Convenient self-suction type sand sieving equipment for building

A self-priming, construction technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high labor intensity, increase construction cost, inconvenient to move, etc., to reduce labor intensity, improve work efficiency, avoid sand spill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

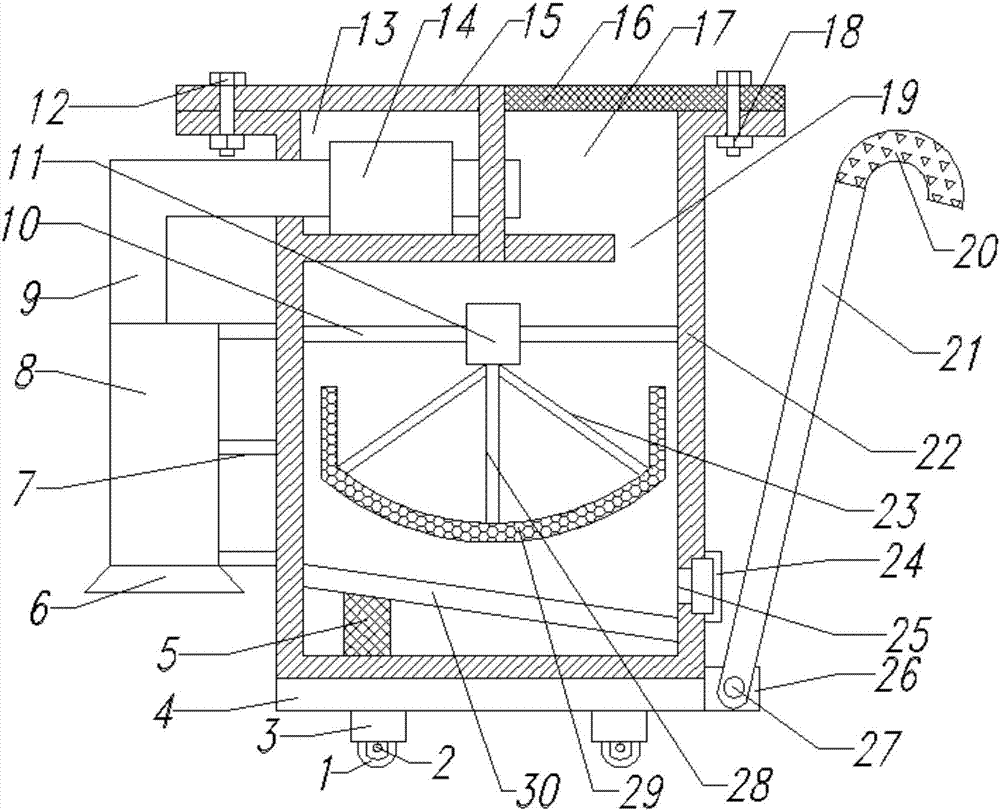

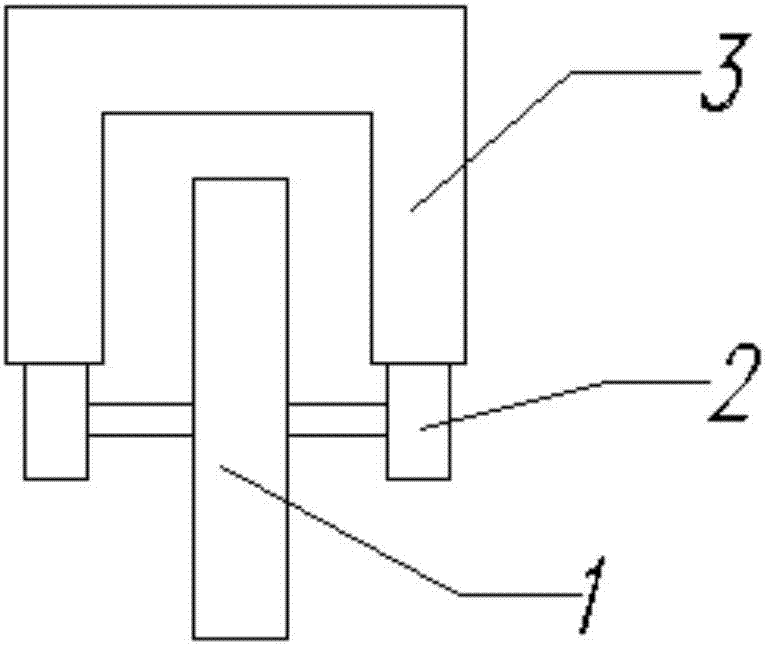

[0015] see Figure 1-2 , a kind of convenient self-priming sand screening equipment for construction, including wheel 1, feeding cover 6, sand suction pipe 9, fixed rod 10, U-shaped leaking screen 29, push rod 21 and housing 22; the wheel support frame 3 is fixedly arranged under the bottom plate 4; the wheel 1 is arranged under the wheel support frame 3 through the wheel connecting shaft 2, so that the device has mobility; the connecting piece 26 is fixedly arranged at the right lower end of the bottom plate 4; The push rod 21 is connected with the connecting piece 26 through the rotating shaft rod 27, and is rotatable. It is made of steel pipe material; Patterned rubber sleeve; the bottom plate 4 is fixedly provided with a housing 22; the left side of the housing 22 is provided with a telescopic device fixing rod 7; the telescopic device fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com