Arm type laser machine

A laser machine and arm technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cumbersome structure, huge volume, high load requirements of mobile modules, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0023] In this embodiment, an arm-type laser machine is provided, and the arm-type structure can also be used in other devices with optical paths.

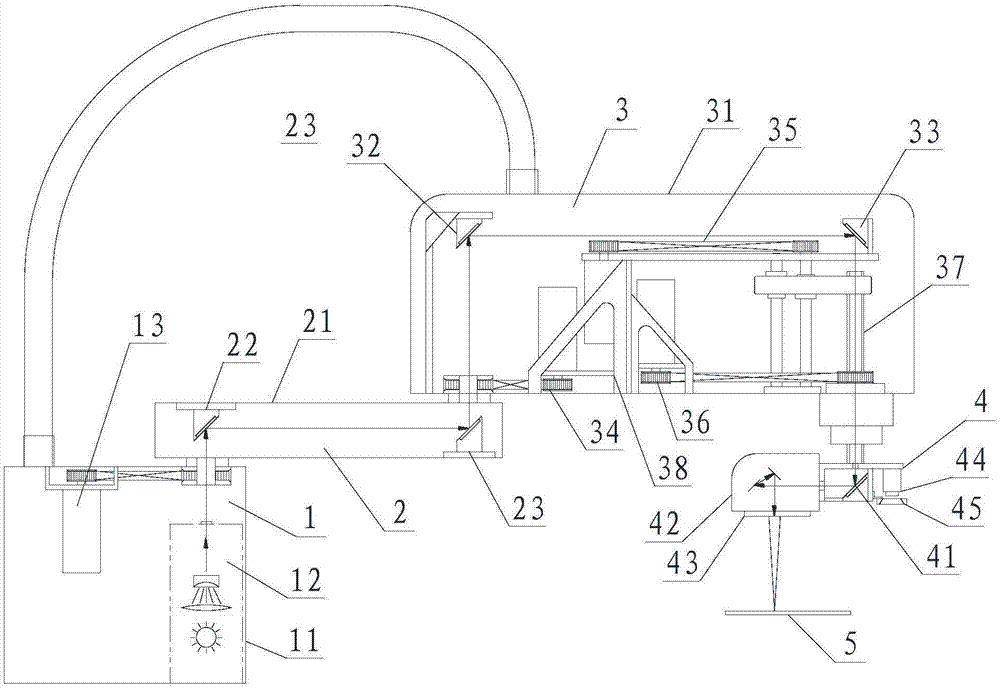

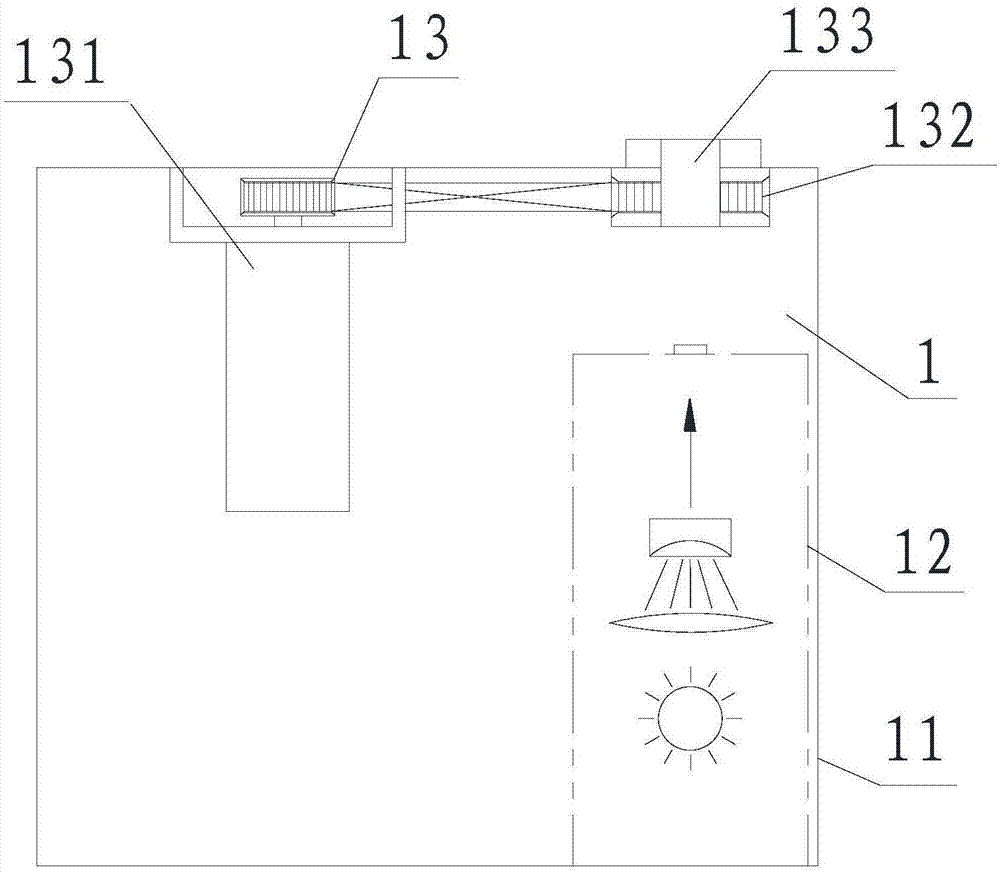

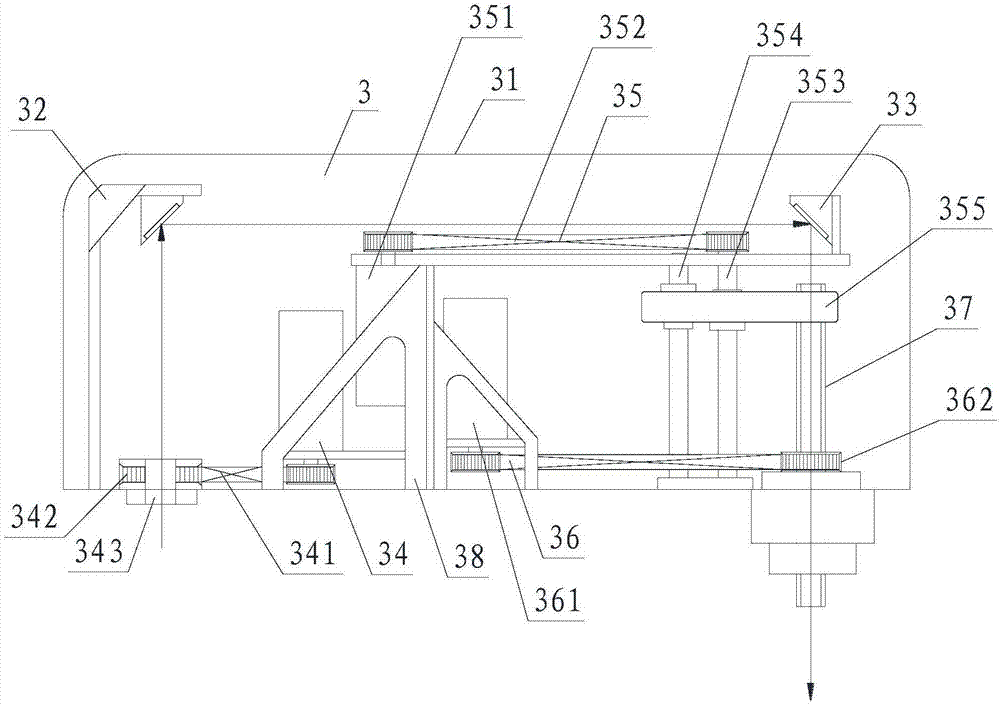

[0024] Such as figure 1 As shown, the arm-type laser machine of this embodiment includes an A-axis base assembly 1, a B-axis base assembly 2, a C-axis base assembly 3 and a lens module 4 (ie, a working head), and the A-axis base assembly 1 is fixed In the preset position, the B-axis base assembly 2 is installed on the A-axis base assembly 1 for rotation along the A-axis, and the C-axis base assembly 3 is installed on the B-axis base assembly 2 for rotation along the B-axis The lens module 4 is mounted on the C-axis base assembly 3 for rotation and axial movement along the C axis, so that the lens module 4 can move along the X, Y, and Z axes and rotate along the Z axis. A flexible pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap