Six-axis robot

A six-axis robot and elbow technology, applied in the field of automation, can solve the problems of limited rotation angle, not meeting energy saving and environmental protection, and the overall shape of the robot is bloated and large, and achieves the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

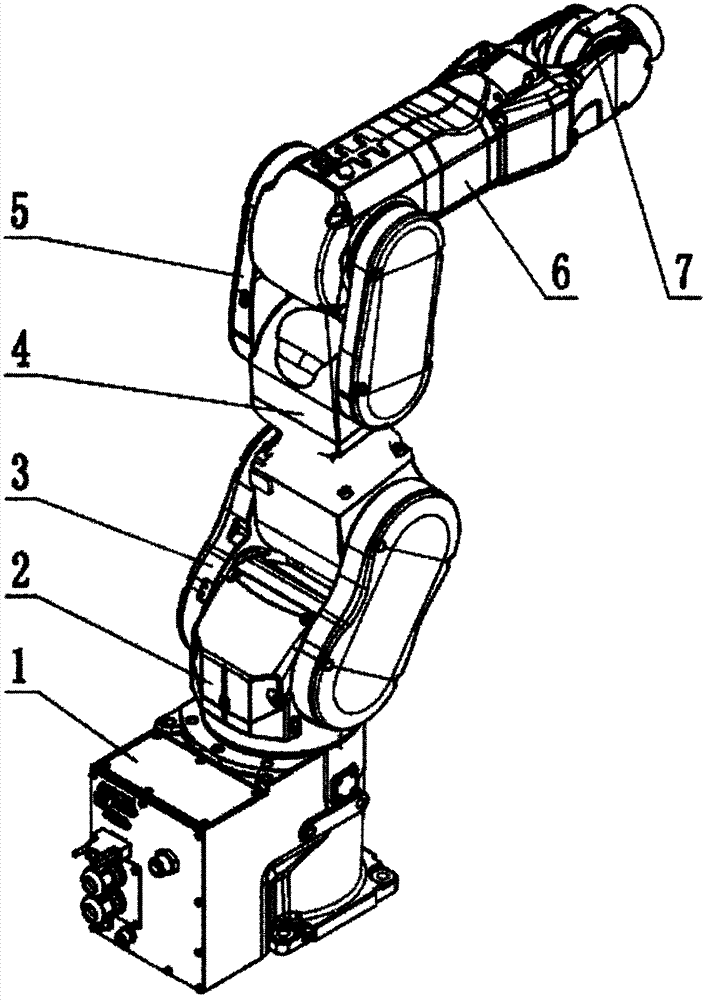

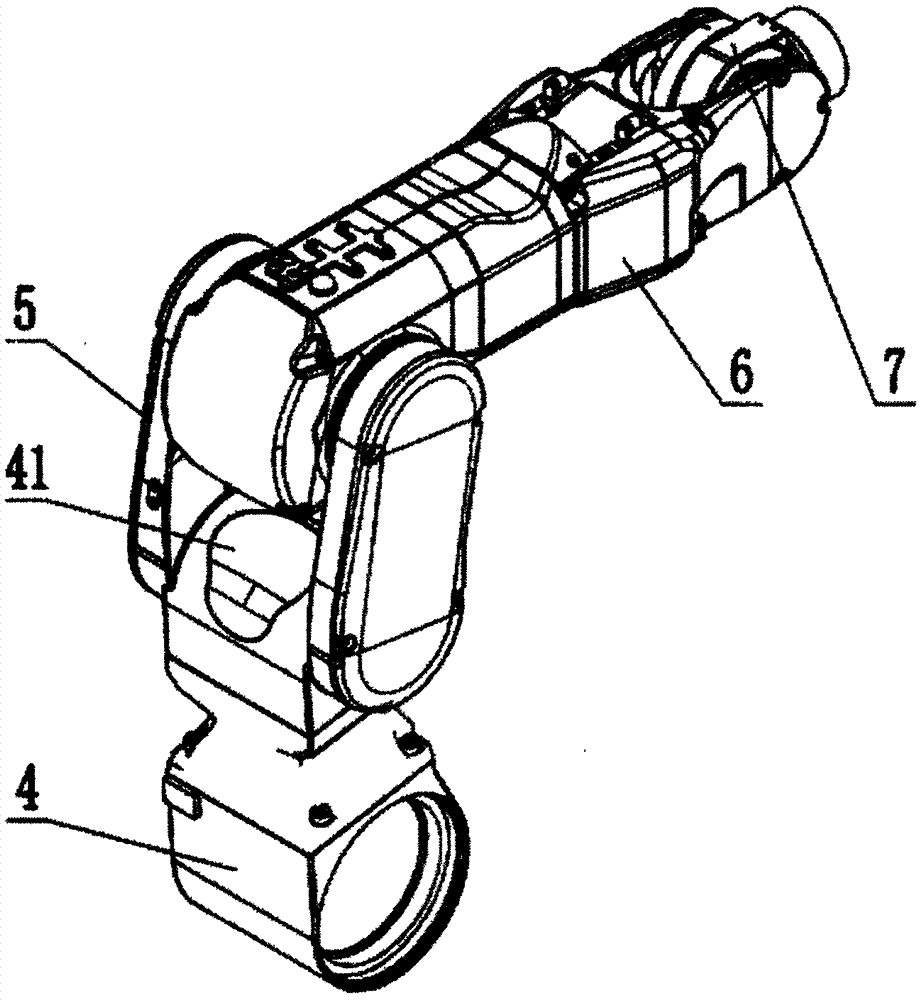

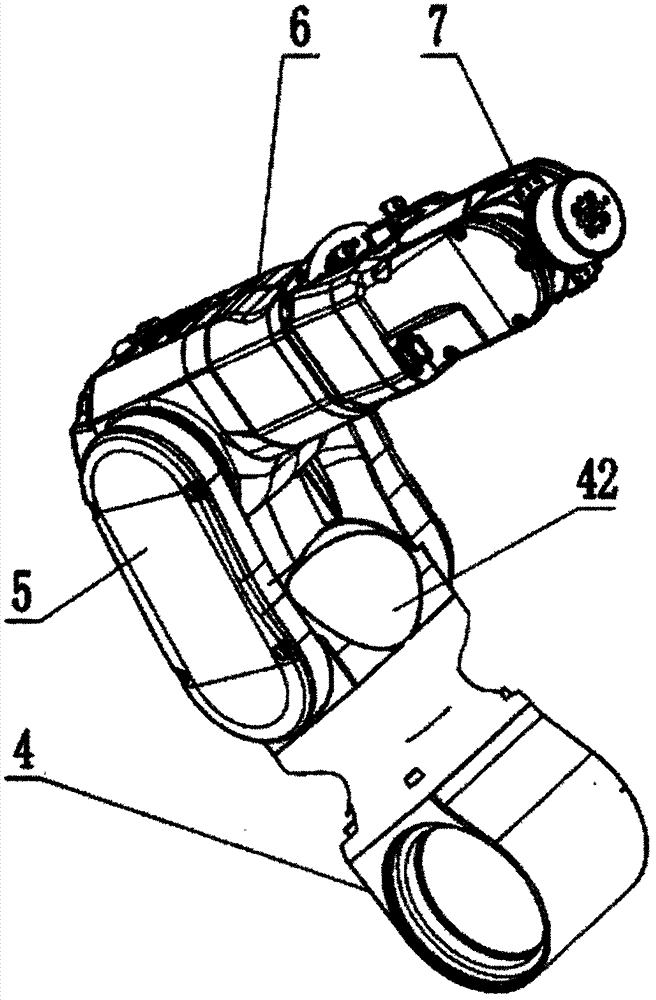

[0023] In the embodiment, as attached figure 1 , attached Image 6 As shown, a six-axis robot includes a base 1, and a shoulder 2, a large arm 3, an elbow 4, a forearm 5, a wrist 6 and a hand 7 installed on the base 1 in sequence, and the elbow The upper arm 4 is a double-joint structure, and the upper arm 3 and the lower arm 5 are respectively hinged at the two ends of the elbow 4 . The double-joint elbow 4 of this embodiment increases the rotation angle of the six-axis robot on the same plane without increasing the rotation axis and ensuring sufficient degrees of freedom of the robot, and does not increase the overall size of the robot, and is especially suitable for small working environment, expanding the scope of use of six-axis robots. The range of motion of its hand 7 in the plane is as attached Image 6 As shown by the double dotted line in , it is much larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com