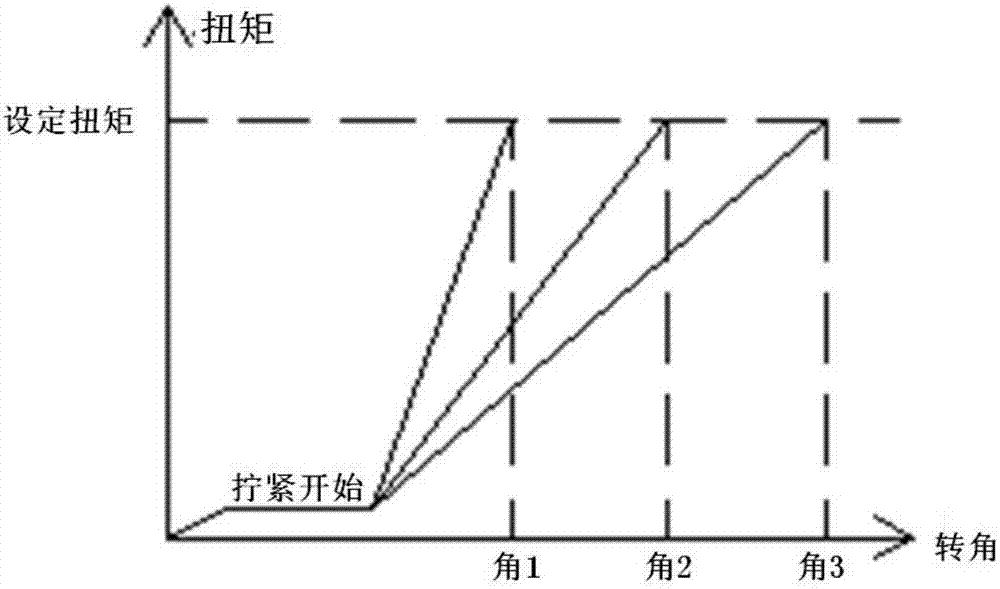

[0023] like figure 1 As shown, a nut tightening machine control system includes a power supply and a touch screen, PLC and servo system respectively connected to the power supply. Control operation module, PLC is equipped with fault processing module and human-computer interaction module, PLC control is connected with worktable lifting mechanism, pulley tightening mechanism, sleeve mechanism, servo system is connected with tightening device, and PLC and servo system are connected with torque sensor. The PLC is also equipped with an alarm module, which is connected to the servo system through the fault processing module, and detects whether the clamping is in place through the PLC. If there is no clamping within the specified time, it will alarm. The human-computer interaction module is equipped with an emergency stop button. The emergency stop button controls the workbench lifting mechanism, pulley tightening mechanism, sleeve mechanism and tightening device through the PLC. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com