Non-polarity high voltage DC contactor arc extinguishing system structure

A high-voltage direct current, system structure technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of low life of on-load switching, large contactor size, waste of installation space, etc., and achieve good arc extinguishing effect and shrink Small size, saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

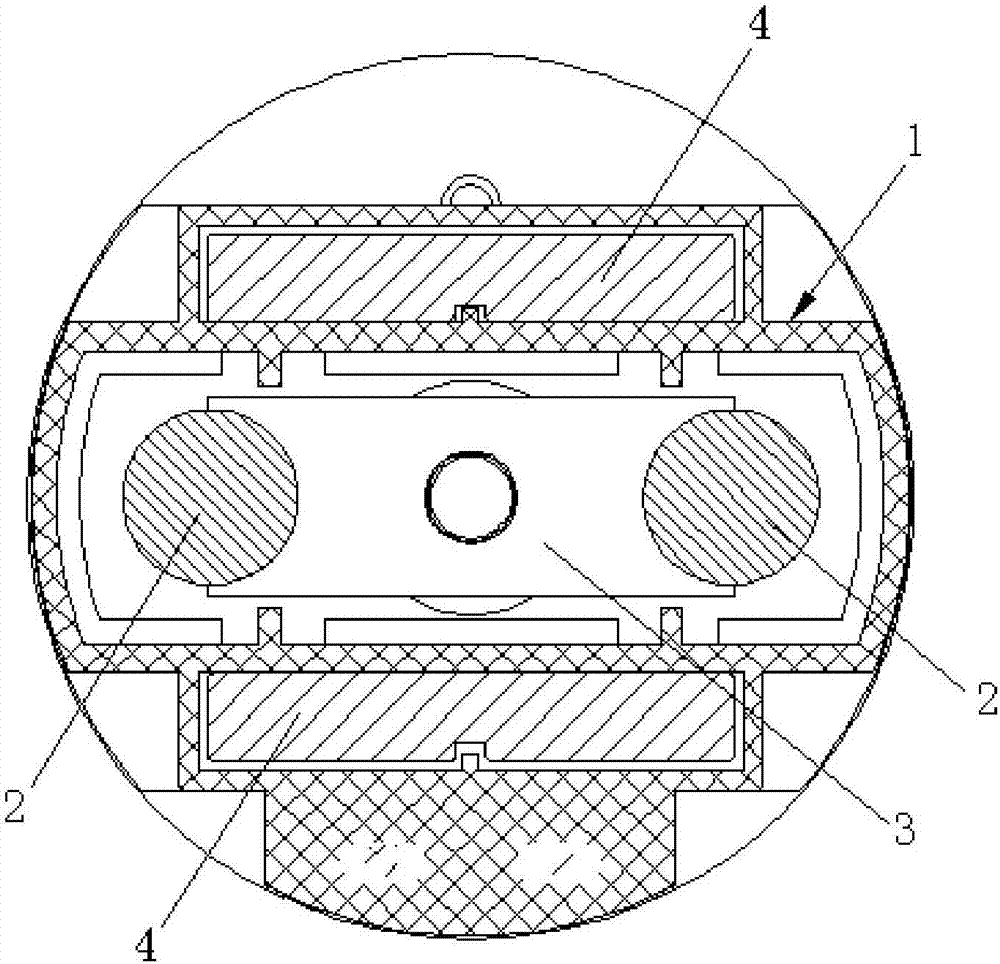

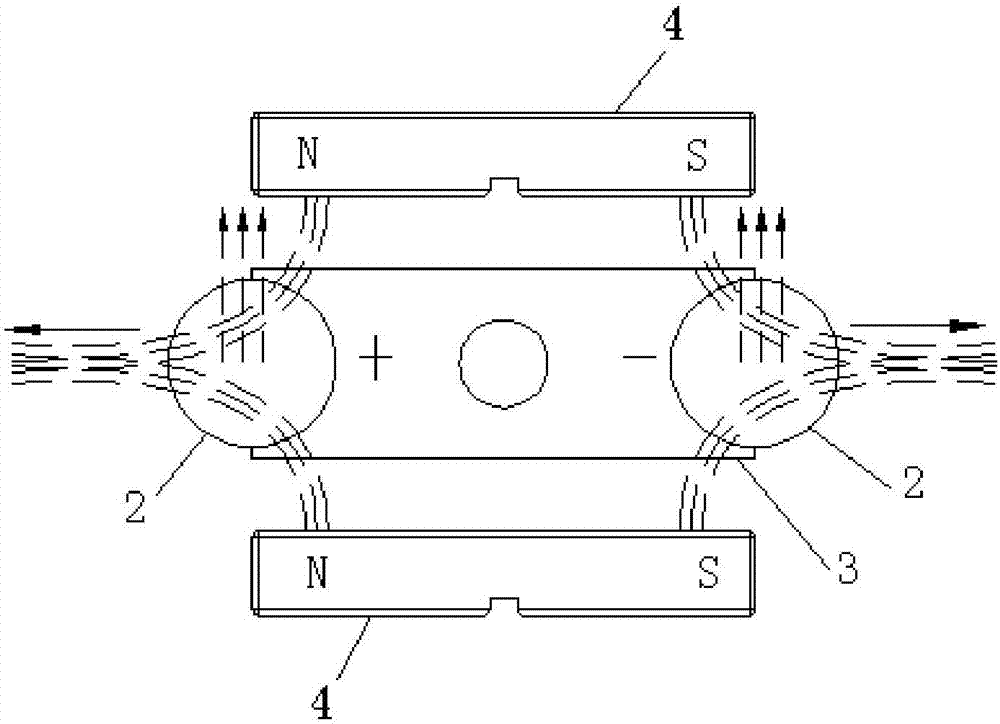

[0021] Please refer to the attached figure 1 As shown, it shows a schematic cross-sectional structure diagram of the first embodiment of the arc extinguishing system structure of the non-polar high-voltage DC contactor of the present invention. The arc extinguishing system structure of the non-polar high-voltage DC contactor includes an arc extinguishing chamber 1, two static contact points 2 arranged side by side on the top of the arc extinguishing chamber 1, and a movable built-in arc extinguishing chamber 1 The moving contact piece 3, the moving contact piece 3 and the two static contact points 2 are vertically opposite to each other, and the moving contact piece 3 can also communicate with the two static contact points 2, or the The moving contact piece 3 can also be disconnected from the two static contact points 2 respectively (it is common knowledge and does not belong to the focus of the present invention, so it will not be described in detail here); particularly, at t...

Embodiment 2

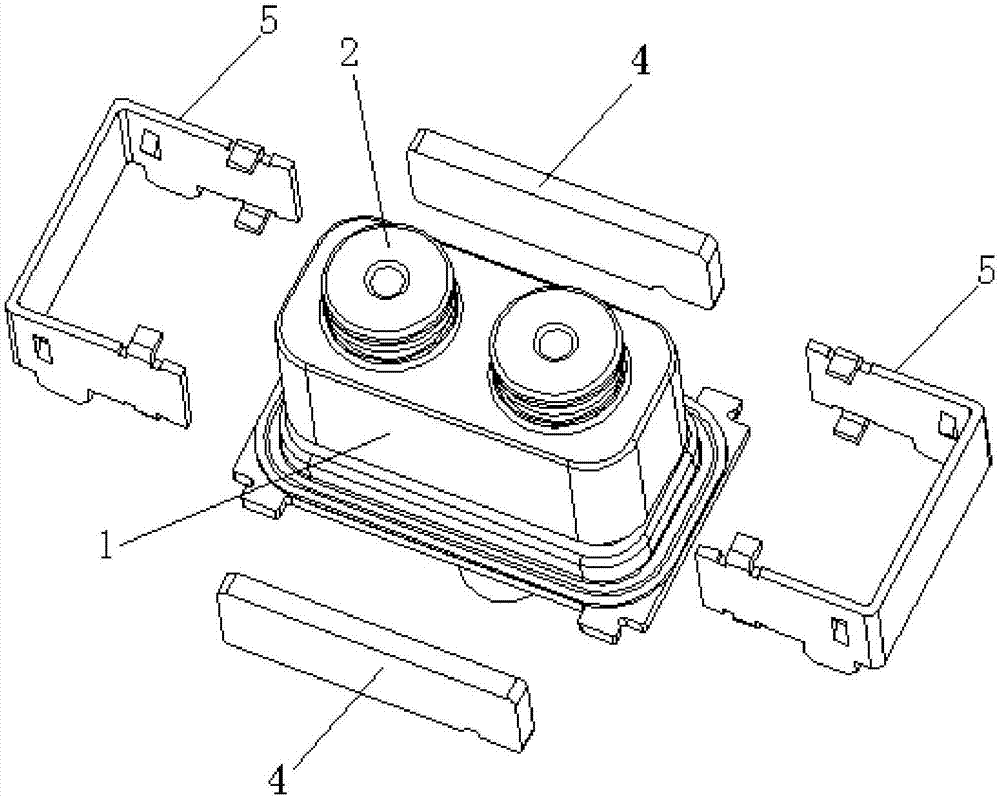

[0024] Please refer to the attached figure 2 , which shows a schematic diagram of the exploded structure of the second embodiment of the arc extinguishing system structure of the non-polar high-voltage DC contactor of the present invention. The structure of the non-polar high-voltage DC contactor arc extinguishing system shown in Embodiment 2 is generally similar to the structure of the non-polar high-voltage DC contactor arc extinguishing system shown in Embodiment 1. The main difference is that in Embodiment 1, the two The permanent magnets 4 are all built in the arc extinguishing chamber 1; and in embodiment 2, the two permanent magnets 4 are relatively arranged on the outer surface of the side wall of the arc extinguishing chamber 1 through two brackets 5 .

[0025] In addition, in embodiment 2, it is further preferred that the arc extinguishing chamber 1 is formed by sintering and sealing ceramics and metal; the upper end surface of each permanent magnet 4 is higher tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap