Fault risk assessment method of heavy-type roller loading intelligent robot

A technology of intelligent robots and failure risks, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as increasing maintenance costs, achieve the effect of reducing costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The patent of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

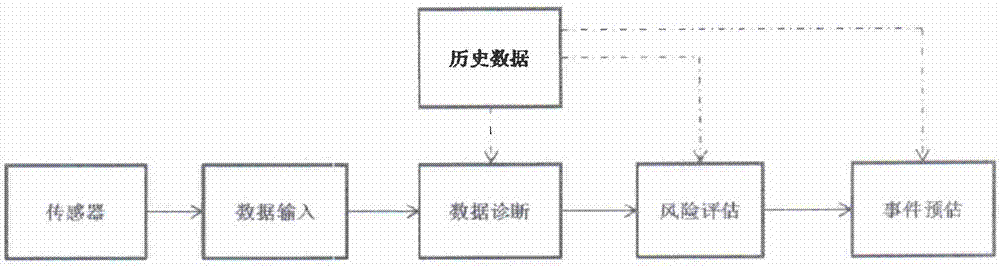

[0028] Such as figure 1 As shown, the present invention provides a fault risk assessment method loaded with intelligent robots, which mainly includes three modules of fault diagnosis, risk assessment and accident prediction, as well as historical data. Analyze the real-time data of the equipment sensors on the intelligent robot, calculate the parameters to measure the dynamic trend of the data, the data deviation and its rate of change, and diagnose whether there is any abnormality in the data, and then calculate the corresponding risk value caused by the potential failure according to the dynamic trend parameters of the data , and then divide the corresponding risk level. If the risk exceeds the safety level, an emergency stop signal is sent, and the type of accident caused by the potential failure is estimated, and the staff is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com