Cable gland and electrical device

A cable fixing head and tight head technology, applied in the direction of electrical components, etc., can solve the problems of unfavorable long-term use, poor cable fastening, waterproof, dustproof, acid and alkali resistance, etc., to improve waterproof and firm assembly , Improve the effect of antimagnetic and insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

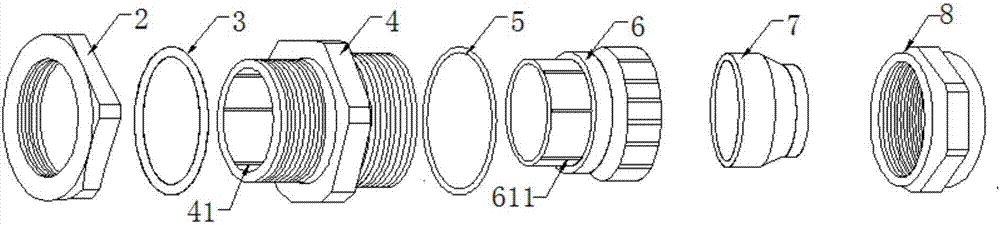

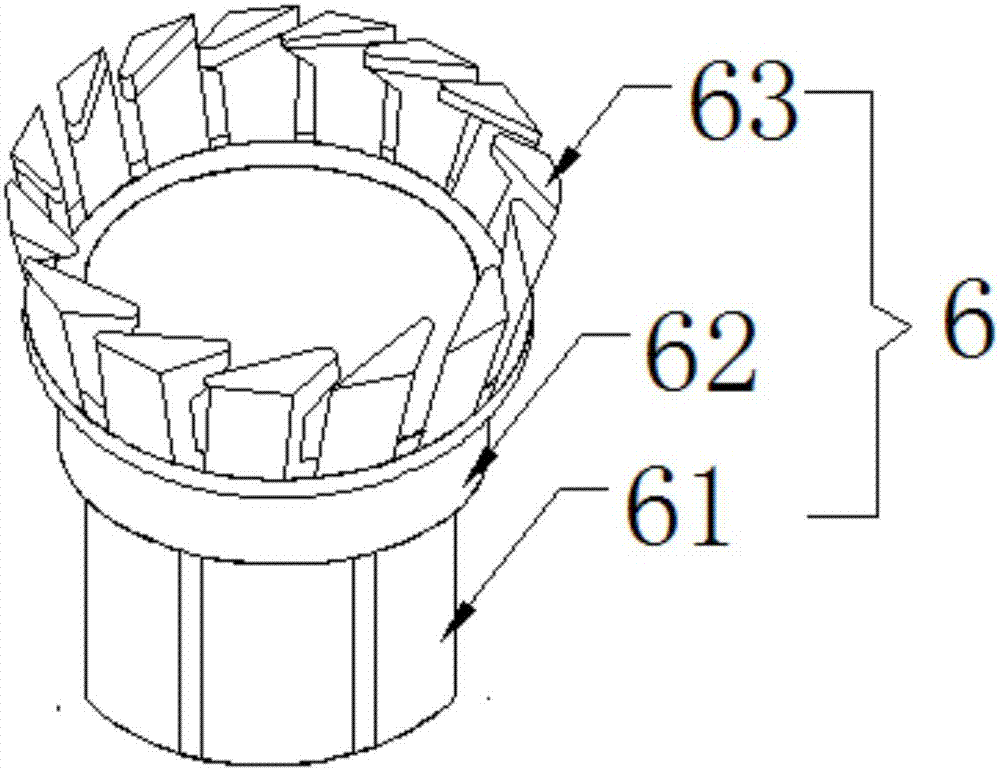

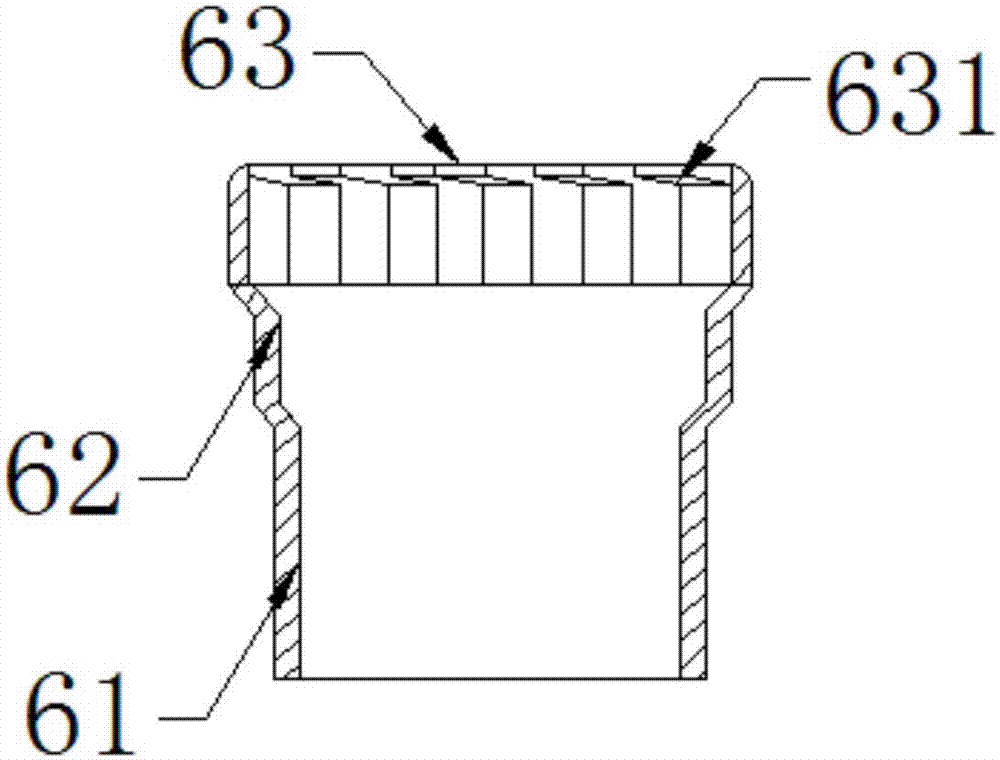

[0021] Such as Figure 1-5 As shown, a cable gland of the present invention includes a cable gland 1 and a nut 2 at one end of the cable gland 1, and the other end of the nut 2 is threadedly connected with a threaded sleeve body 4 through a first O-shaped waterproof ring 3, and the threaded sleeve body The other end of 4 is threadedly connected with a breaking head 8 through the second O-type waterproof ring 10, and the nut 2, the first O-type waterproof ring 3, the threaded sleeve main body 4, the second O-type waterproof ring 5 and the breaking head 8 are connected from the Connected in turn from left to right, the inner cavity between the threaded sleeve main body 4 and the breaking head 8 is provided with an inner clamp 6, the inner clamp 6 includes a lower sleeve 61, and the lower sleeve 61 is connected to the middle sleeve 62 with a port, and The other port of the middle sleeve 62 is connected with clamping jaws 63 evenly distributed in the ring. The upper end of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com