A preparation method of embedded porous pd/c nanoframe and its obtained material and application

An embedded and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of degradation, electrocatalytic performance and stability attenuation, carrier corrosion performance, etc., to achieve good electrical Chemical stability, high electrocatalytic activity and stability, and the effect of improving electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

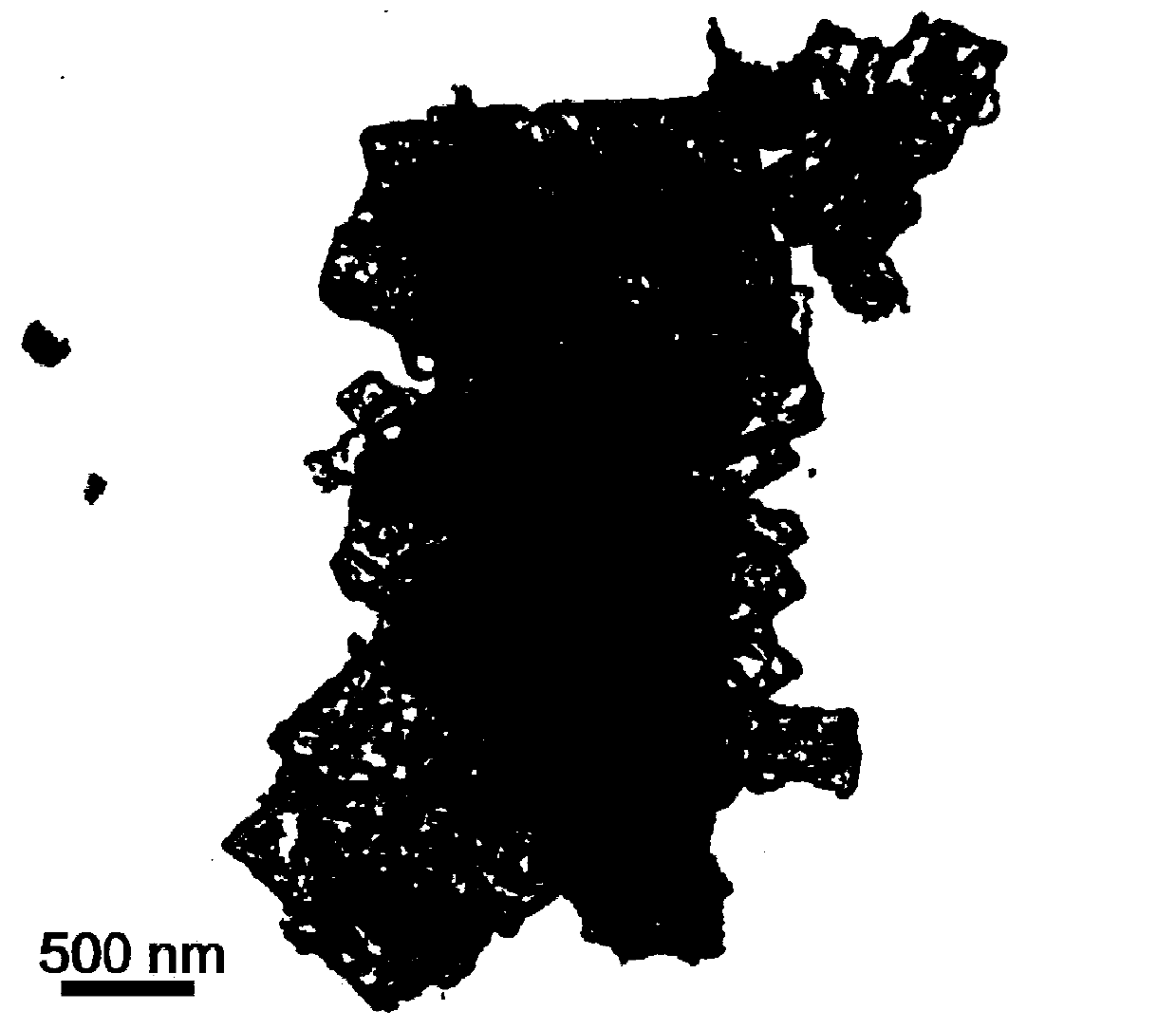

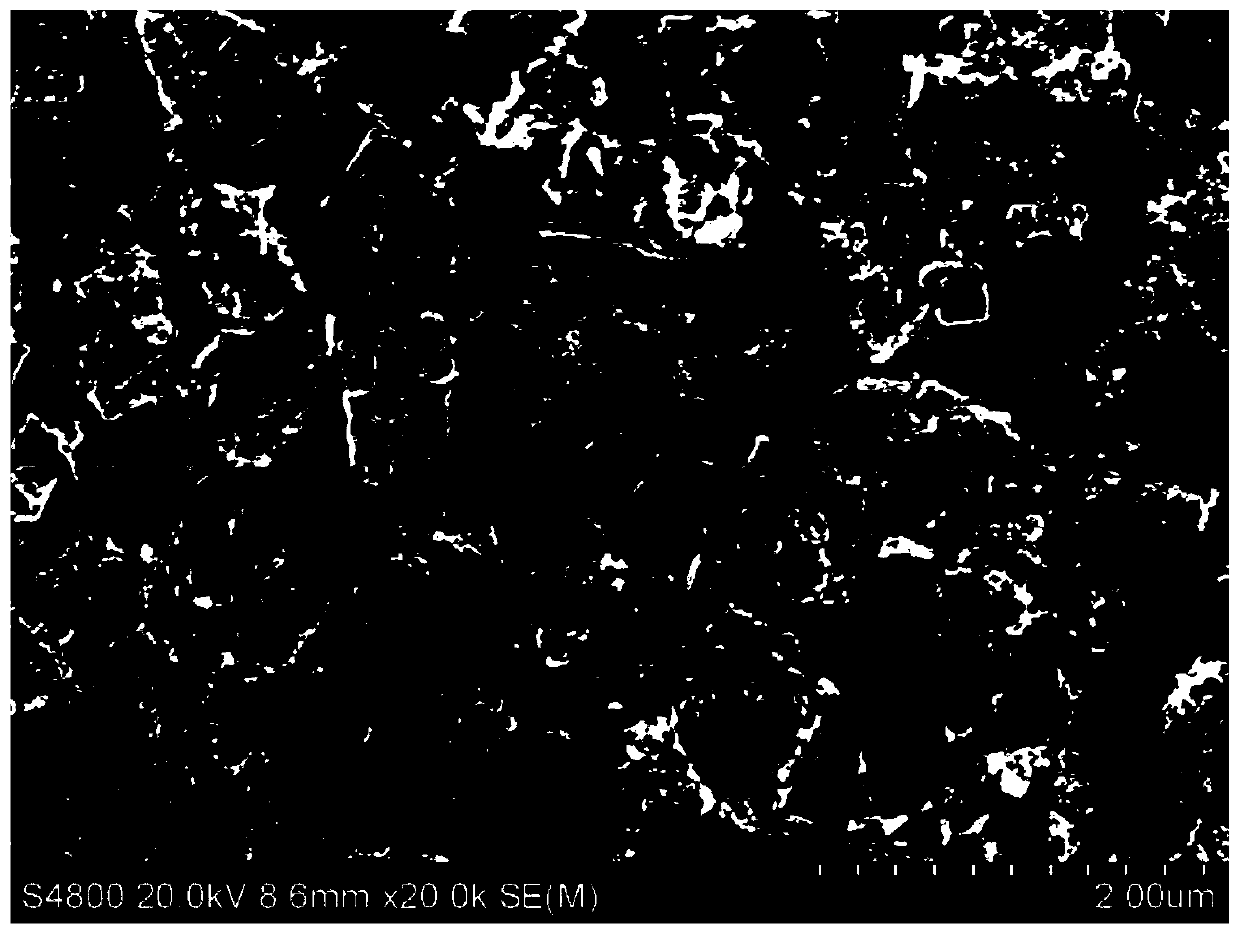

[0032] A preparation method of embedded porous Pd / C nano frame, comprising the following steps:

[0033] 1) Preparation of metal precursor complex: weigh 0.14g naphthylamine (C 10 h 9 N), add 30mL water: ethanol is 0.1:1 in the mixed solvent, fully sonicate it to dissolve; Add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, after standing still, yellow flake Pd(II)-naphthylamine complex can be obtained, which is centrifuged and dried;

[0034] 2) Preparation of embedded porous Pd / C nanoframes: the yellow powder prepared in step 1) was heated at 5°C·min under a nitrogen atmosphere -1 The temperature was raised to 600° C. for heat treatment, kept at this temperature for 3 hours, and then cooled to room temperature to obtain the final product.

Embodiment 2

[0036] A preparation method of embedded porous Pd / C nano frame, comprising the following steps:

[0037] 1) Preparation of metal precursor complex: weigh 0.14g naphthylamine (C 10 h9 N), add 30mL water: ethanol is in the mixed solvent of 99:1, fully ultrasonic makes it dissolve; Add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, after standing still, yellow flake Pd(II)-naphthylamine complex can be obtained, which is centrifuged and dried;

[0038] 2) Preparation of embedded porous Pd / C nanoframes: the yellow powder prepared in step 1) was heated at 5°C·min under a nitrogen atmosphere -1 The temperature was raised to 600° C. for heat treatment, kept at this temperature for 3 hours, and then cooled to room temperature to obtain the final product.

Embodiment 3

[0040] A preparation method of embedded porous Pd / C nano frame, comprising the following steps:

[0041] 1) Preparation of metal precursor complex: weigh 0.002g naphthylamine (C 10 h 9 N), add 30mL of water: ethanol is a 1:1 mixed solvent, fully ultrasonic to make it dissolve; add 4mL 0.05mol L -1 PdCl 2 Aqueous solution, after standing still, yellow flake Pd(II)-naphthylamine complex can be obtained, which is centrifuged and dried;

[0042] 2) Preparation of embedded porous Pd / C nanoframes: the yellow powder prepared in step 1) was heated at 5°C·min under a nitrogen atmosphere -1 The temperature was raised to 600° C. for heat treatment, kept at this temperature for 3 hours, and then cooled to room temperature to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com