Patents

Literature

32results about How to "No size increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

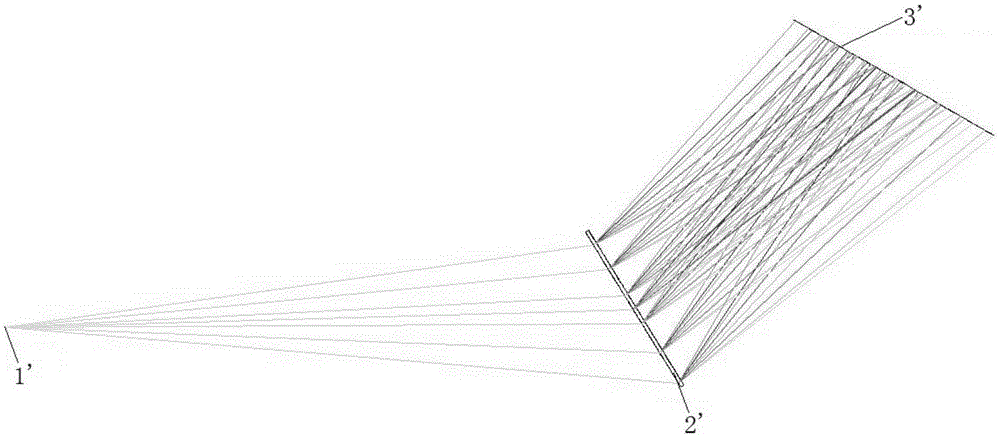

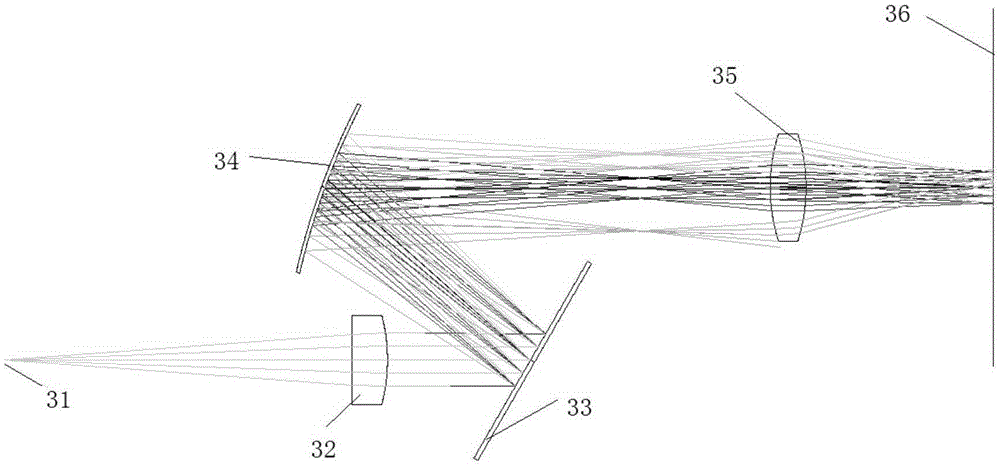

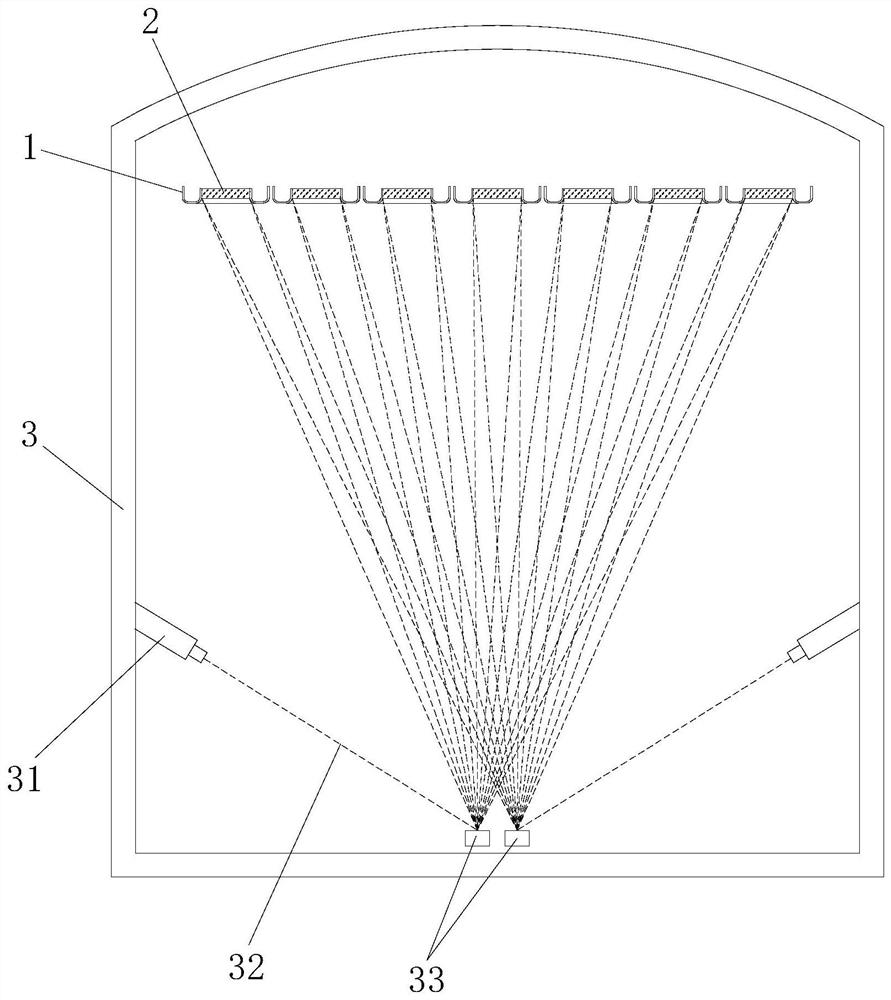

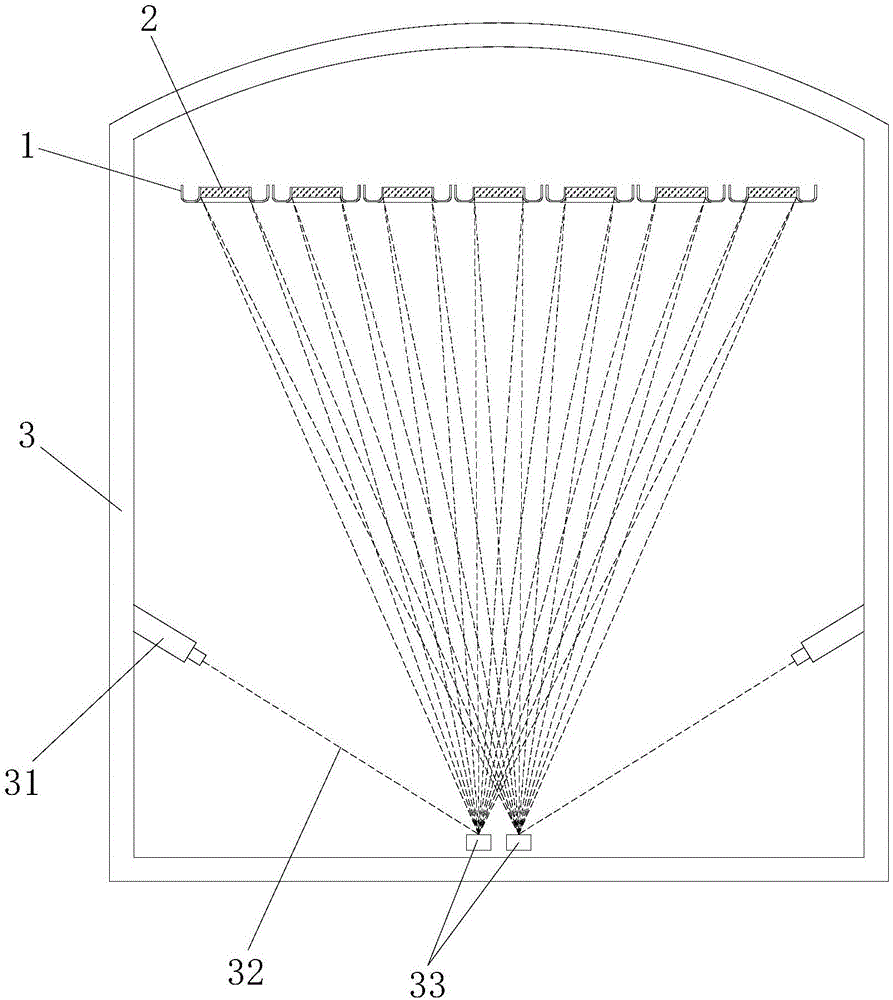

Mobile phone spectrograph module and mobile phone spectrograph with mobile phone spectrograph module

ActiveCN104062007AGood spectral resolutionSimple and square shapeSpectrum investigationGratingImage resolution

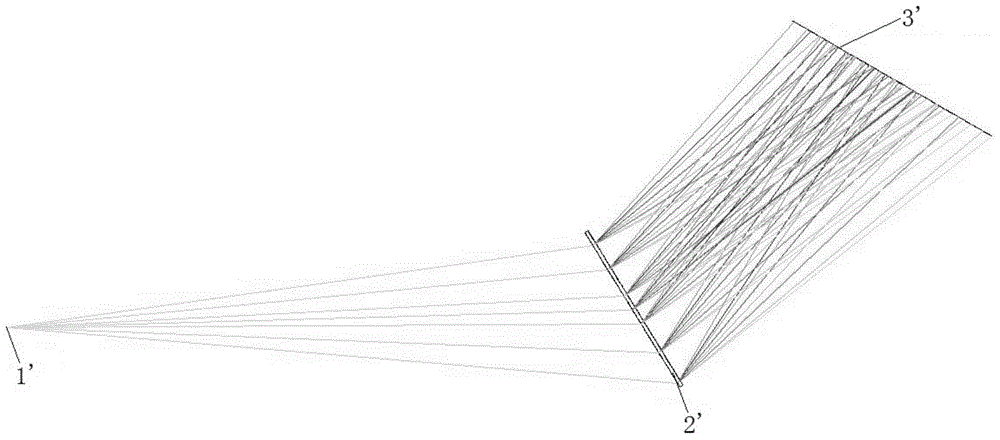

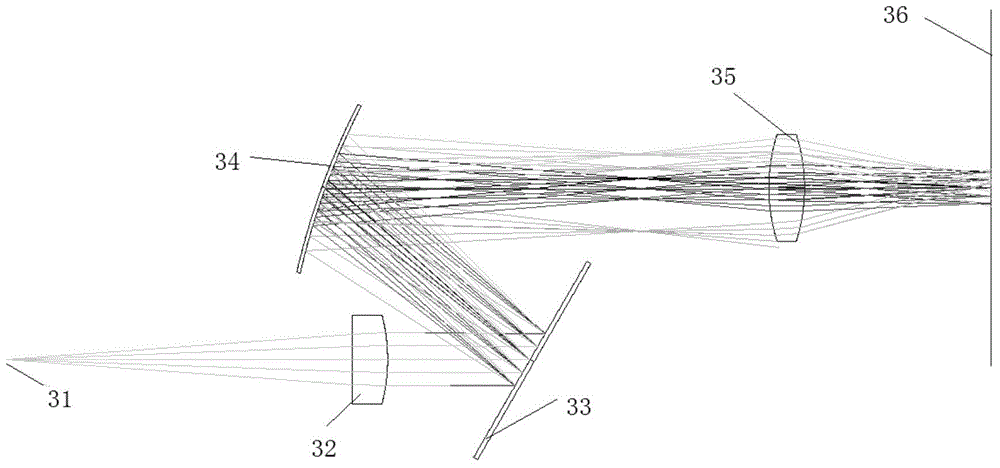

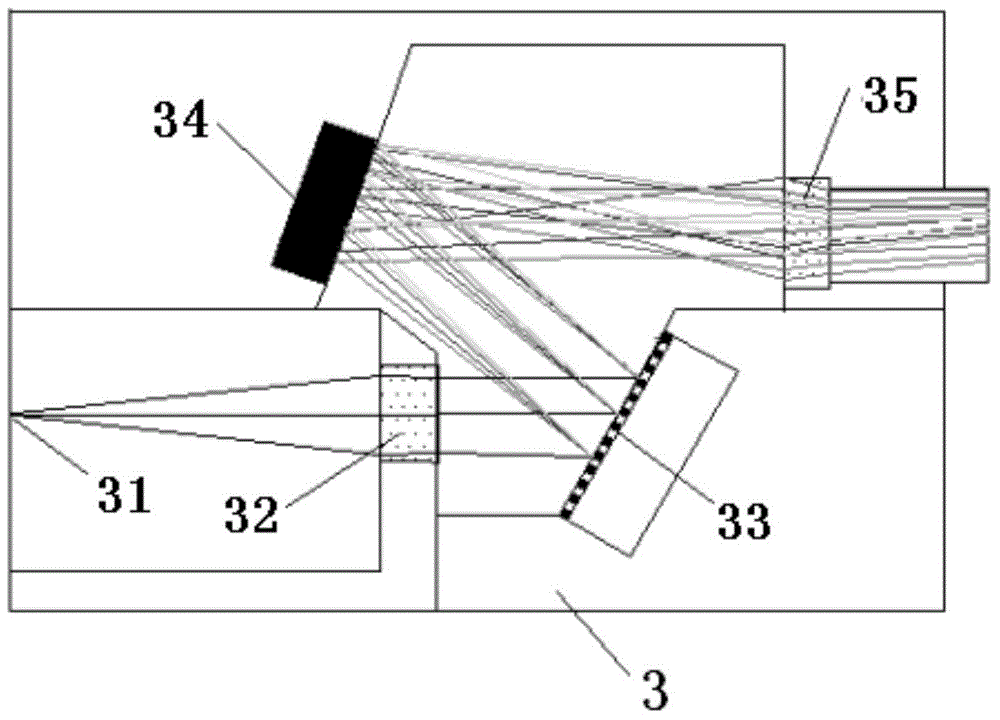

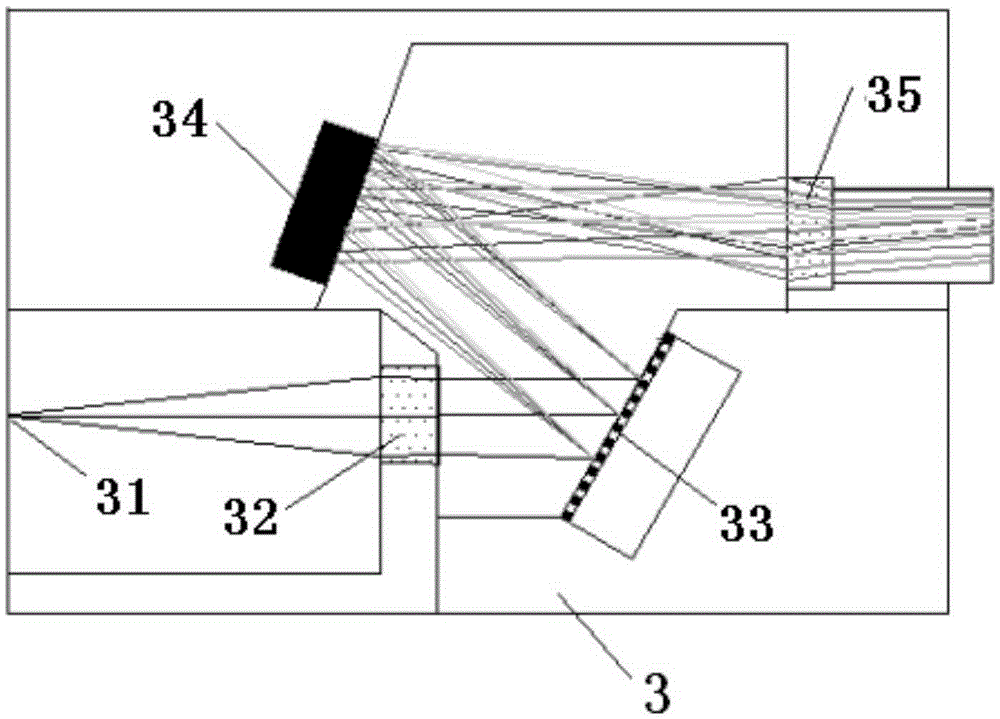

The invention is suitable for the technical field of spectrographs, and discloses a mobile phone spectrograph module and a mobile phone spectrograph with the mobile phone spectrograph module. The mobile phone spectrograph module comprises a shell with a slit. A plane-convex collimating lens used for collimating light rays entering the slit is arranged in the shell. A reflecting grating used for reflecting the light rays collimated by the plane-convex collimating lens and changing the incident polychromatic light into monochromatic light emitted in different directions is arranged on one side of the plane-convex collimating lens. A spherical reflecting mirror used for gathering the monochromatic light emitted by the reflecting grating is further arranged in the shell. A biconvex lens is arranged between the spherical reflecting mirror and the receiving face of a mobile phone camera. The mobile phone spectrograph comprises a mobile phone and the mobile phone spectrograph module. The mobile phone spectrograph module and the mobile phone spectrograph with the mobile phone spectrograph module are high in spectral resolution, compact in structure, easy to install and capable of being easily expanded and externally arranged.

Owner:SHENZHEN INST OF ADVANCED TECH

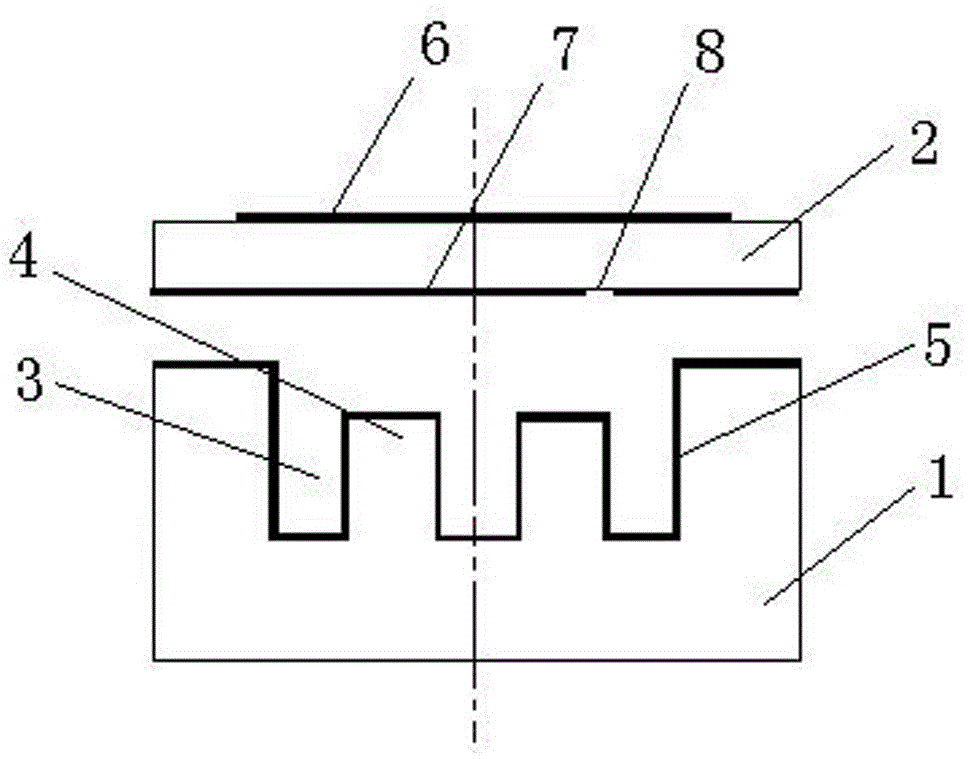

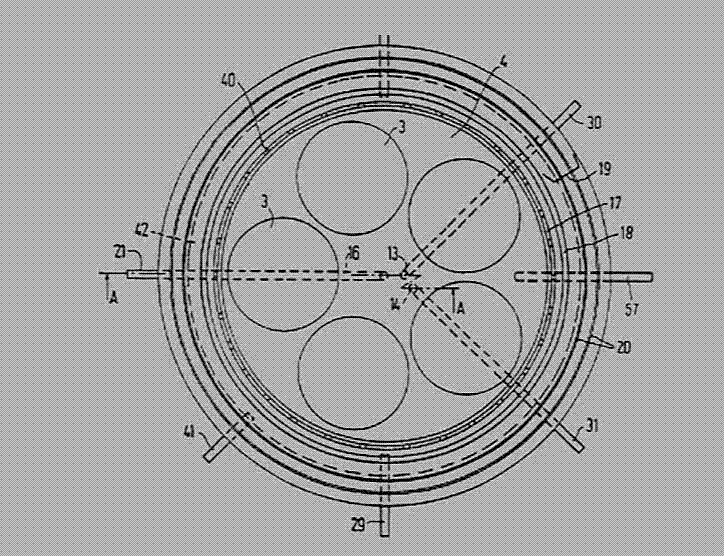

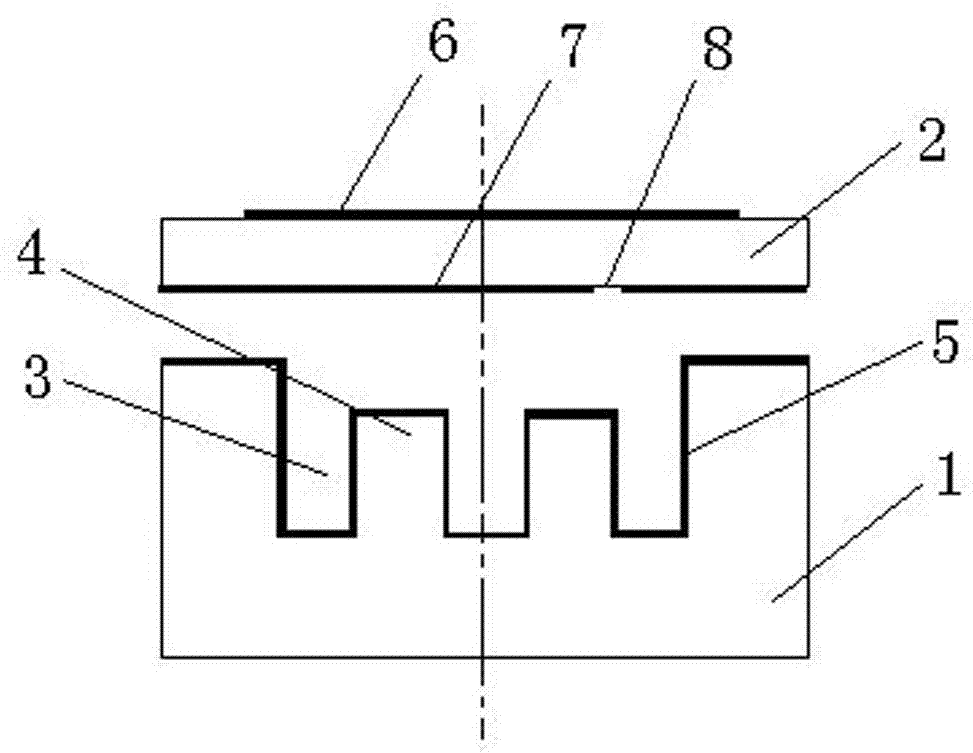

A passive high-temperature voltage sensor utilizing the microwave scattering principle, and a preparation method thereof

ActiveCN105004469AReduce lossIncrease distanceFluid pressure measurement by electric/magnetic elementsHigh pressureHigh voltage

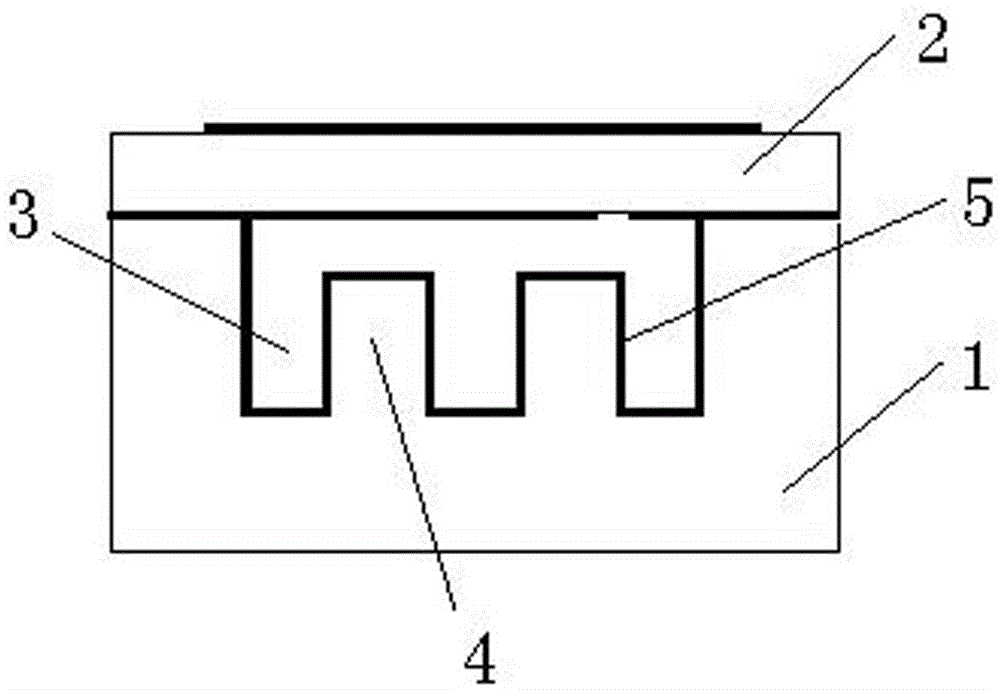

The invention relates to the technical field of voltage sensors, concretely relates to a passive high-temperature voltage sensor utilizing the microwave scattering principle and also a preparation method thereof, and helps to solve the problems that a conventional voltage measuring method has many defects in high-temperature and other severe environments. The passive high-temperature voltage sensor includes a cylindrical pedestal and a sealing membrane. A concave cylindrical cavity is disposed inside the pedestal. Four symmetrical cylinders are disposed in the middle of the concave cylindrical cavity, and the height of each inner cylinder is lower than the upper surface of the concave cylindrical cavity. The upper surface of the pedestal, the inner surface of the concave cylindrical cavity and the upper surface of each inner cylinder are all equipped with metal layers through sputtering. A silk screen on the upper surface of the sealing membrane is provided with a microstrip antenna through sputtering, a grounding plane is disposed on the entire lower surface of the sealing membrane through sputtering, and the lower surface is equipped with a rectangular coupling slit. The pedestal and the sealing membrane are bonded to form a microwave resonant cavity. The passive high-temperature voltage sensor is reasonable in design and high in sensitivity, exhibits great stability, can work for a long period of time in high-temperature, high-voltage and other severe environments, and belongs to a passive high-temperature ceramic voltage sensor for wireless measuring on the basis of microwave scattering.

Owner:ZHONGBEI UNIV

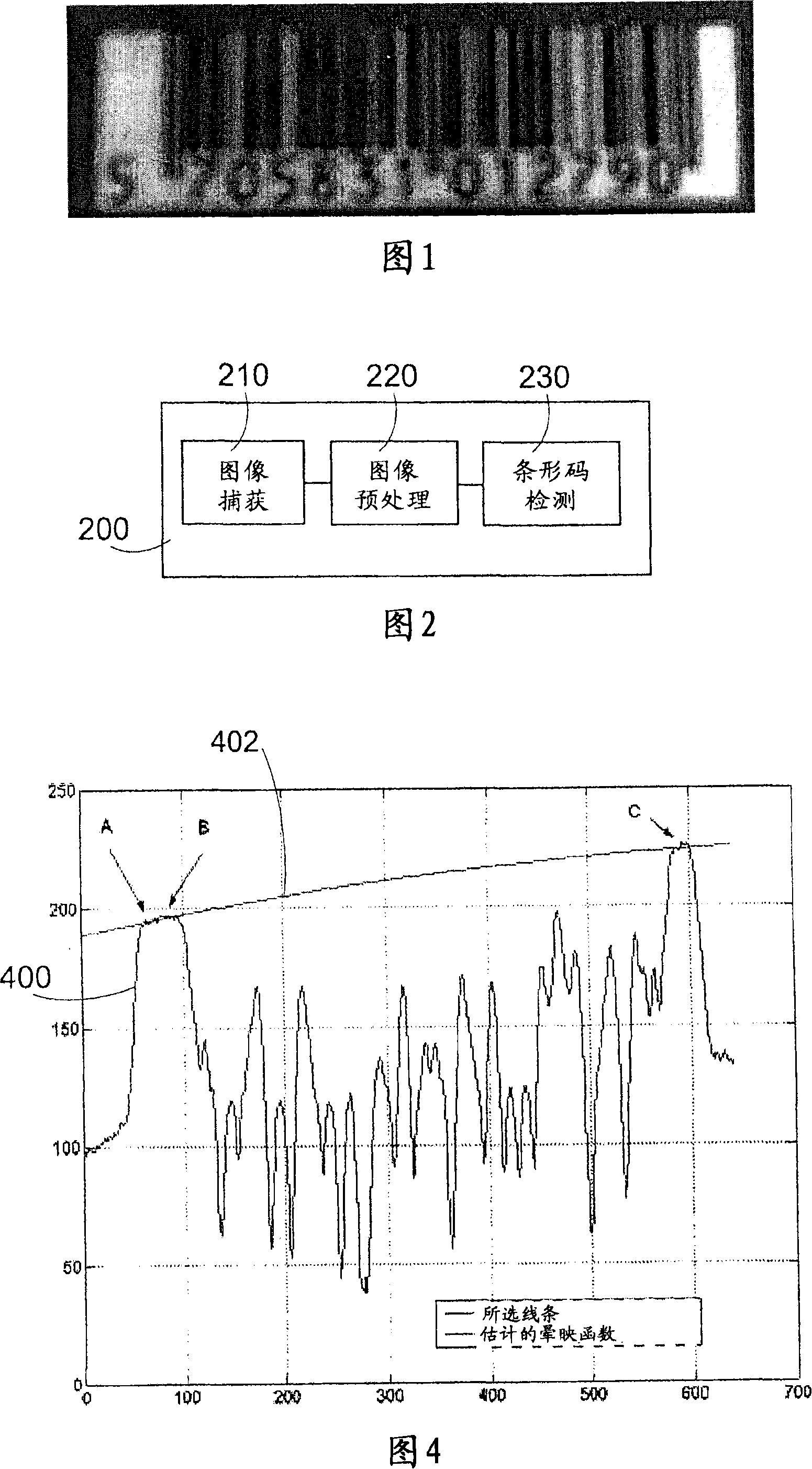

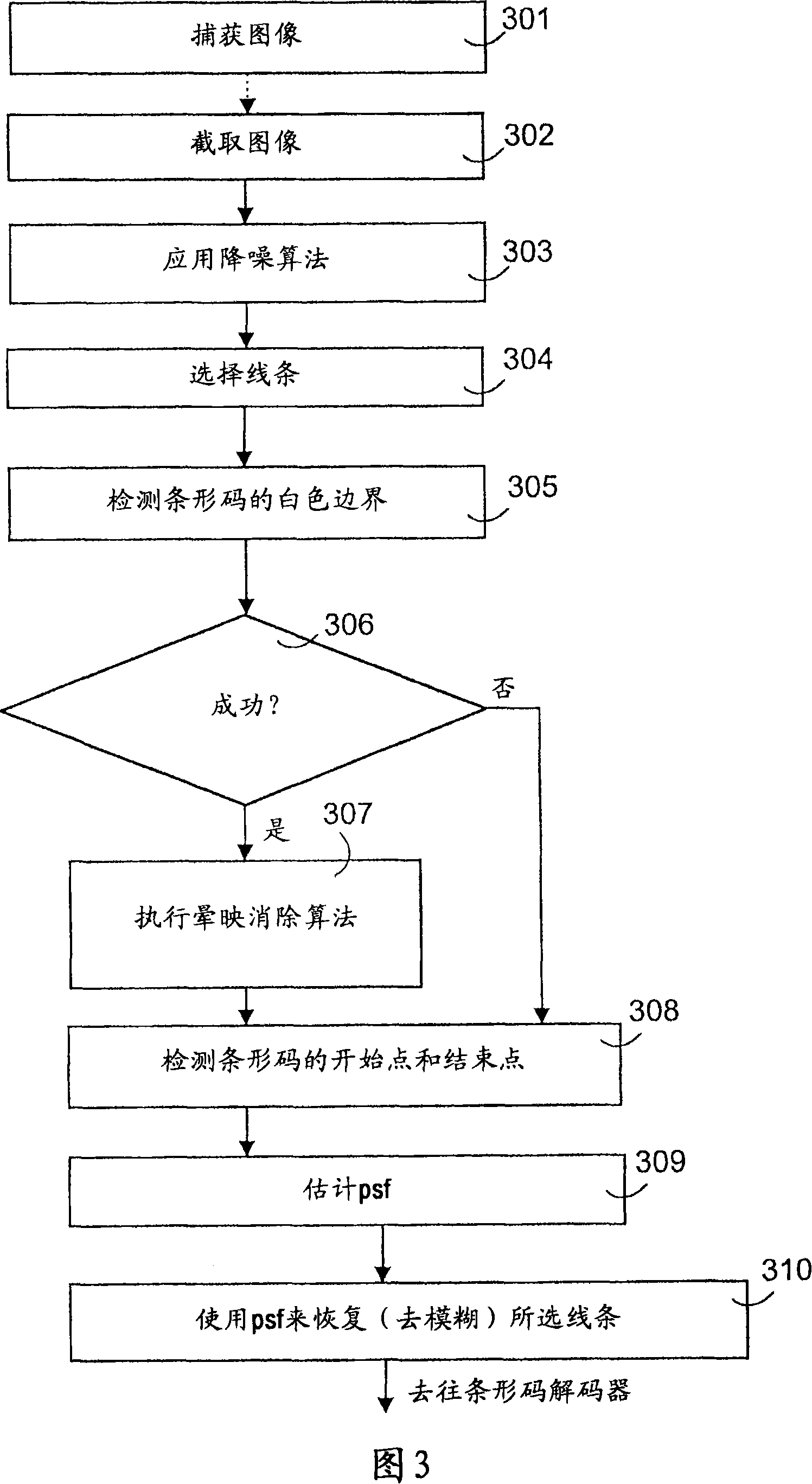

Image processing for pattern detection

InactiveCN101180636AReliable detectionQuick checkImage enhancementImage analysisPattern recognitionImaging processing

The present invention relates to an image pre-processing method for a pattern detection system, such as a bar code detection system. The method comprises the steps of: detecting a start point and an end point of a pattern on the basis of image data of at least a portion of a captured image, estimating a point spread function from the image data or a modified image data on the basis of the detected start point and the end point, and restoring the image data or the modified image data using the estimated point spread function.

Owner:NOKIA CORP

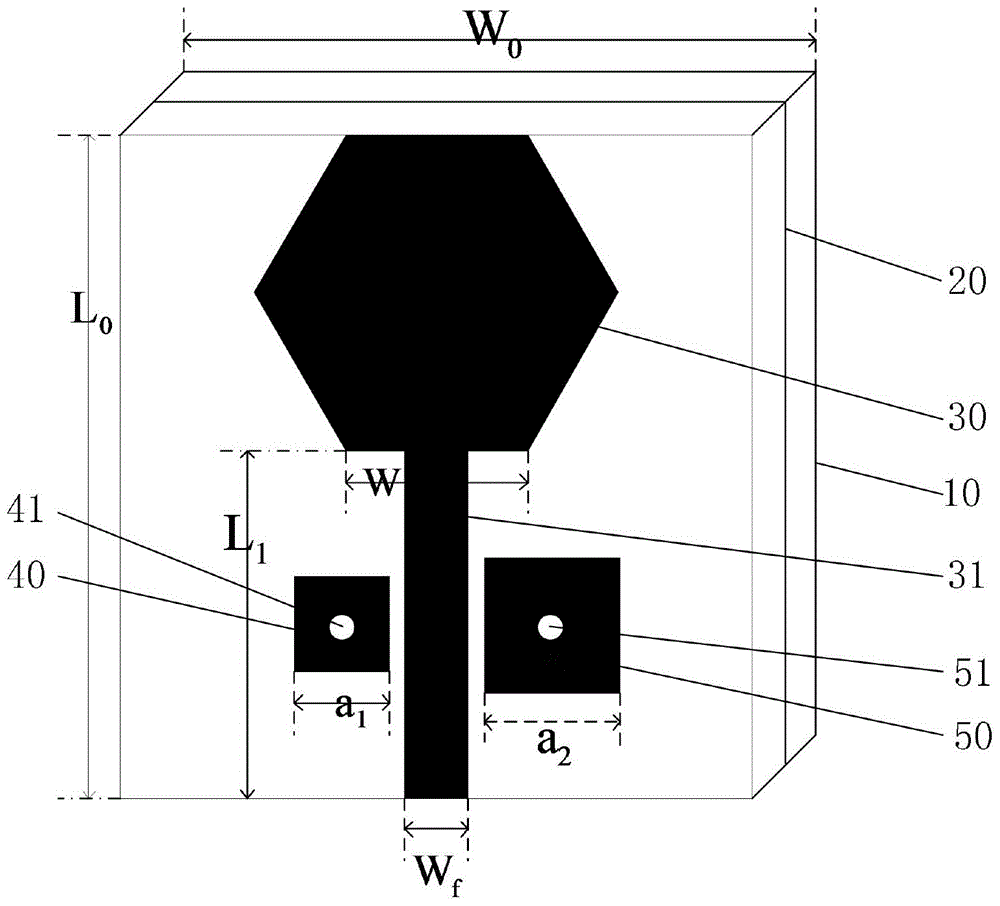

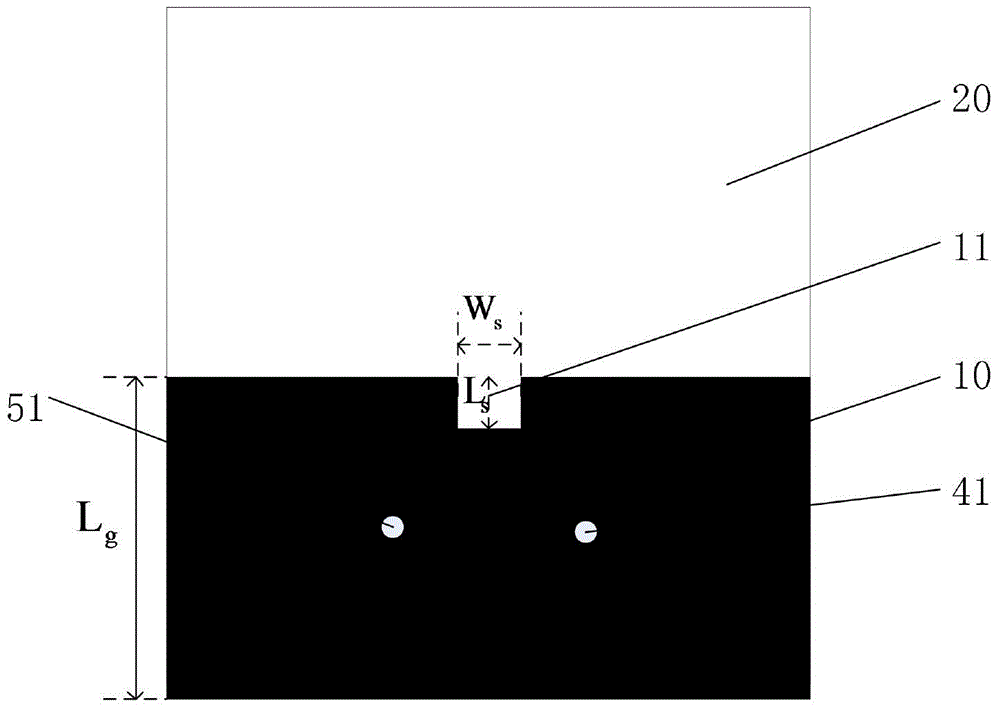

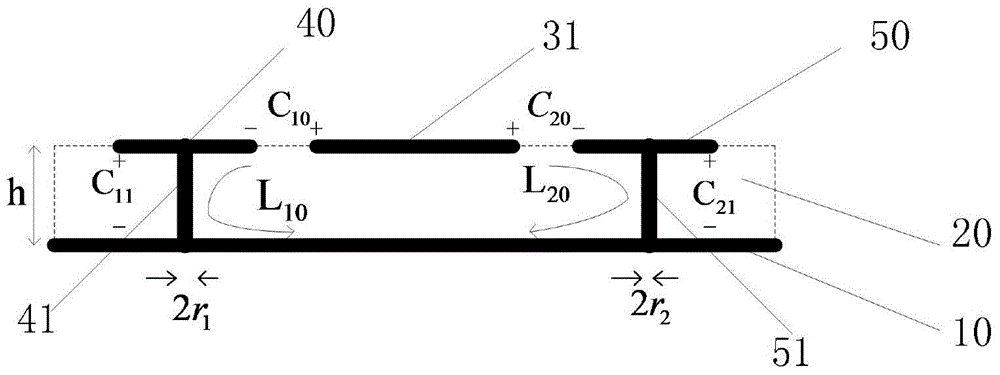

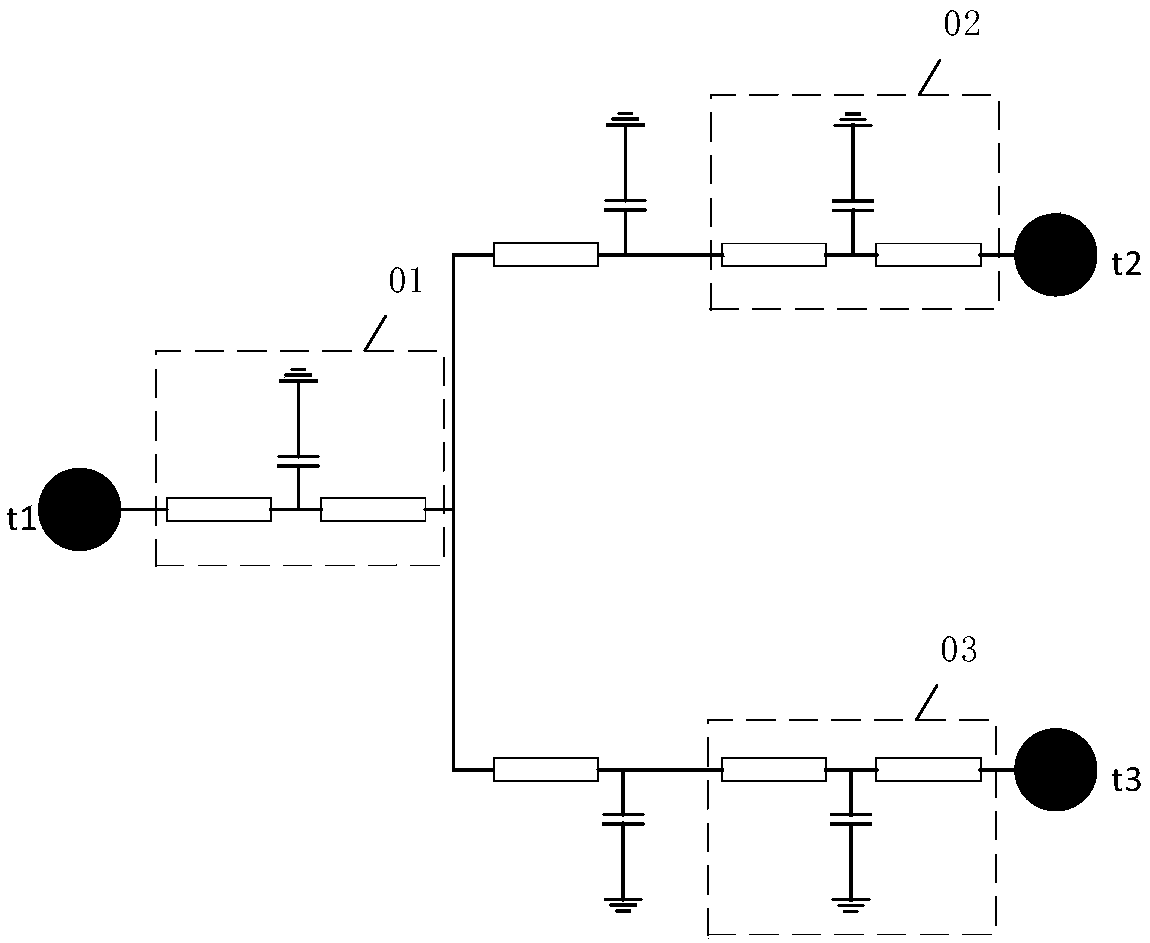

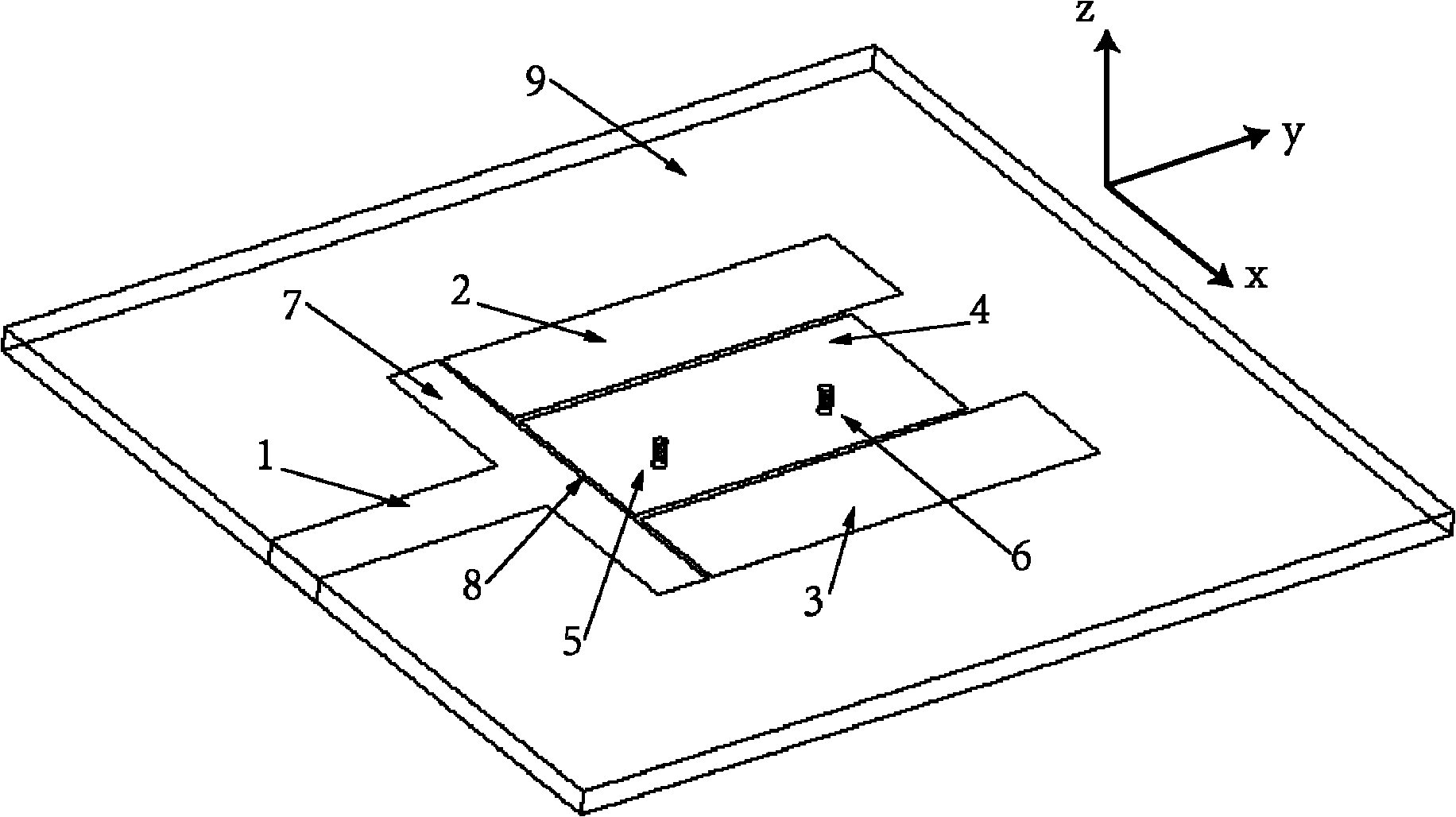

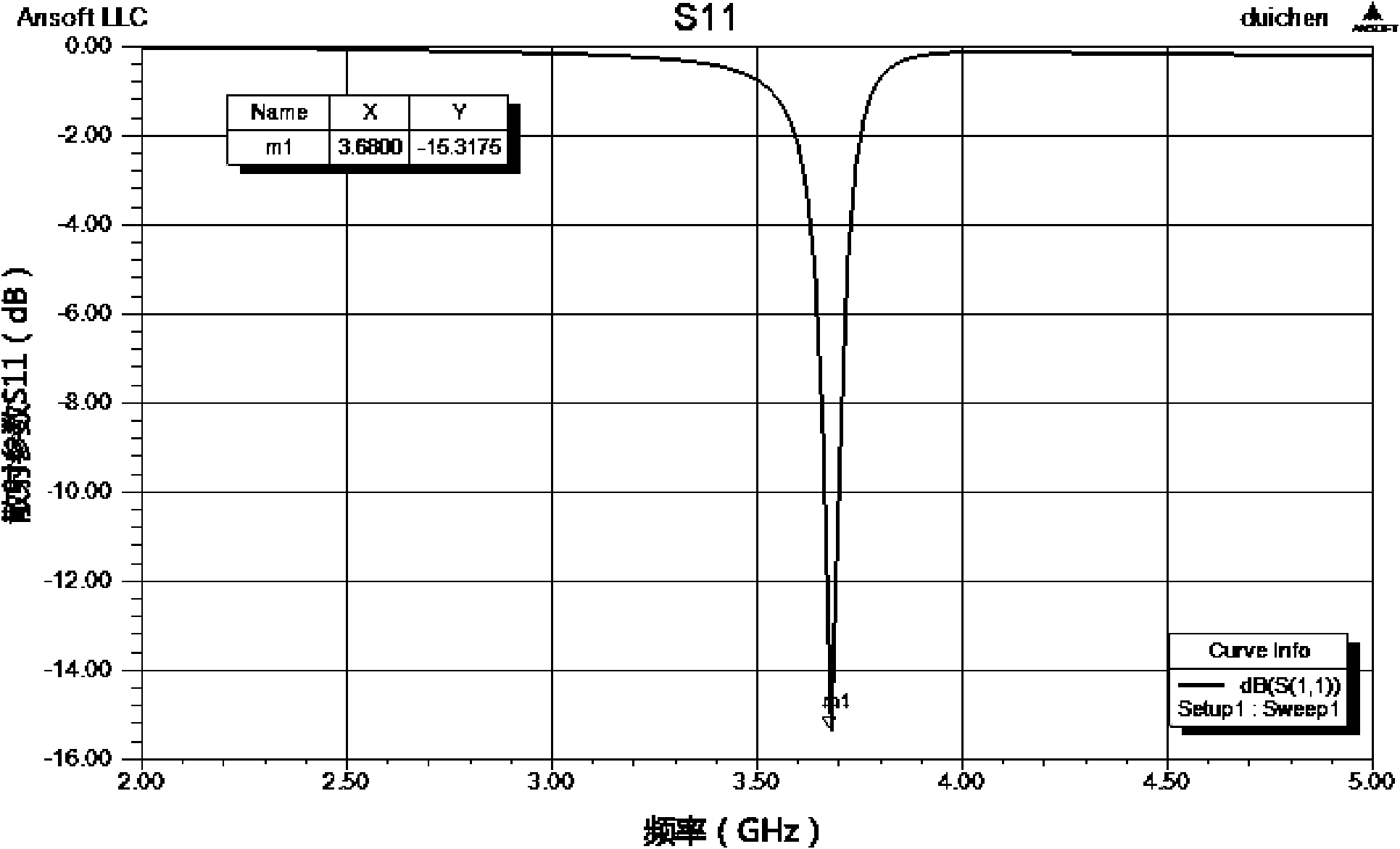

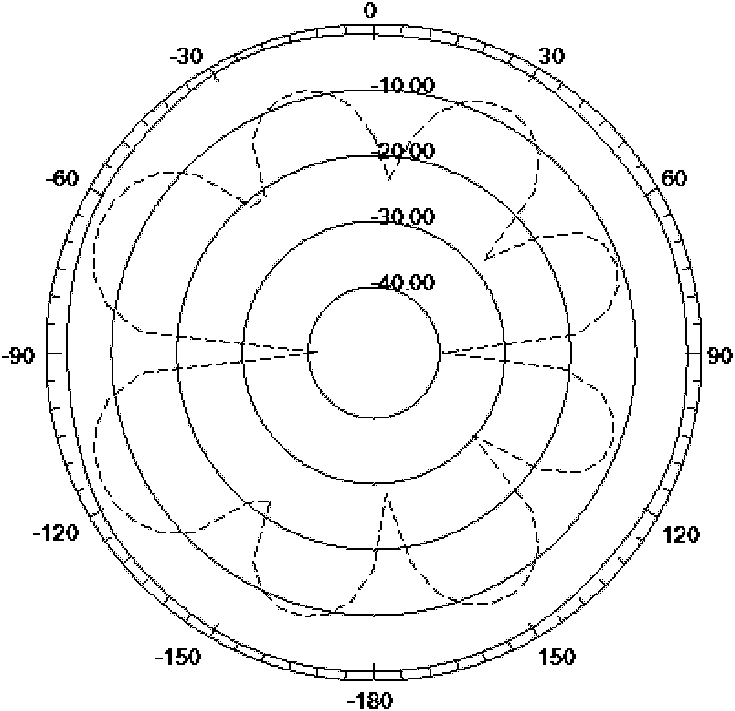

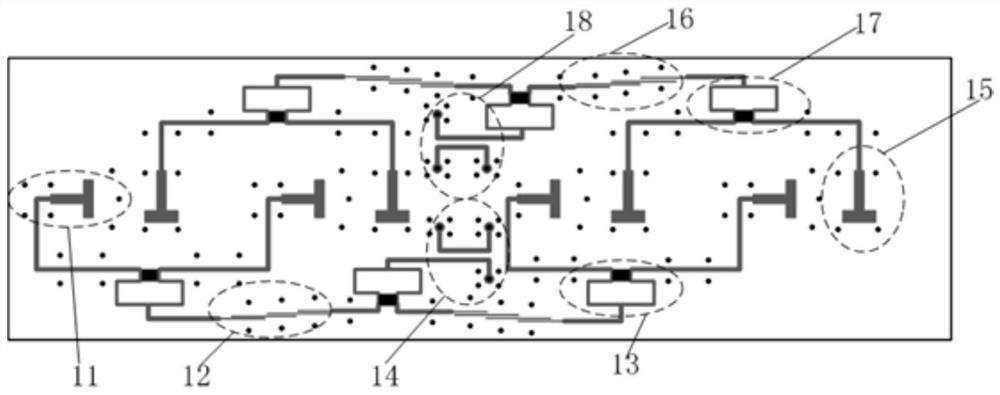

Dual-notch UWB (ultra wide band) antenna based on Mushroom-EBG (electromagnetic band gap) structure

InactiveCN104681949ANo size increaseGuaranteed miniaturizationRadiating elements structural formsAntenna earthingsMicrowaveCommunications system

The invention relates to a dual-notch UWB (ultra wide band) antenna based on a Mushroom-EBG (electromagnetic band gap) structure. The dual-notch UWB antenna comprises a partial metal grounding plate (10), a medium substrate (20), an antenna radiating patch (30), a 50 ohm feeder line (31) and two Mushroom-EBG structure units (40 and 50). The two Mushroom-EBG structure units (40 and 50) with different size parameters are respectively coupled with the 50 ohm feeder line (31) of a regular hexagon-shaped UWB antenna, so the signals of two frequency bands, namely WIMAX (worldwide interoperability for microwave access) and WLAN (wireless local area network), can be effectively filtered out. The dual-notch UWB antenna has the advantages that the antenna has good all-bearing radiating property and stable gain effect in the full frequency band, the notch property is good, and the antenna is suitable for the UWB wireless communication system.

Owner:HARBIN FEIYU TECH

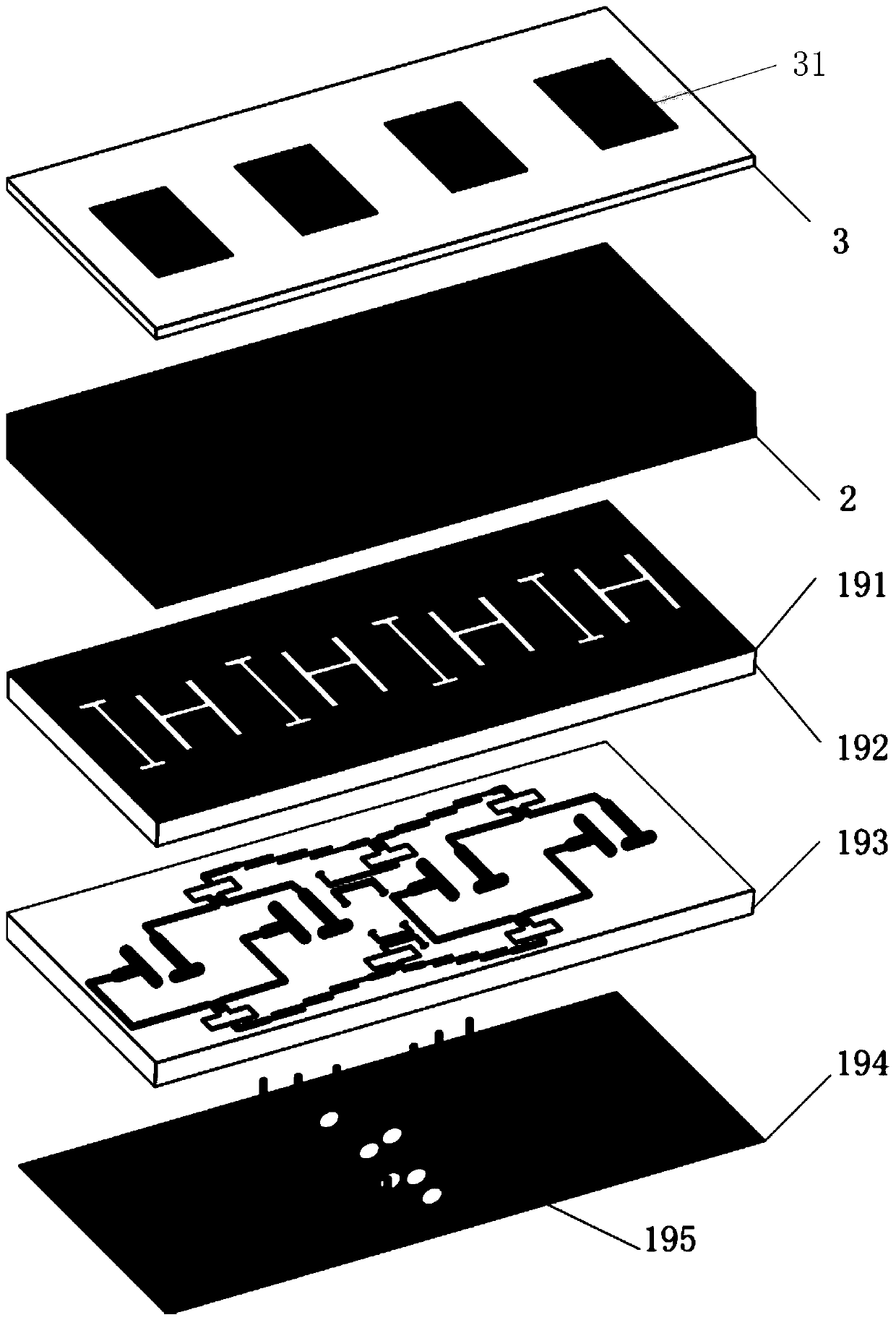

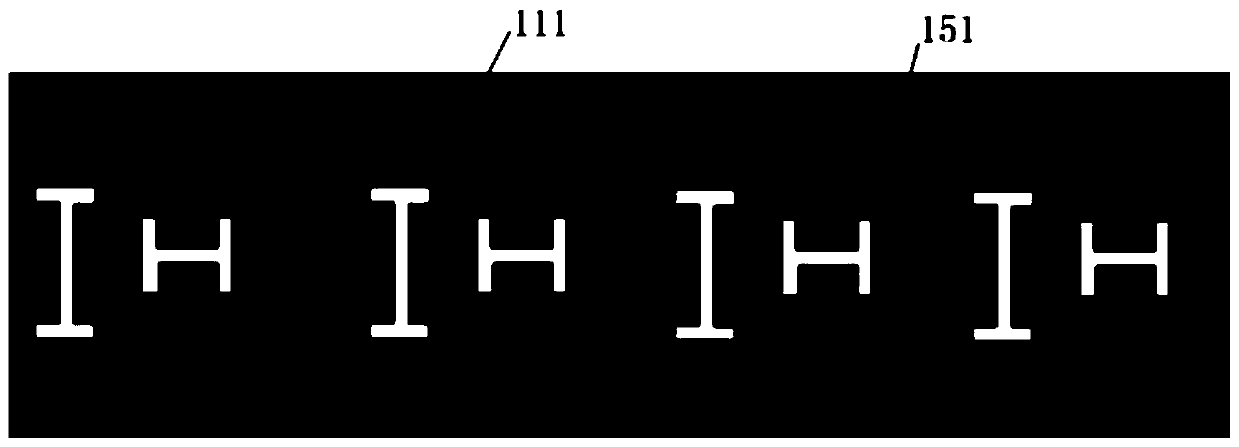

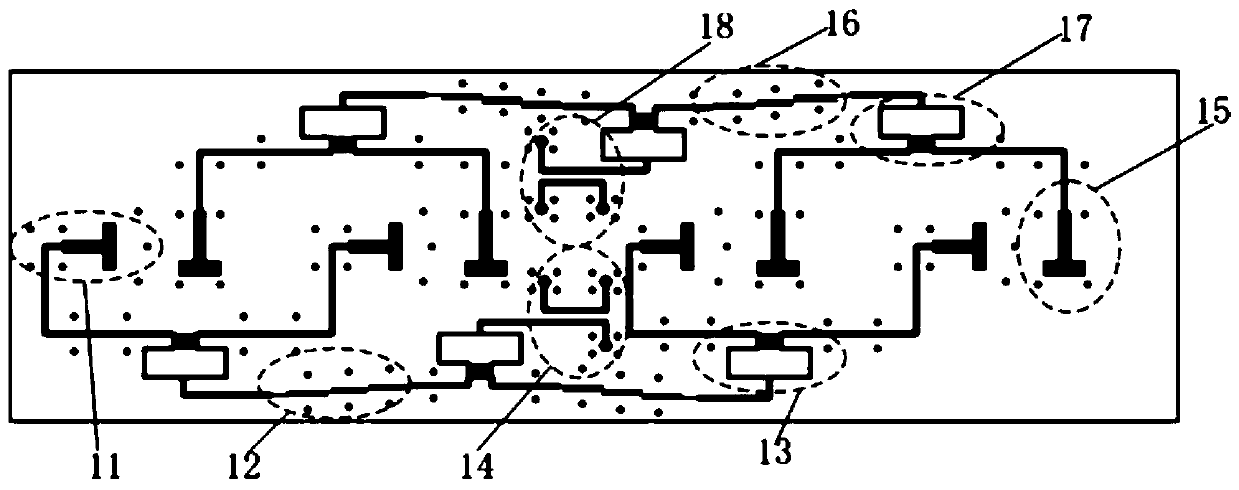

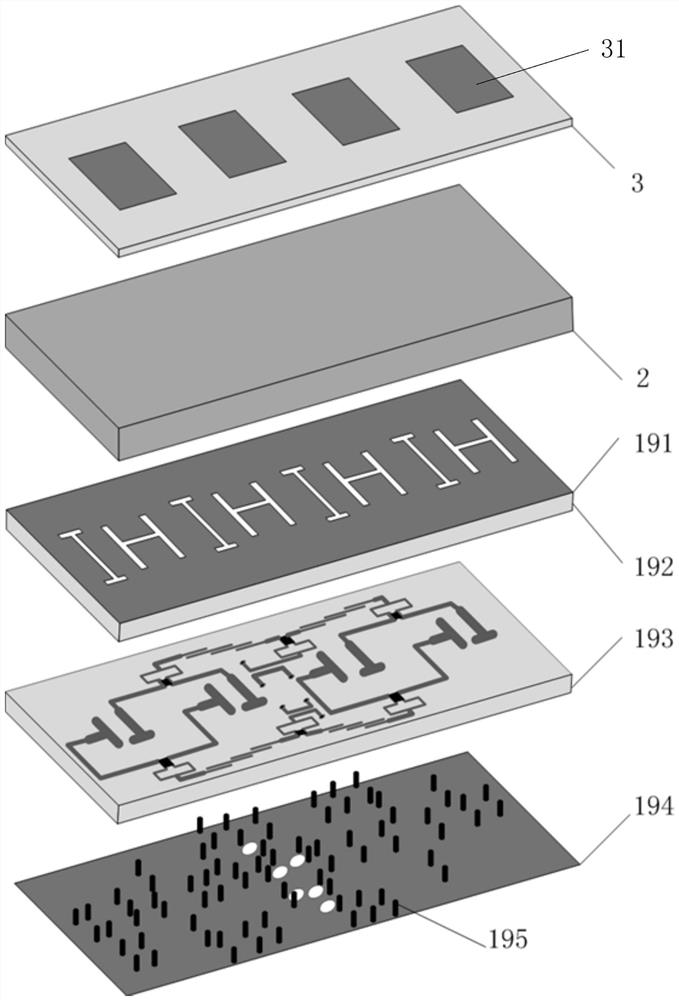

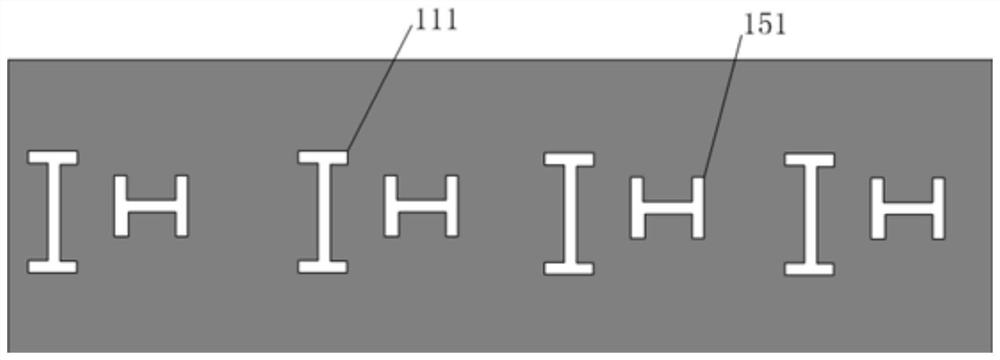

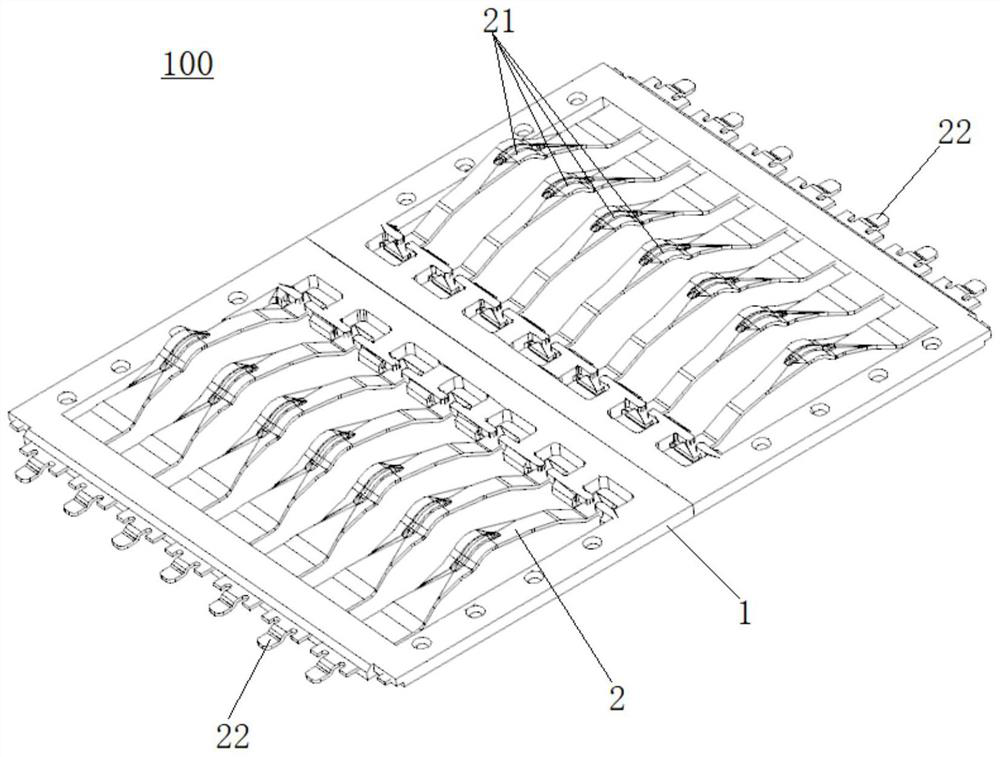

Broadband dual-polarized micro-strip antenna sub-array with filtering and calibration functions

ActiveCN110797649ANo size increaseSuppression of interfering signalsAntenna adaptation in movable bodiesRadiating elements structural formsBroadbandingPerpendicular polarization

The invention discloses a broadband dual-polarized micro-strip antenna sub-array with filtering and calibration functions, which comprises a radiation layer, a paper honeycomb supporting layer and a functional layer. The functional layer comprises an upper printing plate, a lower printing plate and a lower metal surface. An upper metal surface is arranged on the upper surface of the upper printingplate and etched with H-shaped slots, first H-shaped slots are arranged along the vertical direction of the upper metal surface, and second H-shaped slots are arranged along the horizontal direction.A polarization feed network is arranged on the lower printing plate and comprises T-shaped strip lines and characteristic strip lines, the polarization feed network with the T-shaped strip lines perpendicular to the first H-shaped slots is recorded as a horizontal polarization feed network, and the polarization feed network with the T-shaped strip lines perpendicular to the second H-shaped slotsis recorded as a vertical polarization feed network. Metalized via holes are formed in the lower metal surface, penetrate through the lower printing plate and are symmetrically distributed in the twosides of the polarization feed network. Through the technical scheme in the invention, a dual-polarized broadband micro-strip antenna sub-array with power distribution, filtering and calibration functions is realized.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

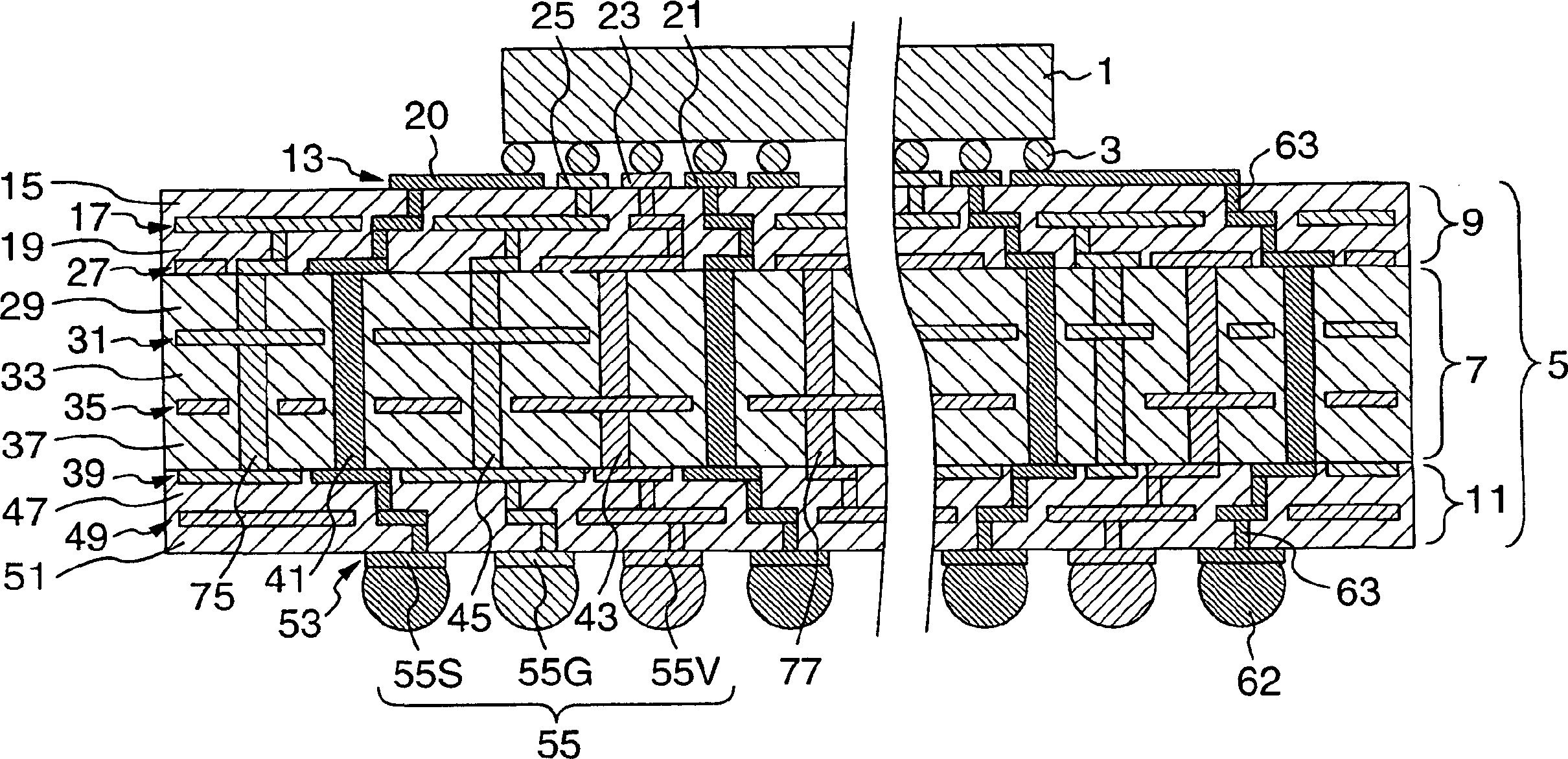

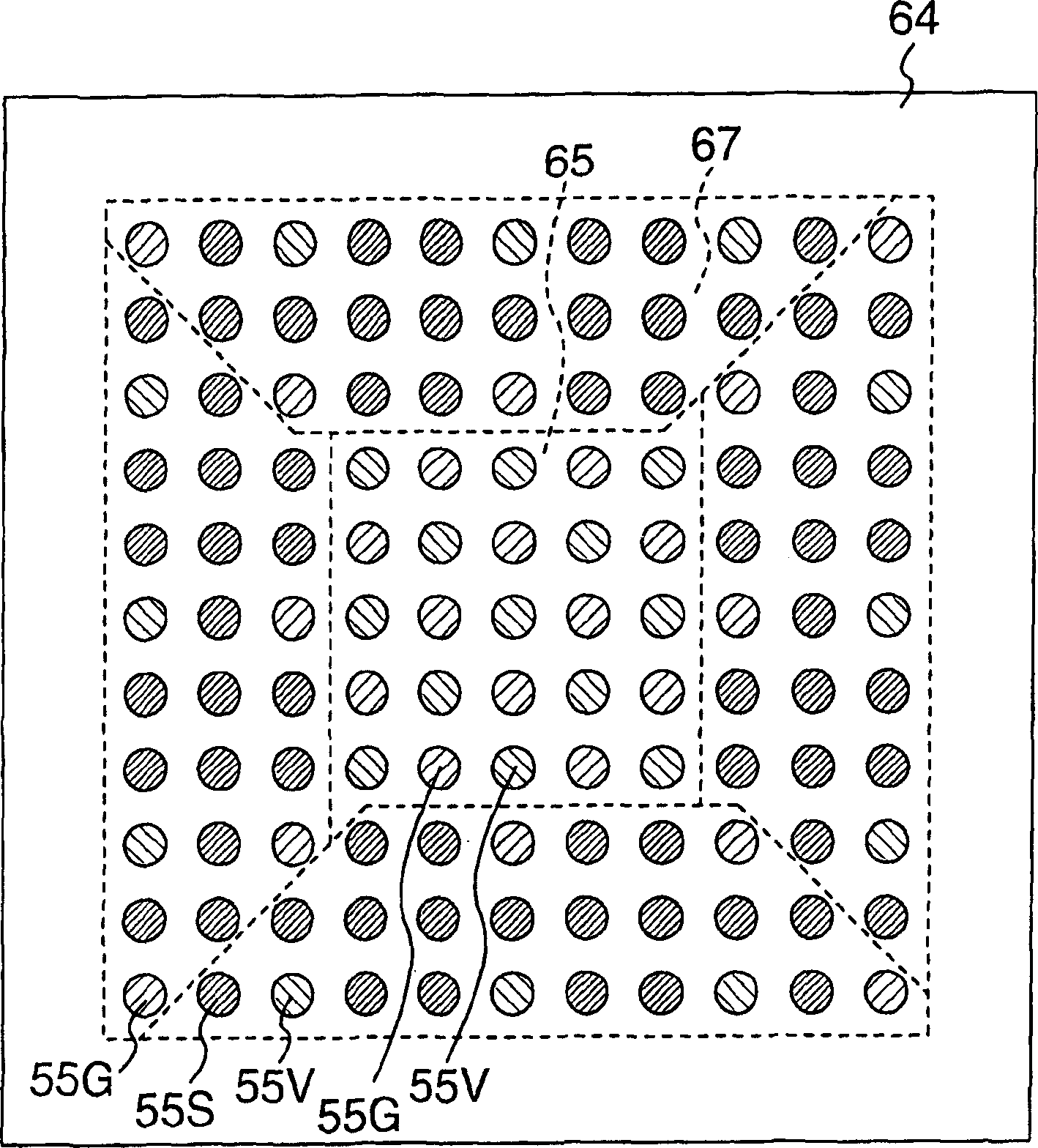

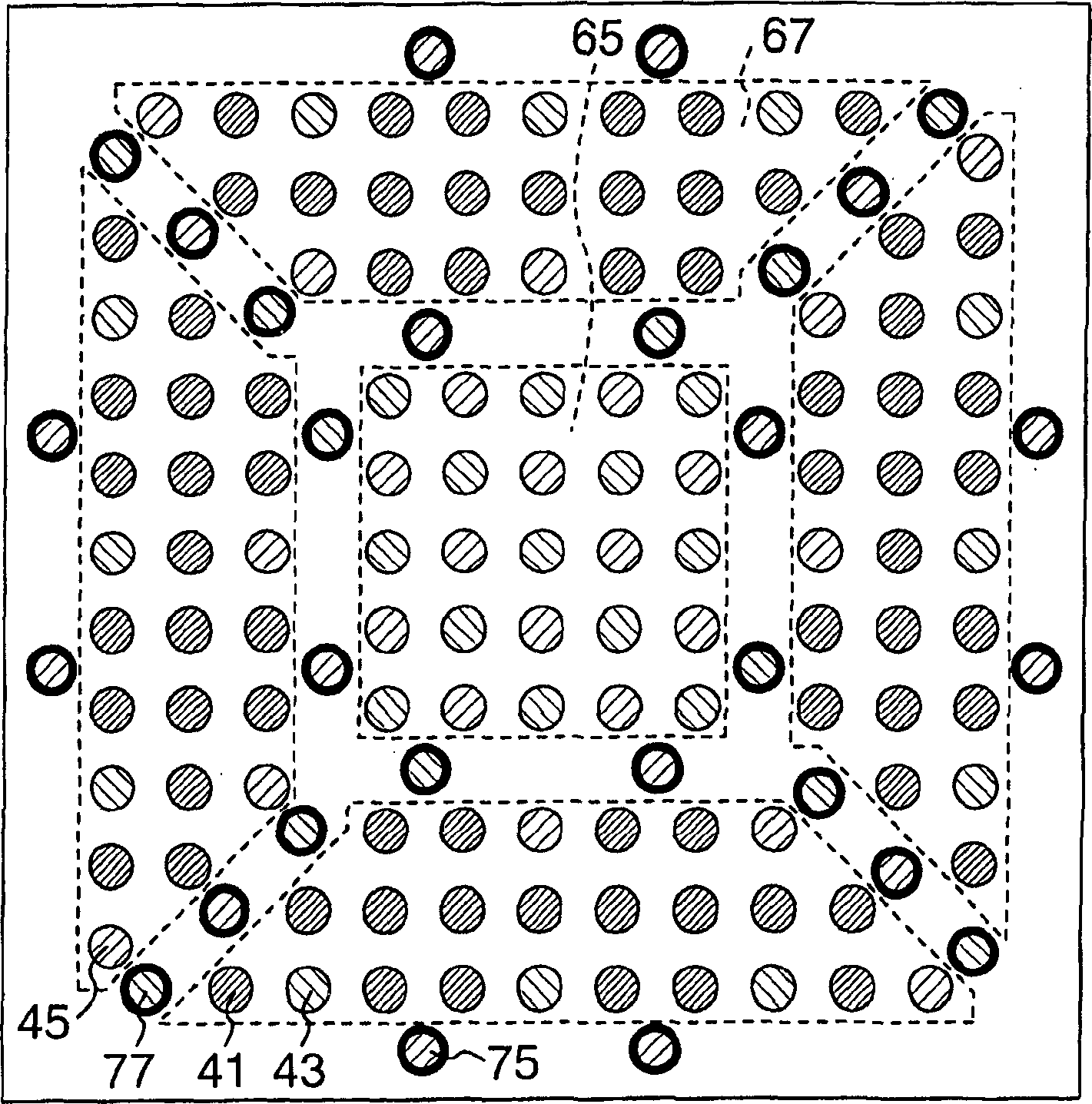

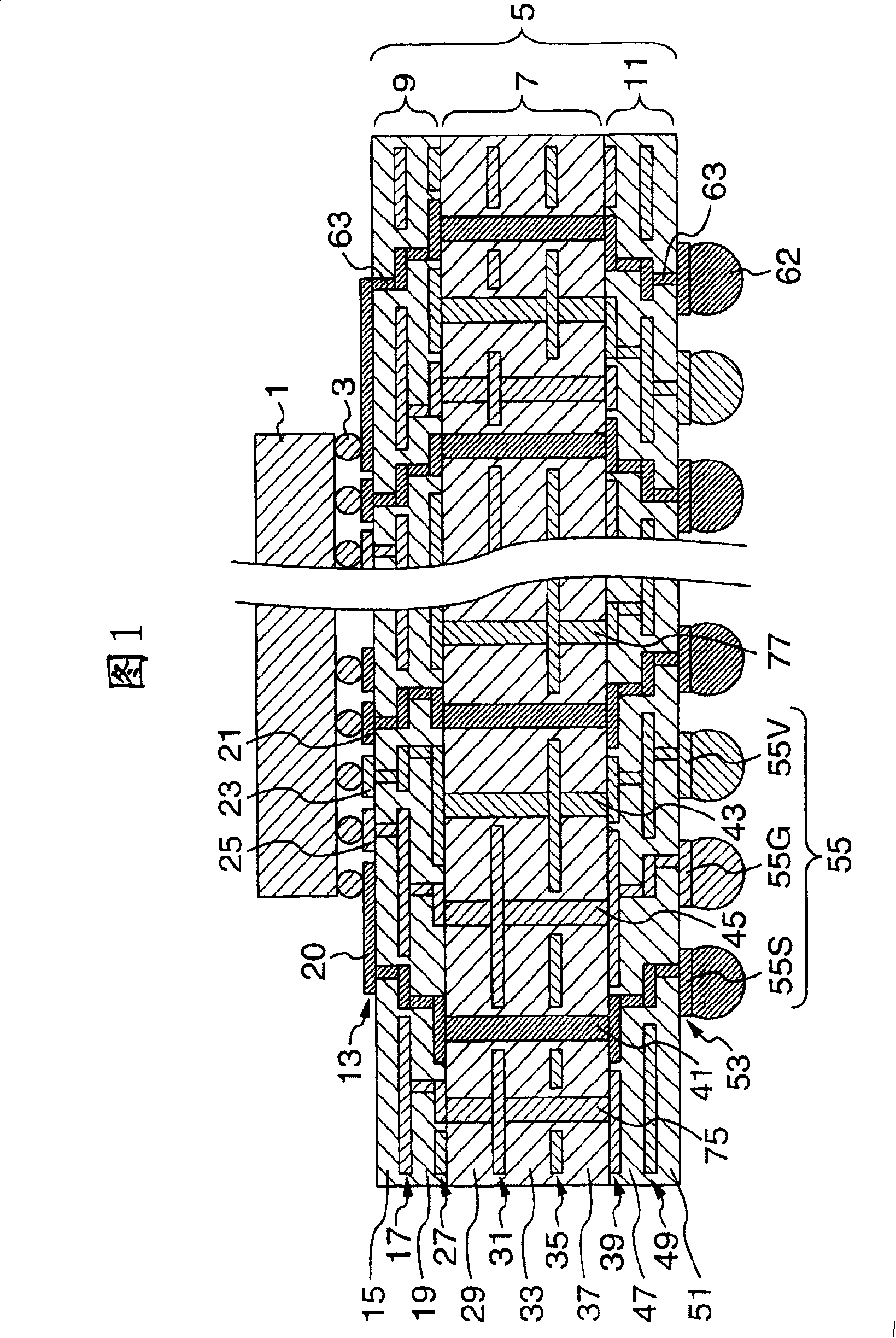

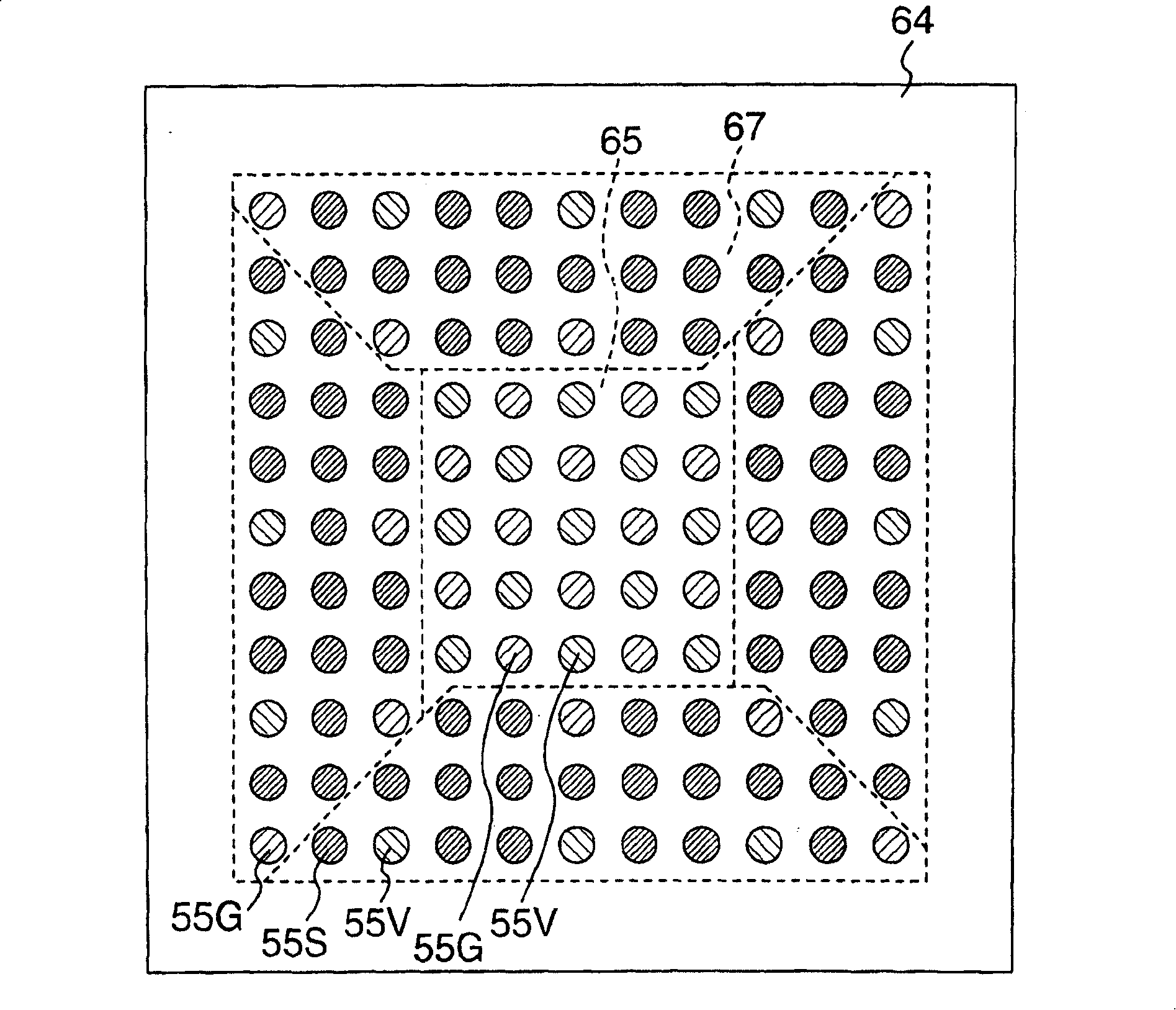

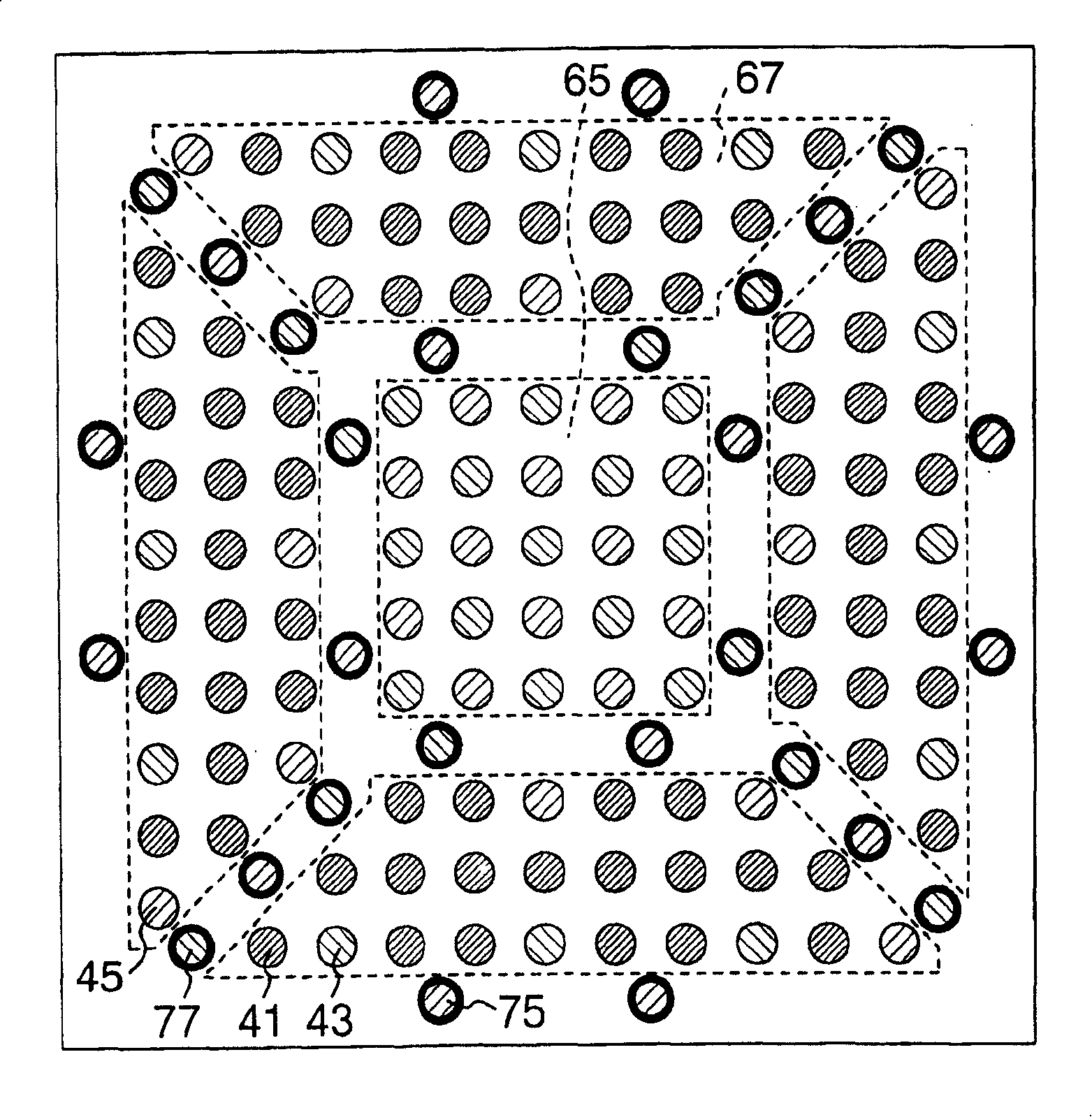

Semiconductor device

InactiveCN1714442AReduce inductanceSmall sizeCross-talk/noise/interference reductionSemiconductor/solid-state device detailsLow noiseDevice material

Owner:HITACHI LTD

Mobile phone spectrometer module and mobile phone spectrometer having the mobile phone spectrometer module

ActiveCN104062007BGood spectral resolutionSimple and square shapeSpectrum investigationGratingImage resolution

The invention is suitable for the technical field of spectrographs, and discloses a mobile phone spectrograph module and a mobile phone spectrograph with the mobile phone spectrograph module. The mobile phone spectrograph module comprises a shell with a slit. A plane-convex collimating lens used for collimating light rays entering the slit is arranged in the shell. A reflecting grating used for reflecting the light rays collimated by the plane-convex collimating lens and changing the incident polychromatic light into monochromatic light emitted in different directions is arranged on one side of the plane-convex collimating lens. A spherical reflecting mirror used for gathering the monochromatic light emitted by the reflecting grating is further arranged in the shell. A biconvex lens is arranged between the spherical reflecting mirror and the receiving face of a mobile phone camera. The mobile phone spectrograph comprises a mobile phone and the mobile phone spectrograph module. The mobile phone spectrograph module and the mobile phone spectrograph with the mobile phone spectrograph module are high in spectral resolution, compact in structure, easy to install and capable of being easily expanded and externally arranged.

Owner:SHENZHEN INST OF ADVANCED TECH

Six-axis robot

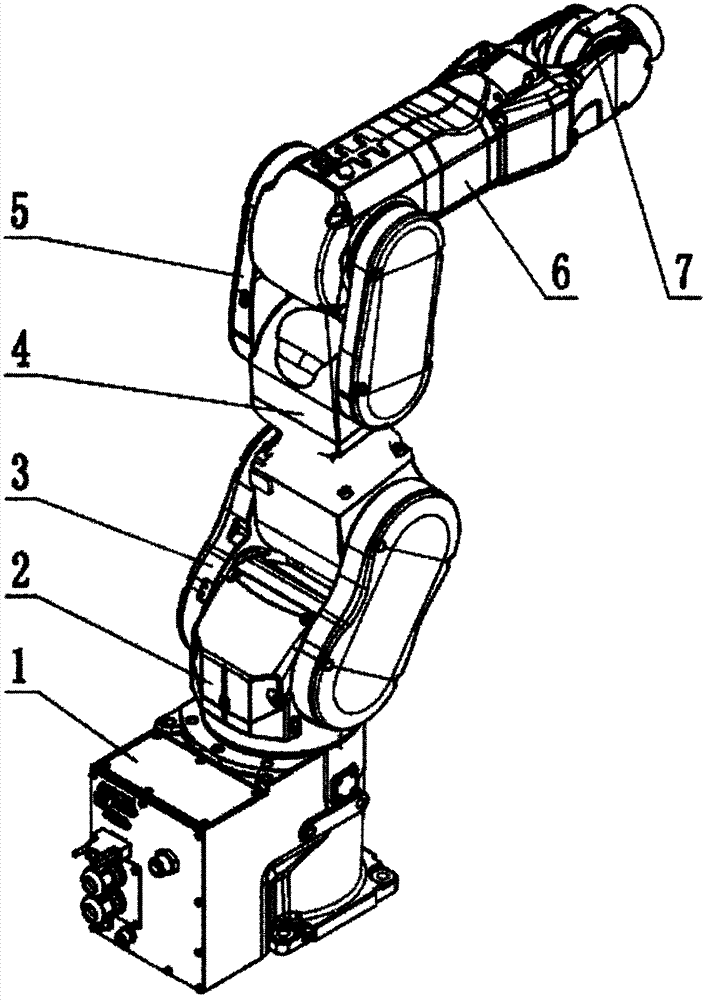

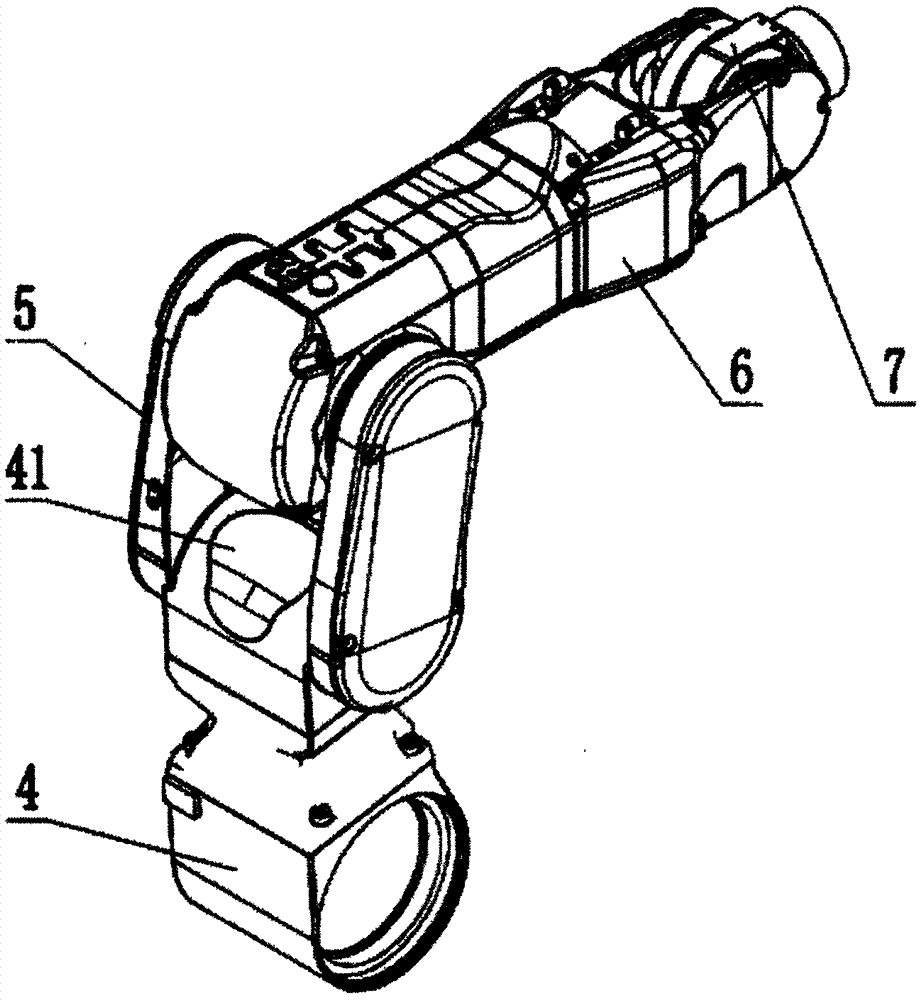

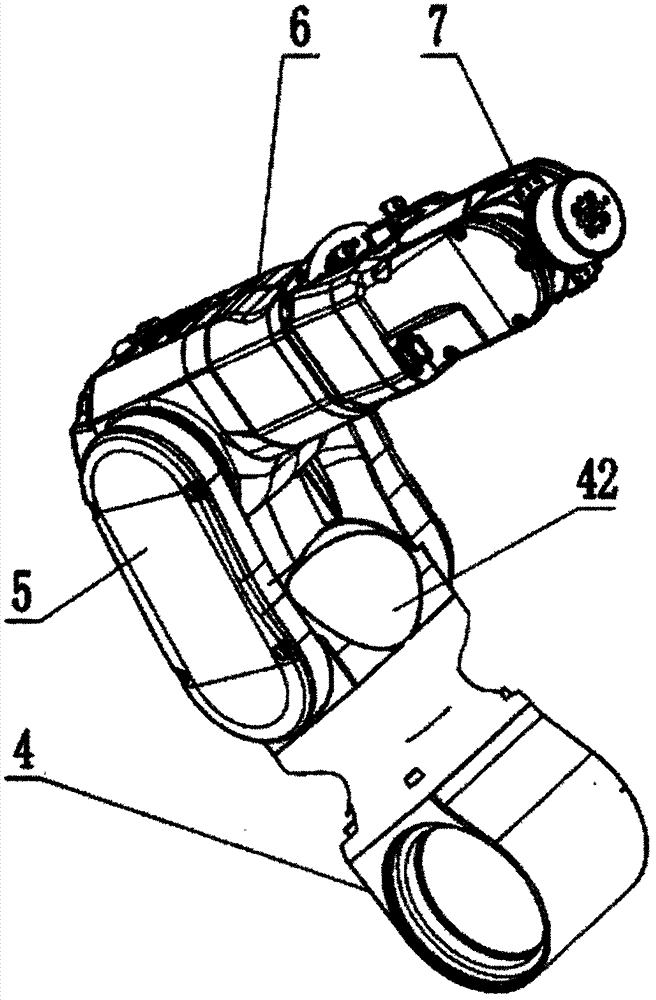

InactiveCN107336225ANo size increaseProgramme-controlled manipulatorJointsTurn angleWorking environment

The invention discloses a six-axis robot, which is used for reducing the overall size of the six-axis robot and enabling the robot to rotate arms flexibly. The six-axis robot is characterized in that an elbow is of a double-joint structure, and a large arm and a small arm are respectively hinged with both ends of the elbow. According to the six-axis robot, on the premise that a rotating shaft is not additionally arranged on the double-joint elbow and the sufficient degree of freedom of the robot is guaranteed, the rotating angle of the six-axis robot on the same plane becomes large, and the overall size of the robot is not increased, so that the six-axis robot is especially suitable for a narrow working environment, and the application range of the six-axis robot is enlarged.

Owner:广东天太机器人有限公司

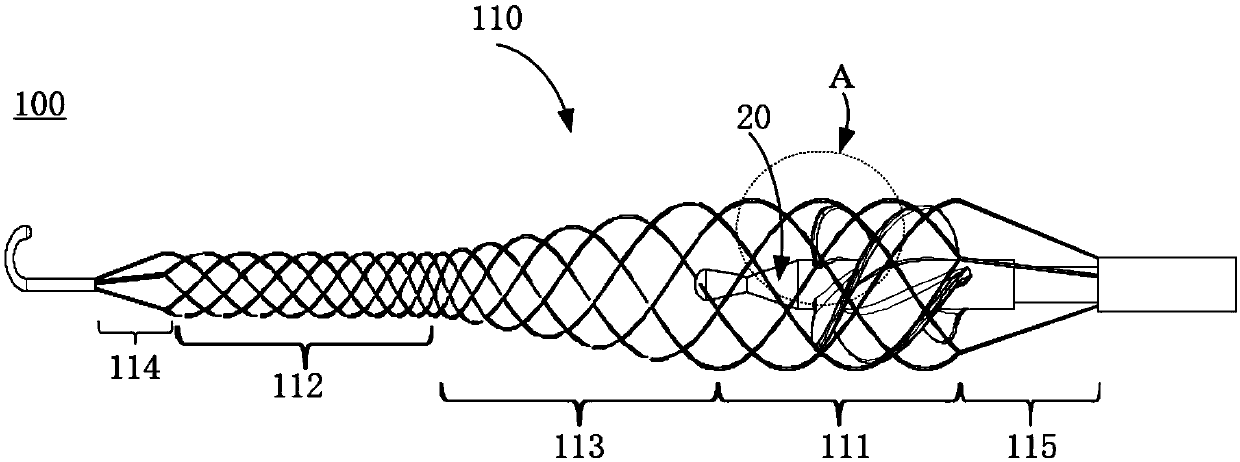

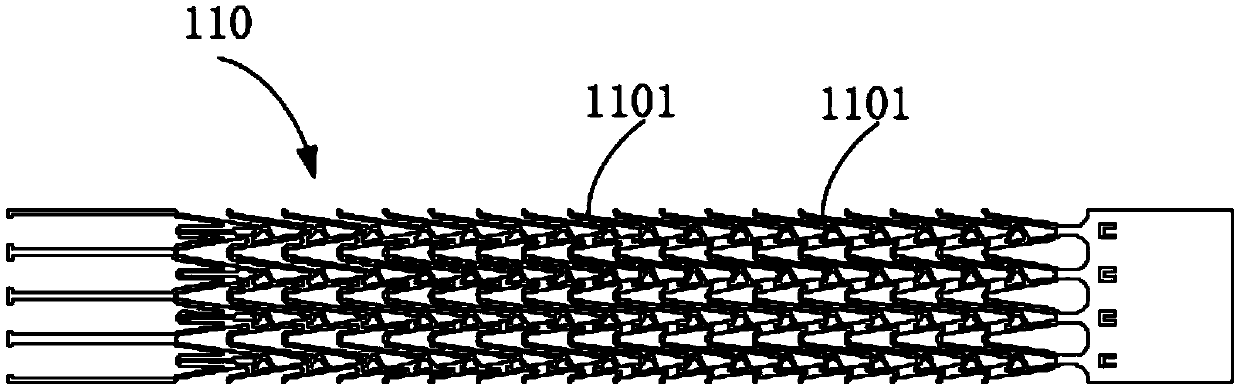

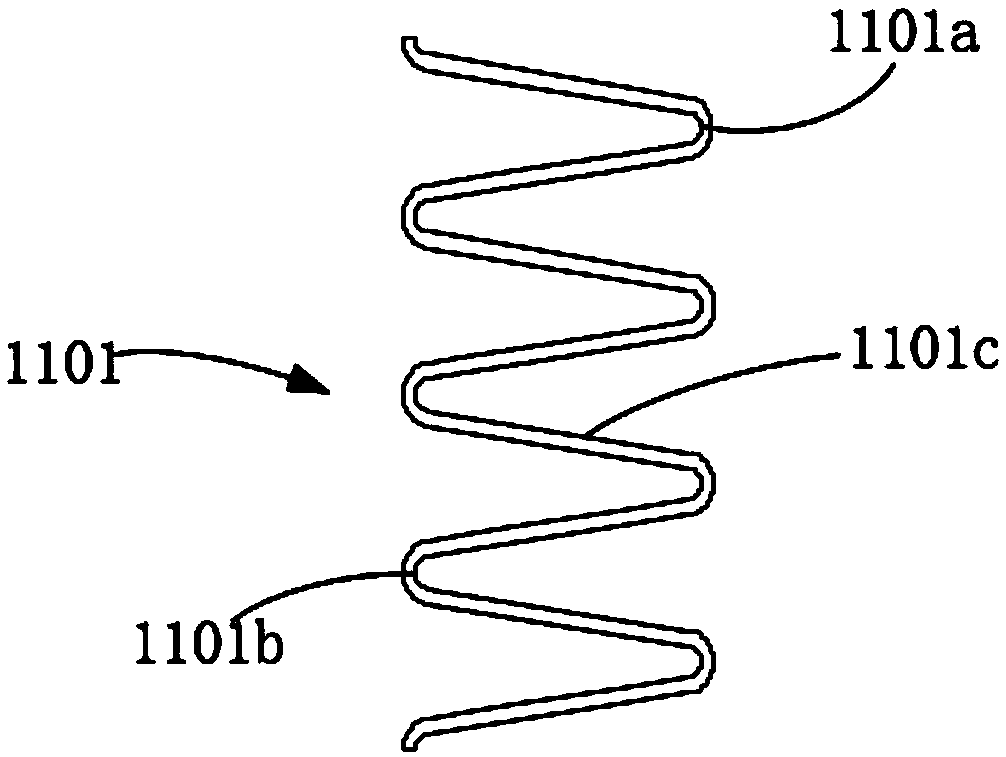

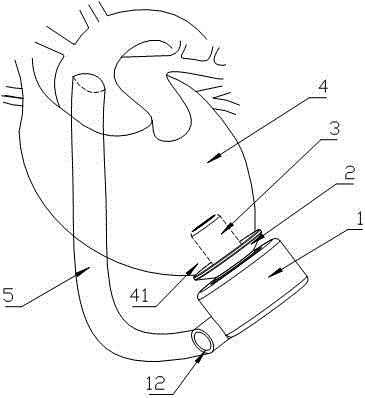

Percutaneous blood pump and mesh basket thereof

InactiveCN111166948AIncrease radial sizeNo need to increase radial dimensionBlood pumpsMedical devicesBlood pumpThrombus

The invention relates to a percutaneous axial blood pump for treating heart diseases and a mesh basket thereof. The mesh basket is mounted on the percutaneous axial blood pump. The mesh basket comprises an expandable tube; the expandable tube comprises an impeller area and a far end area; the far end area is fixedly connected with the impeller area; the impeller area and the far end area are arranged along the axial direction of the expandable tube; the impeller area is used for accommodating the impeller of the percutaneous axial blood pump, and the pipe diameter of the impeller area is larger than the pipe diameter of the far end area; and the impeller area of the expandable tube is positioned in an aorta and the far end area of the expandable tube is positioned in a left ventricle. As the pipe diameter of the impeller area of the expandable tube is larger than the pipe diameter of the distal end area of the expandable tube, the expandable tube does not easily move from the aorta tothe left ventricle. As the pipe diameter of the impeller area is large, the radial size of the impeller can be increased, so that the rotating speed of the impeller can be reduced on the premise of ensuring an auxiliary flow of 5L / min, the heating phenomenon of transmission parts such as bearings, rotating shafts and the like can be reduced, and a thrombus phenomenon caused by heating of the partscan be reduced.

Owner:CARDIOPOWER MEDTECH SHANGHAI CO LTD

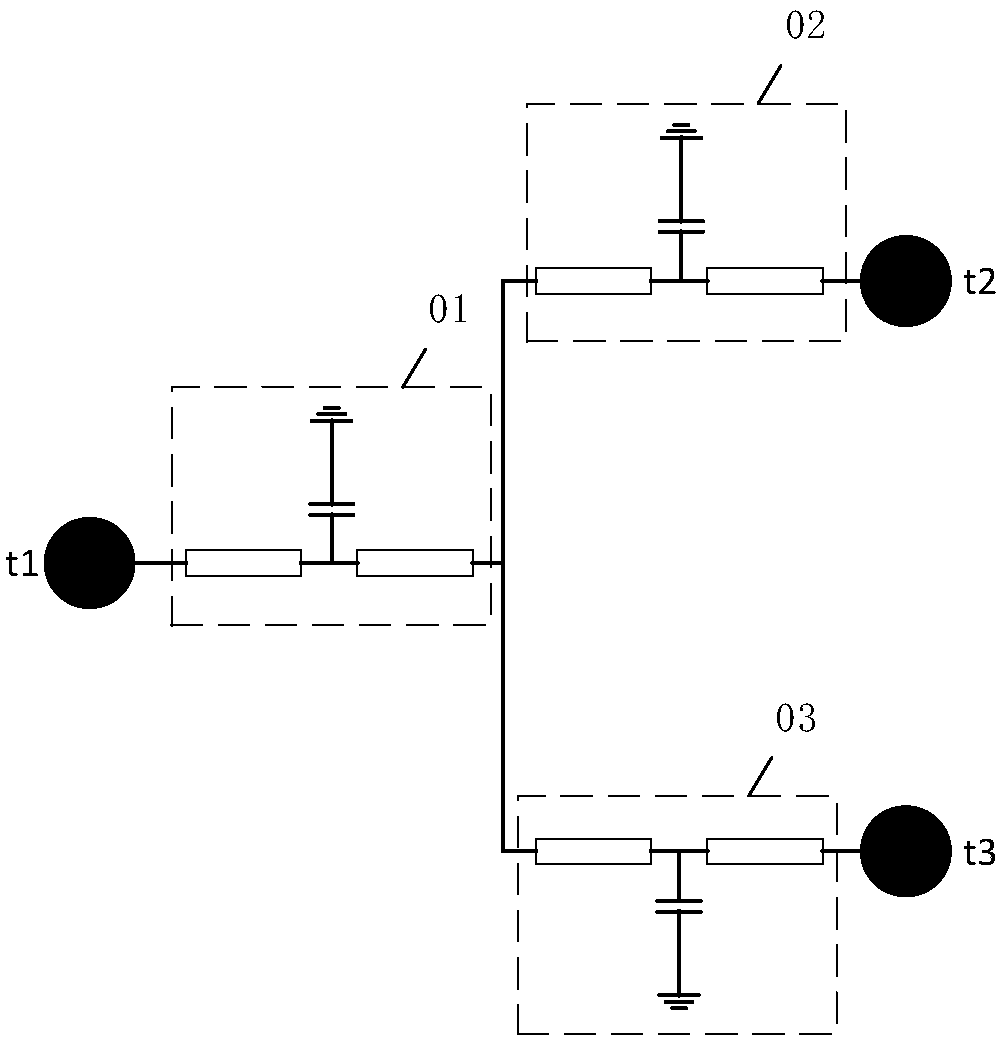

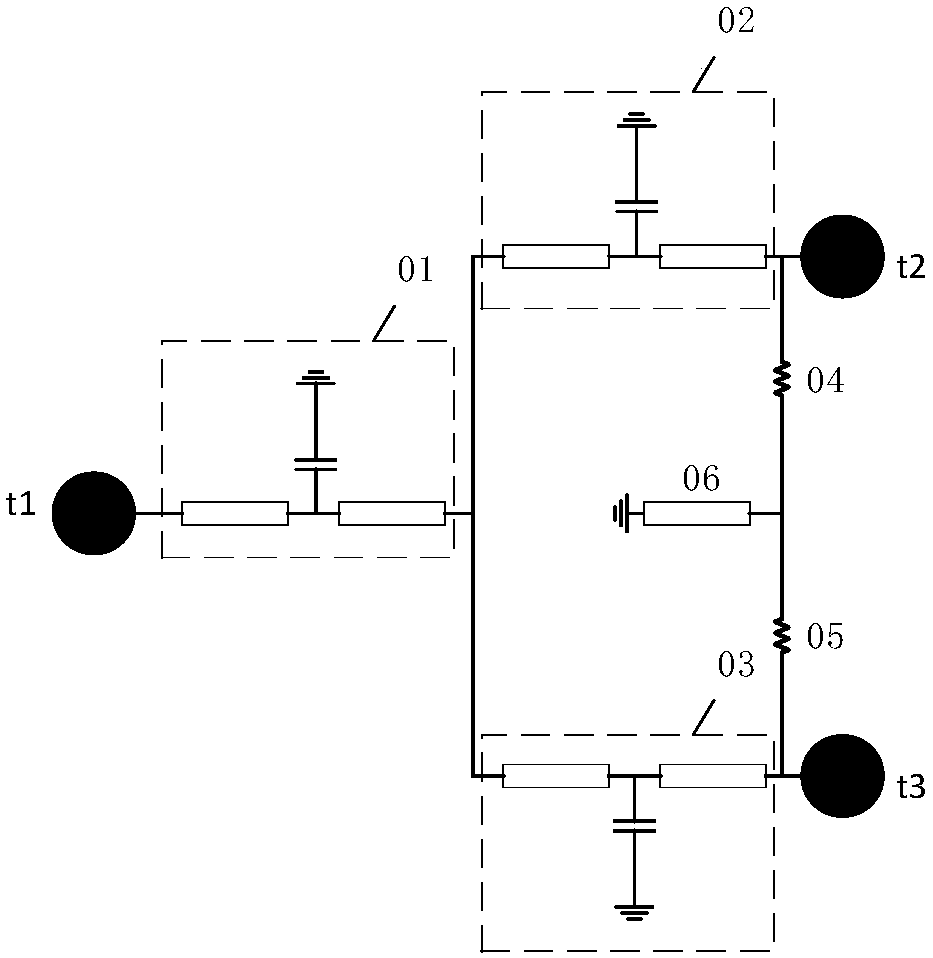

Millimeter wave power amplifier

ActiveCN110277965ANo size increaseReduce lossPower amplifiersAmplifier input/output impedence modificationAudio power amplifierResistor

The invention discloses a millimeter wave power amplifier which comprises a signal input end, a signal output end, a power matching unit, a power distribution and synthesis matching unit and a power amplification unit, and the power distribution and synthesis matching unit further comprises a first resistor, a second resistor and a grounding transmission line. In the power distribution synthesis matching unit, the first end of a first resistor and the first end of a second resistor are connected with the first end of a grounding transmission line, the second end of the grounding transmission line is grounded, the second end of the first resistor is connected with the second end of a second T-shaped structure, and the second end of the second resistor is connected with the second end of a third T-shaped structure. Based on the prior art, the bandwidth is broadened by adding components on the circuit, the isolation degree of signals between branches is improved by adding the first resistor and the second resistor while the size of the circuit is not increased, and the circuit loss is reduced. The millimeter wave power amplifier chip can be realized in multiple processes, and huge benefits are brought to design and manufacturing of the millimeter wave power amplifier chip.

Owner:KUNSHAN BRANCH INST OF MICROELECTRONICS OF CHINESE ACADEMY OF SCI

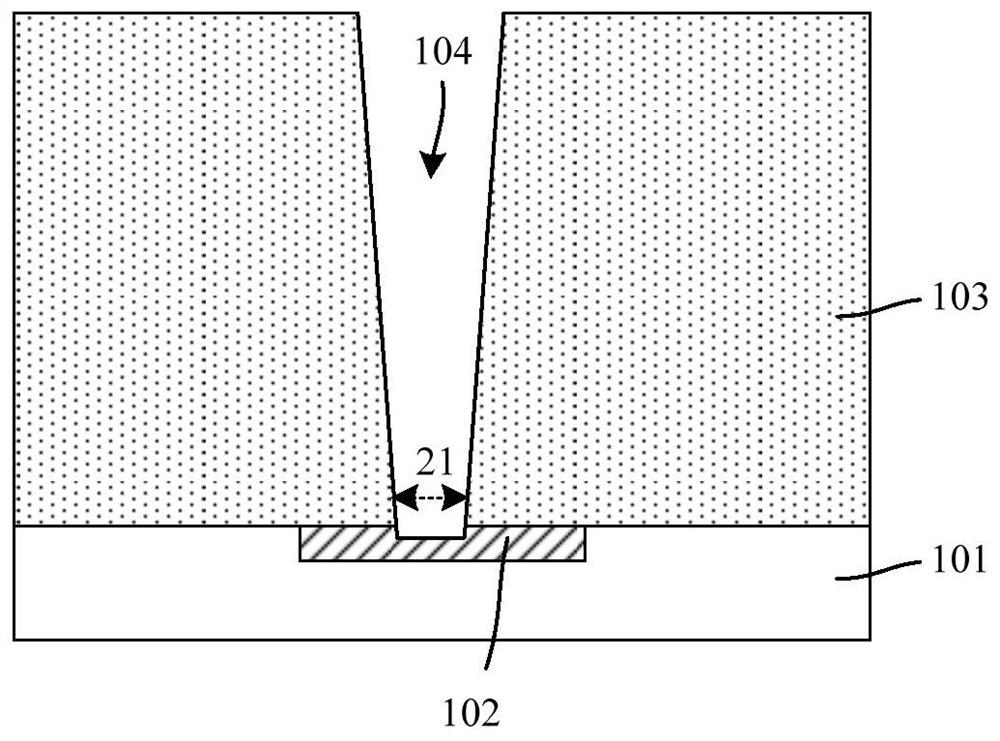

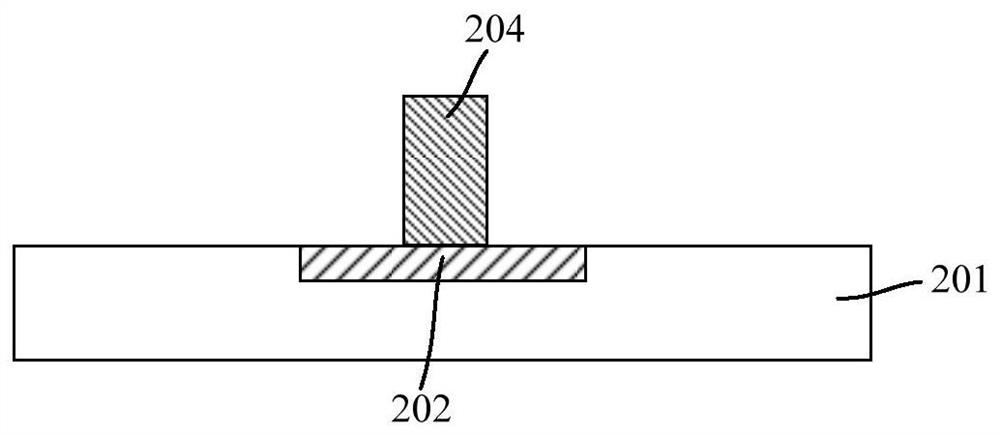

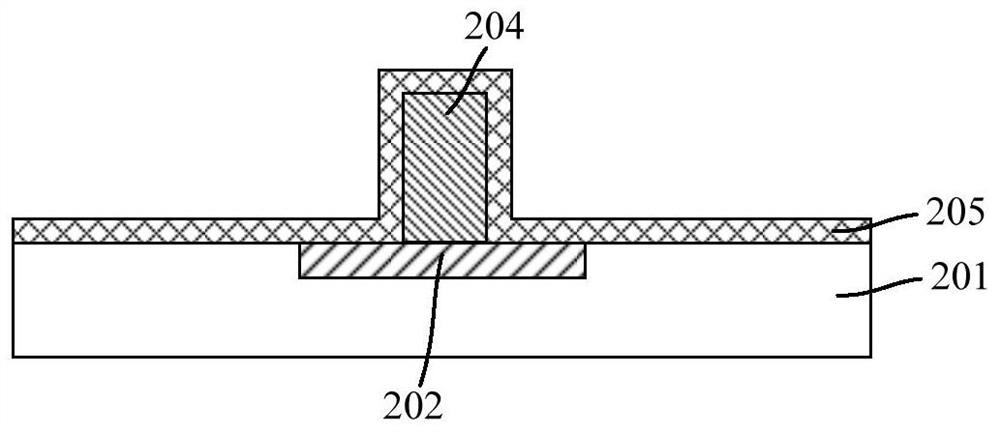

Contact window structure, metal plug and forming method thereof, and semiconductor structure

PendingCN114256136AIncrease contact areaReduce contact resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDielectric layer

The invention discloses a contact window structure, a metal plug and a forming method thereof, the forming method of the contact window structure and a semiconductor structure, an annular gasket is formed on the surface of a target layer, and the middle of the annular gasket is provided with a central through hole exposing part of the surface of the target layer; forming a dielectric layer covering the substrate, the target layer and the annular gasket; etching the dielectric layer, and forming an etching hole communicated with the central through hole in the dielectric layer; and the annular gasket is removed along the etching hole and the central through hole, so that the size of the central through hole is enlarged, and the etching hole and the central through hole with the enlarged size form a contact window structure. Through the formed annular gasket, when the contact window structure is formed and the annular gasket is removed, the size of the central through hole can be increased, so that the size of the bottom of the contact window structure can be increased, and when a metal plug is formed in the contact window structure, the contact area between the bottom of the metal plug and a target layer is increased; and the contact resistance between the two is reduced.

Owner:CHANGXIN MEMORY TECH INC

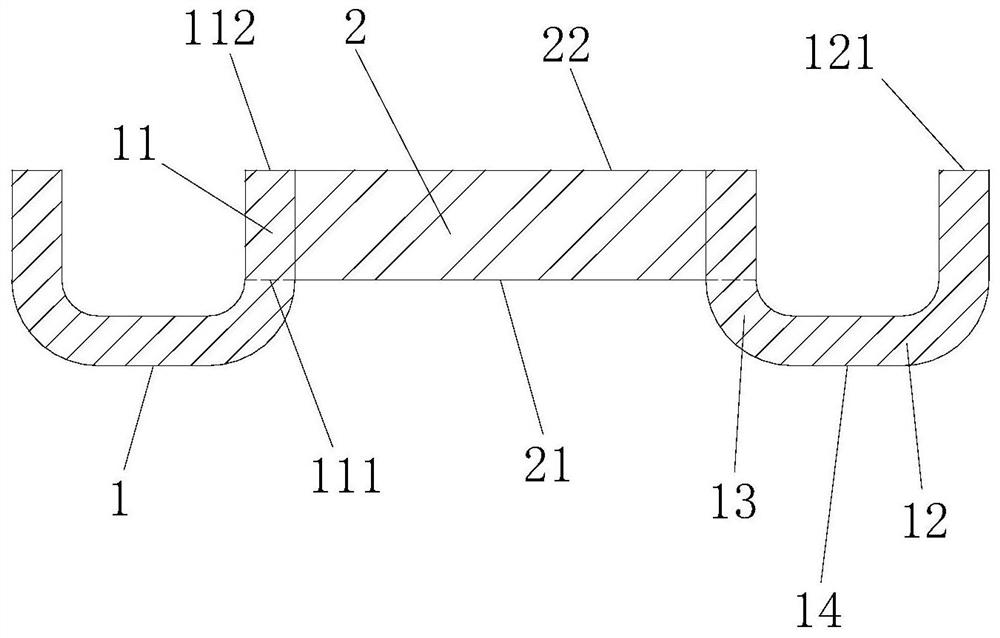

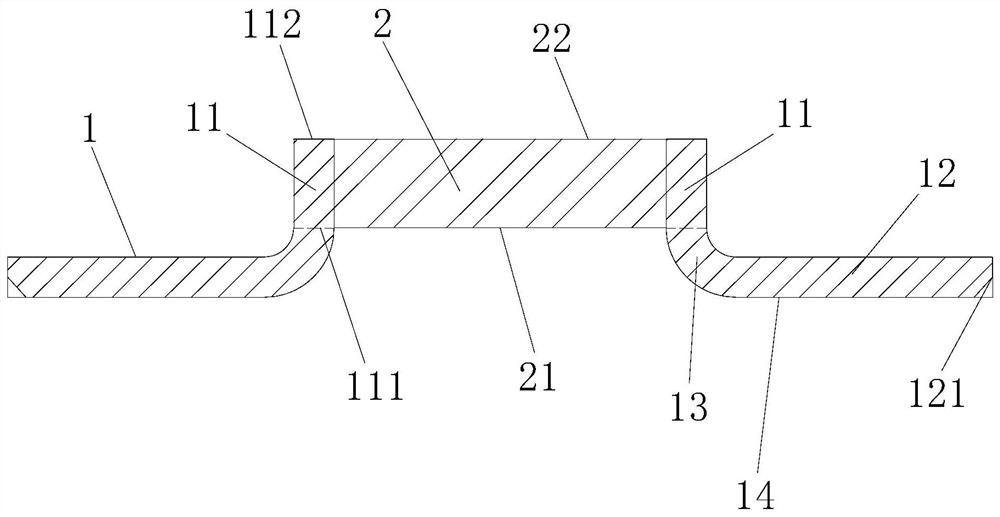

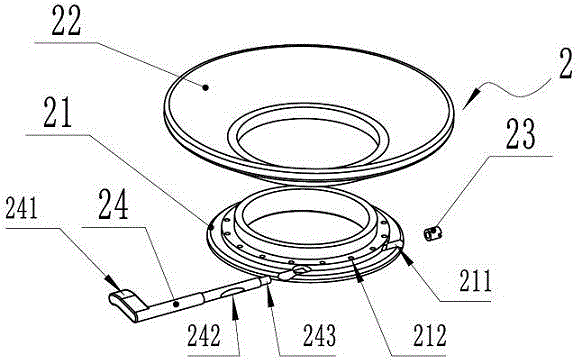

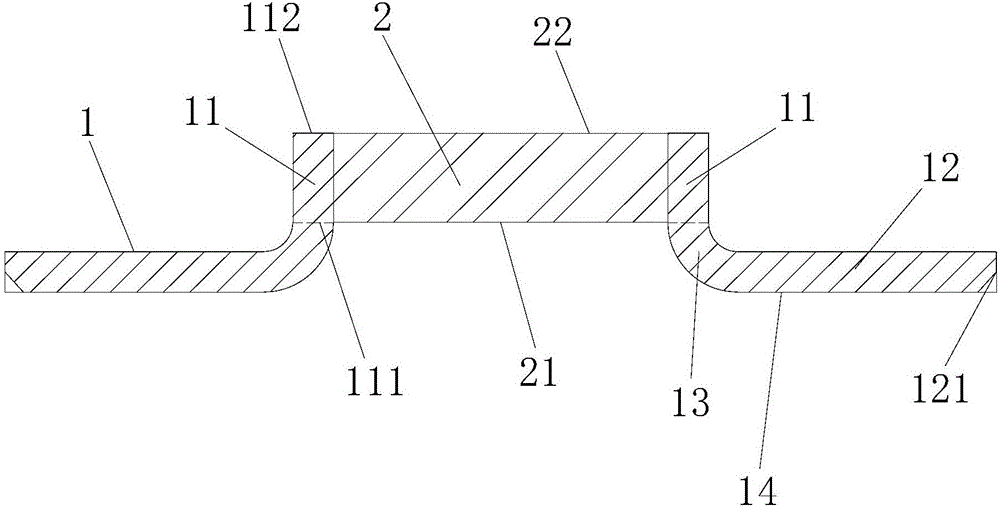

An optical transmission window for atomic clocks

ActiveCN106707725BReduce the chance of damageImprove yieldApparatus using atomic clocksMountingsEngineeringOptic lens

The invention discloses an optical transmission window for an atomic clock. The optical transmission window includes a sleeve and an optical lens set in the sleeve; a cylindrical wall of the sleeve includes a vertical side wall; The bottom end of the vertical side wall portion is an extension portion extending outward along the circumference of the bottom end of the vertical side wall portion; the circumferential side wall surface of the optical lens and the vertical side wall of the cylindrical body wall The inner side wall surface of the part is sealed and fixed; the bottom surface of the optical lens is flush with the bottom edge of the vertical side wall part in the barrel wall. By improving the structure of the optical transmission window, the invention is suitable for the batch coating of the optical transmission window, and solves the problem that the traditional optical transmission window cannot be used for multiple optical transmission windows at one time due to the limitation of its structure by the existing coating machine. The problem of batch coating of optical lenses in .

Owner:NO 12 RES INST OF CETC

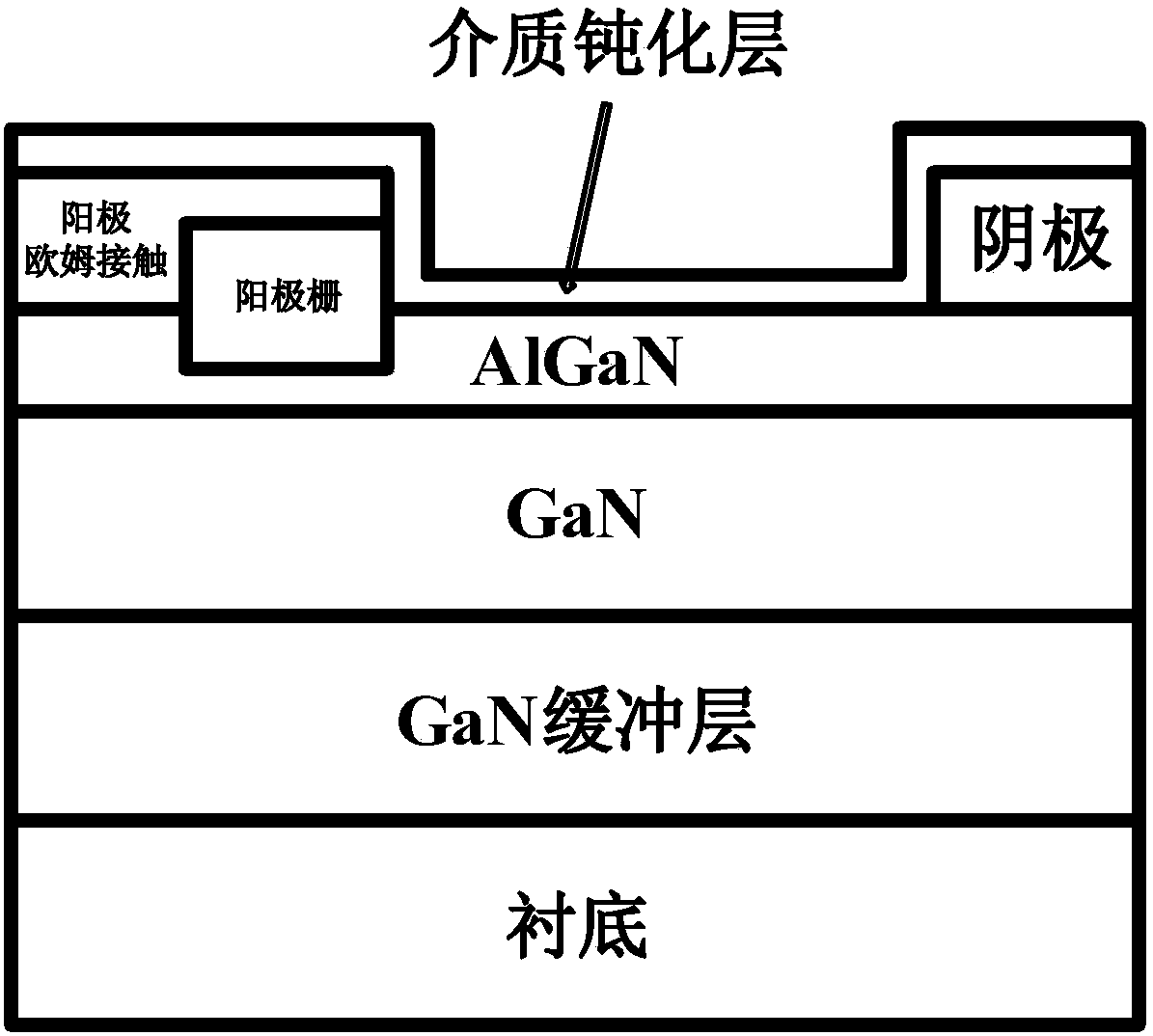

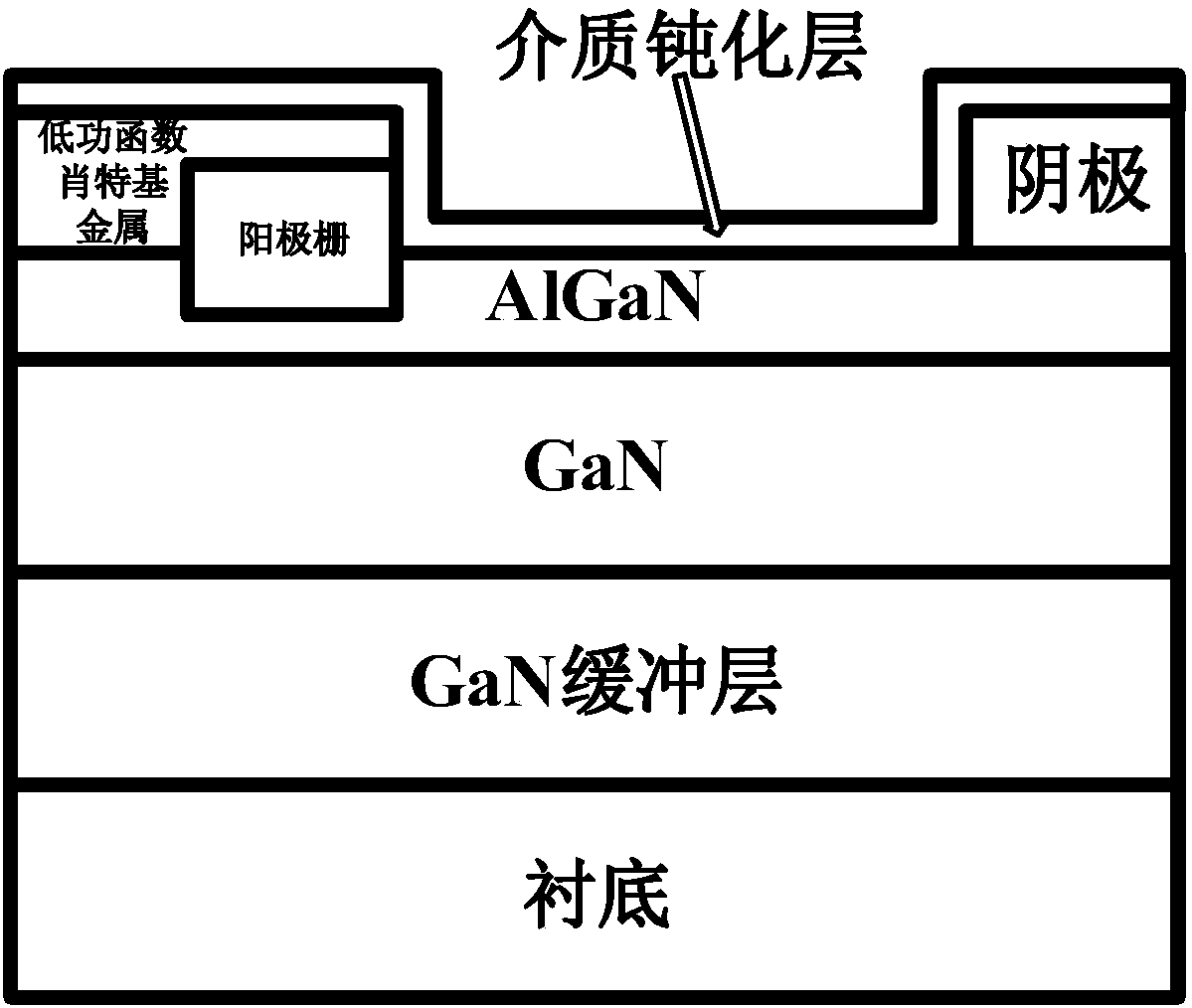

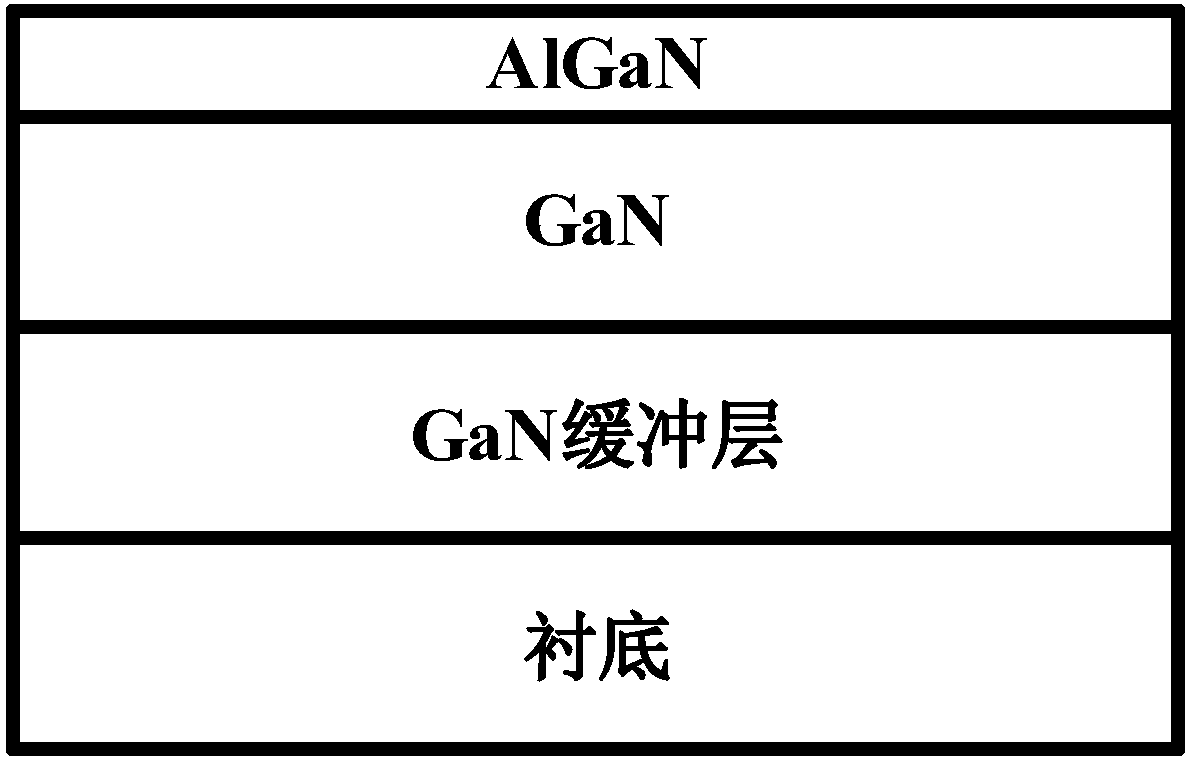

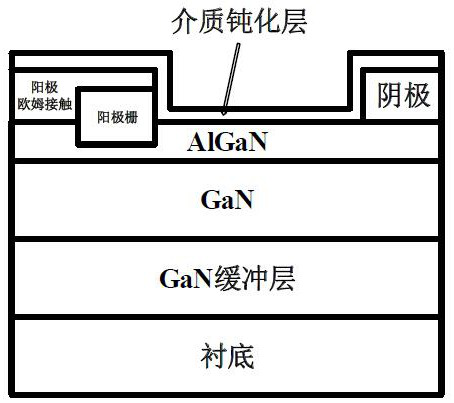

Device structure and implementation method for improving GaN L-FER reverse breakdown voltage

ActiveCN108666360AEliminate leakage current injectionImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionOhmic contact

The invention discloses a device structure for improving a GaN L-FER reverse breakdown voltage and a fabrication method thereof. The structure includes a substrate, a GaN or AlN buffer layer, an intrinsic GaN channel layer, and an intrinsic AlGaN barrier layer, dielectric passivation layer, anode double Schottky contact, and cathode ohmic contact. The AlGaN / GaN heterojunction material is epitaxially grown on the substrate, and after the ohmic contact and planar isolation are formed on the structure, the anode structure of the double Schottky contact is further formed, and finally the passivation layer is deposited to achieve passivation of the device. The device structure utilizes the anode structure of the double Schottky contact, and the Schottky contact plays a certain shielding effecton the high voltage in the reverse breakdown process, Thereby reducing the leakage current injected from the anode through the channel barrier layer or the buffer layer of the device to the cathode, further increasing the reverse breakdown voltage of the device. The implementation method is simple and can greatly improve the reverse breakdown voltage of GaN L-FER, thereby broadening its application in the field of power electronics.

Owner:PEKING UNIV

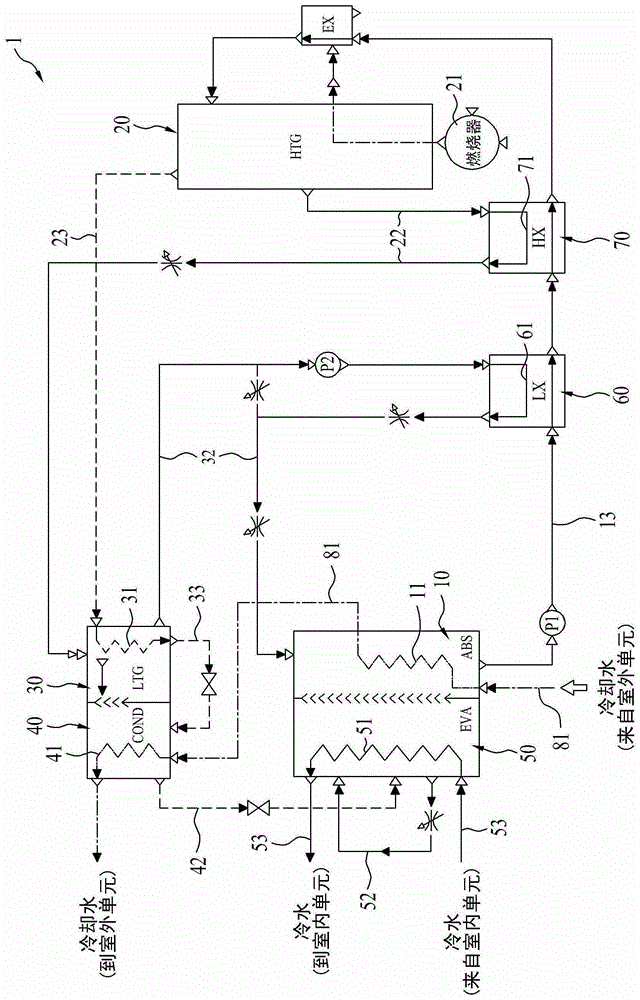

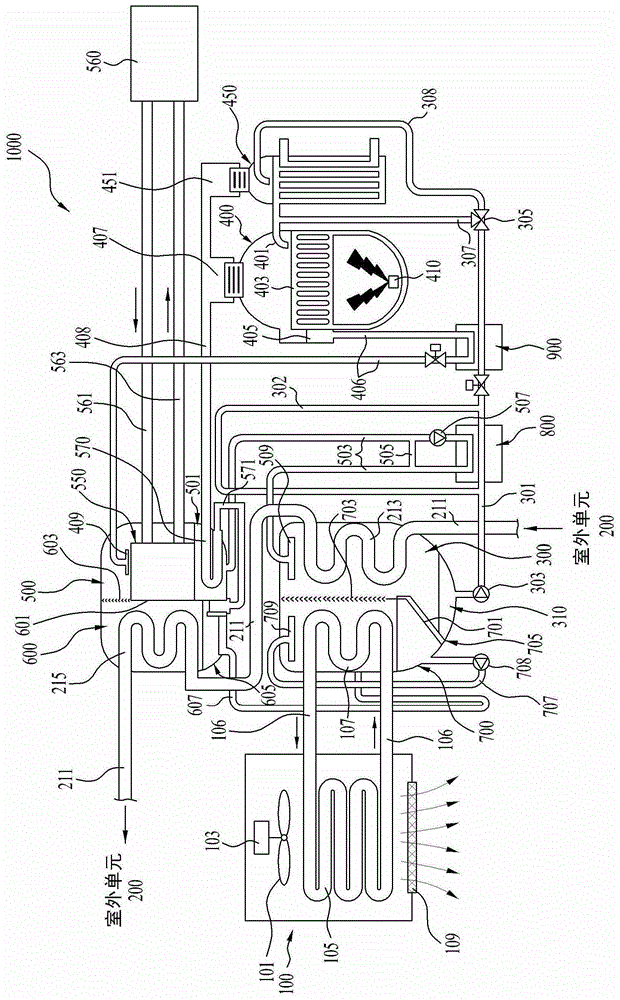

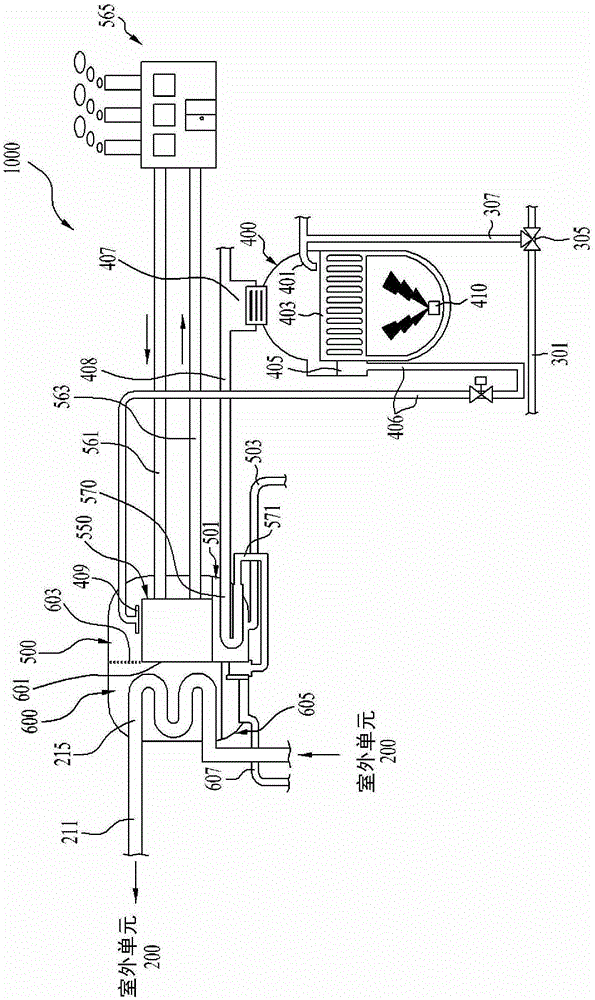

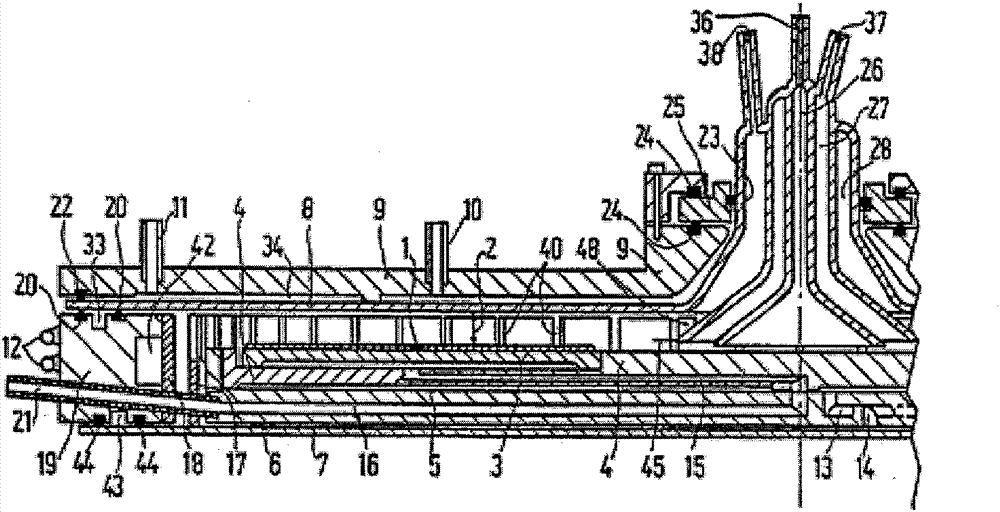

Low temperature generator and absorption cold and hot water machine including the low temperature generator

ActiveCN103245131BReduce consumptionReduce the amount of fuelBoilers/analysersClimate change adaptationEngineeringRefrigerant

PURPOSE: A low temperature generator and an absorption type chiller-heater with the same are provided to have a simple pipe structure because an additional shell for using an auxiliary heat source is not necessary by installing an auxiliary heat source generator in a low temperature generator arranged in a shell of a condenser. CONSTITUTION: An absorption type chiller-heater comprises a high temperature generator (400), a low temperature generator (500), and a condenser (600). The high temperature generator heats dilute solution receiving from an absorber (300) so that the dilute solution can be separated to refrigerant vapor and intermediate solution. The low temperature generator separates the intermediate solution received through an intermediate solution pipe (406) to refrigerant vapor and rich solution using the heat energy of the refrigerant vapor separated by the high temperature generator. The condenser is arranged in one side of the lower temperature generator and condenses the refrigerant vapor separated by the low temperature generator to the liquid-phase refrigerant. [Reference numerals] (200) Outdoor unit

Owner:LG ELECTRONICS INC

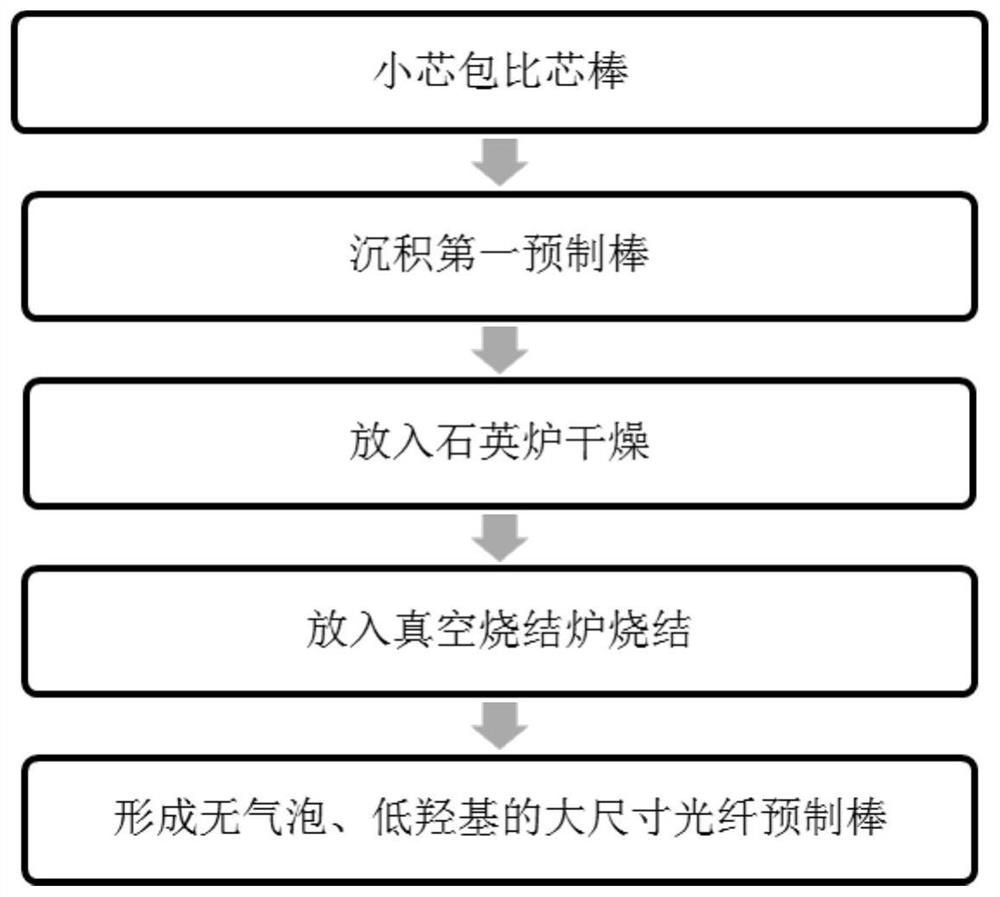

Manufacturing method of large-size optical fiber preform

PendingCN113620589ASave capacity and costReduce equipment loadGlass making apparatusHoley fiberCore (optical fiber)

The invention discloses a manufacturing method of a large-size optical fiber preform. The manufacturing method comprises the following steps: depositing by using a core rod with a small core-to-package ratio as a target rod, drying in a quartz furnace to increase the density of the porous optical fiber preform, introducing a small amount of chlorine gas and inert gas in the drying process, controlling the flow rate of the chlorine gas to be 0.3-0.8 L / min and the flow rate of the inert gas to be 5-10 L / min, and finally, putting into a vacuum sintering furnace, and sintering and densifying to form the final large-size optical fiber preform. According to the invention, the load of the vacuum sintering furnace can be reduced, the bubble-free, large-size and low-hydroxyl optical fiber preform can be manufactured, the overall manufacturing cost is low, and the method is suitable for large-scale production.

Owner:杭州金星通光纤科技有限公司

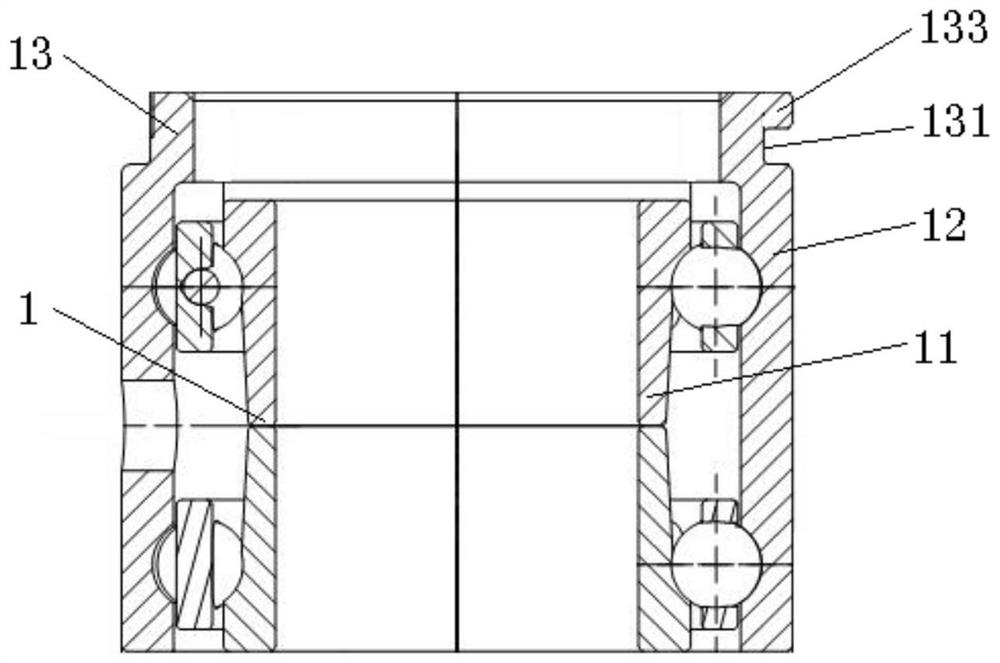

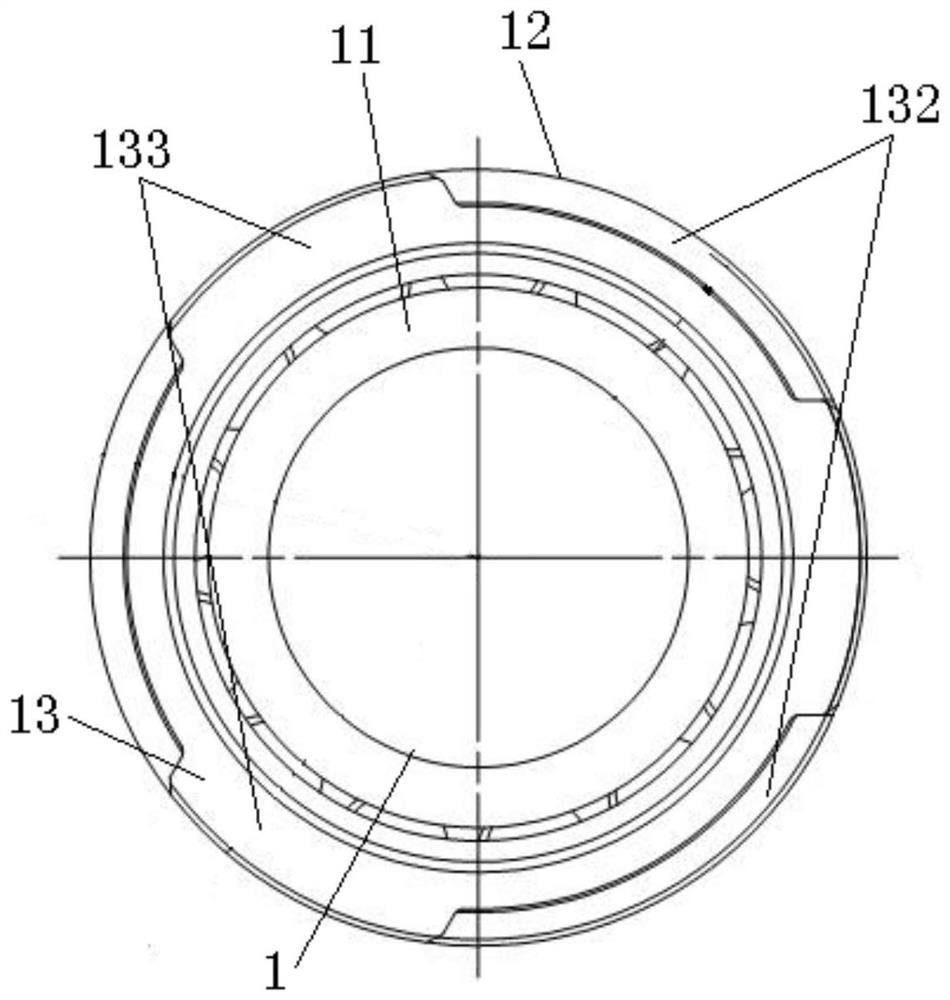

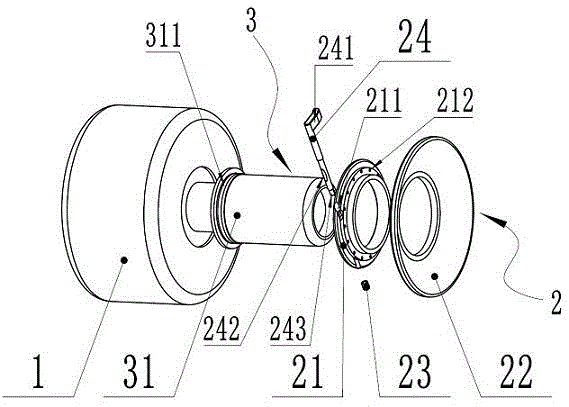

Installation device and assembly method of transmission components

ActiveCN112161038BWeight increaseAxial positioning preventsGearing detailsBearing unit rigid supportStructural engineeringMechanical engineering

The invention discloses an installation device and an assembly method of a transmission assembly. The installation device includes a bearing, the inner ring of the bearing is connected with the transmission assembly, the outer ring of the bearing is fixed on the installation surface of the case, and the case is provided with a The casing hole, the mounting surface of the casing is located on the outside of the casing, the outer ring of the bearing is extended axially to form a mounting ring for extending from the casing through the casing hole to the outside of the casing, the outer diameter of the mounting ring Less than or equal to the outer diameter of the outer ring, the outer wall surface of the installation ring is provided with an axial positioning groove along the circumference, and the end surface of the installation ring is provided with a circumferential positioning block. The outer ring is fixed with a fixed anti-rotation mechanism. The fixed anti-rotation mechanism is inserted into the axial positioning groove, and the mounting ring is pressed axially and then fixed on the mounting surface, so as to realize the axial positioning of the bearing. At the same time, the fixed anti-rotation mechanism and The circumferential positioning blocks are matched to prevent the outer ring of the bearing from rotating in the circumferential direction.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

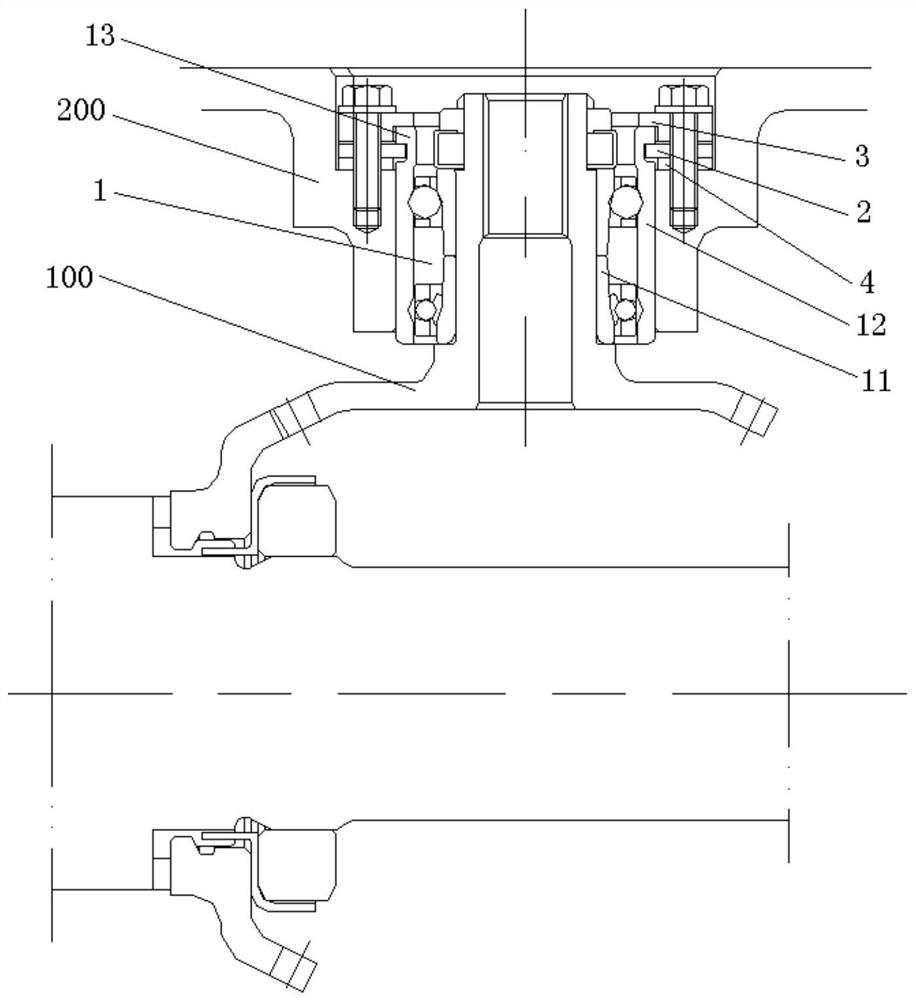

A ventricular connection component

The invention provides a heart ventricle connection assembly which comprises a suture ring assembly and a blood pump connection assembly. The suture ring assembly not only comprises a suture ring and a suture ring seat, but also comprises a connection hinge pin; the connection hinge pin passes through a through hole formed in the suture ring seat and is locked with a screw thread head at one end of the connection hinge pin by a nut to be arranged on the suture ring seat, so that the connection hinge pin freely rotates in the through hole; the blood pump connection assembly comprises an inlet sintering pipe sleeved on an inner pipe of an inlet of a blood pump; the periphery of the inlet sintering pipe is provided with a connecting groove; and by rotating the connection hinge pin, a cylindrical surface on a circular arc tangent plane, which is arranged on the connection hinge pin, falls into the connecting groove and the suture ring seat is clamped and fixed on the inlet sintering pipe. The heart ventricle connection assembly has a simple structure, has a small axial size after connection and is beneficial for being implanted into a human body to stably play functions; and by the device designed by the invention, rapid connection of a heart ventricle auxiliary device and the heart can be implemented and not only is time of the whole operation process shortened, but also operation risk is reduced.

Owner:苏州同心医疗科技股份有限公司

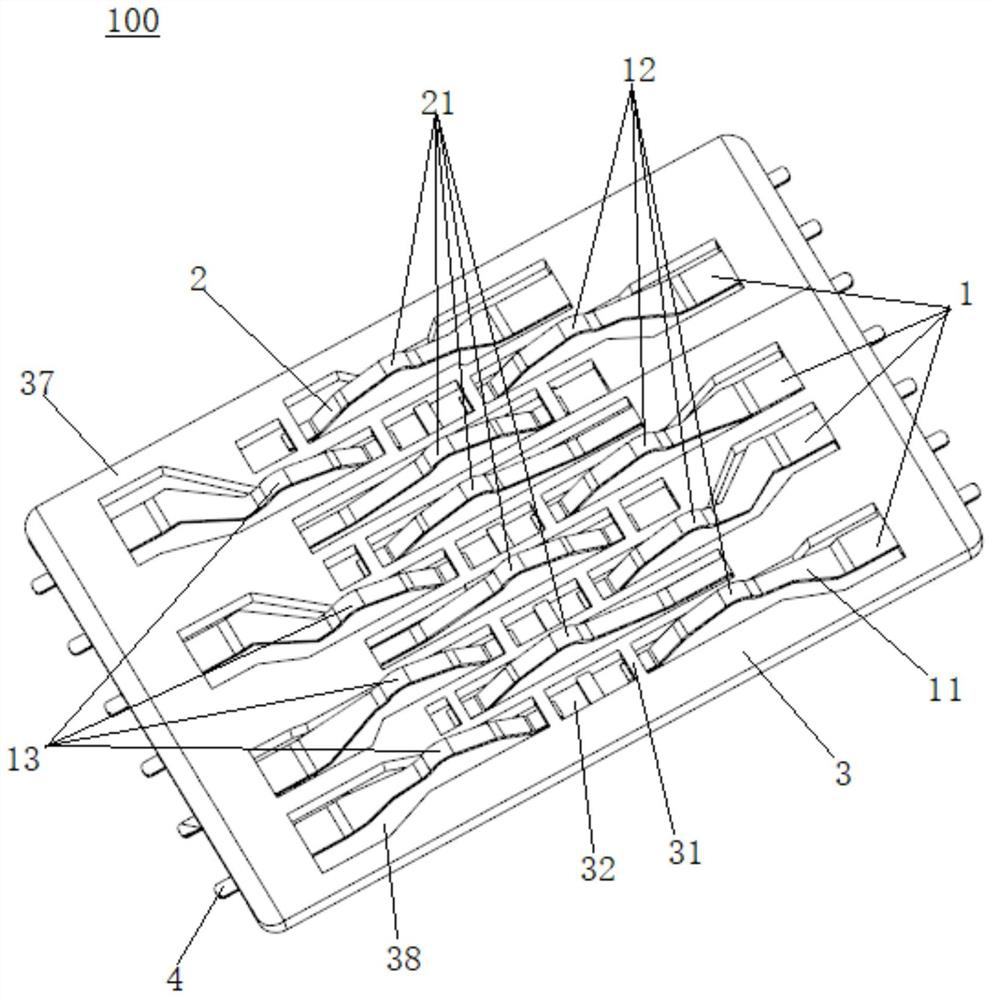

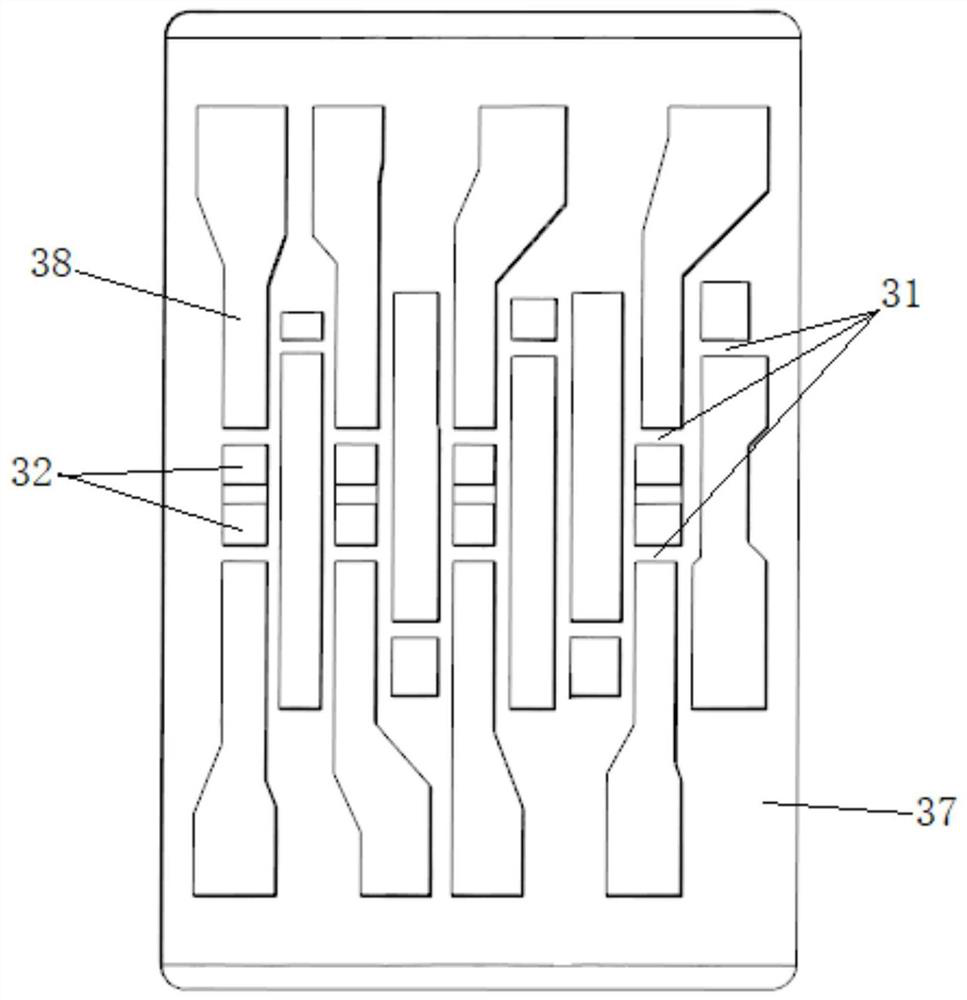

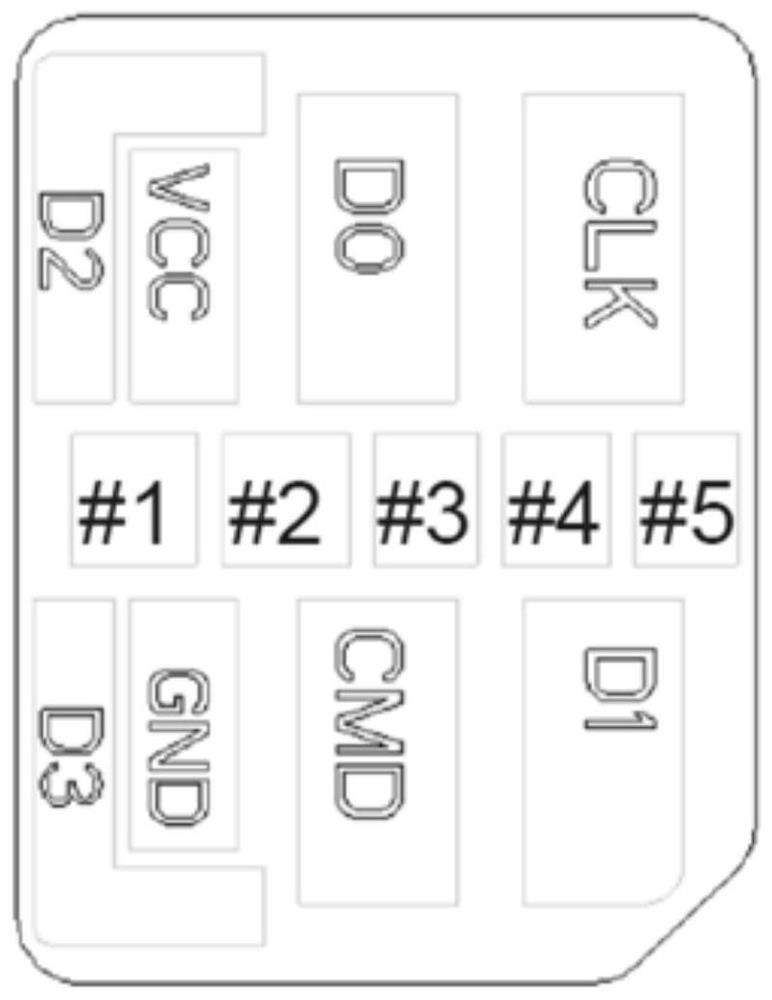

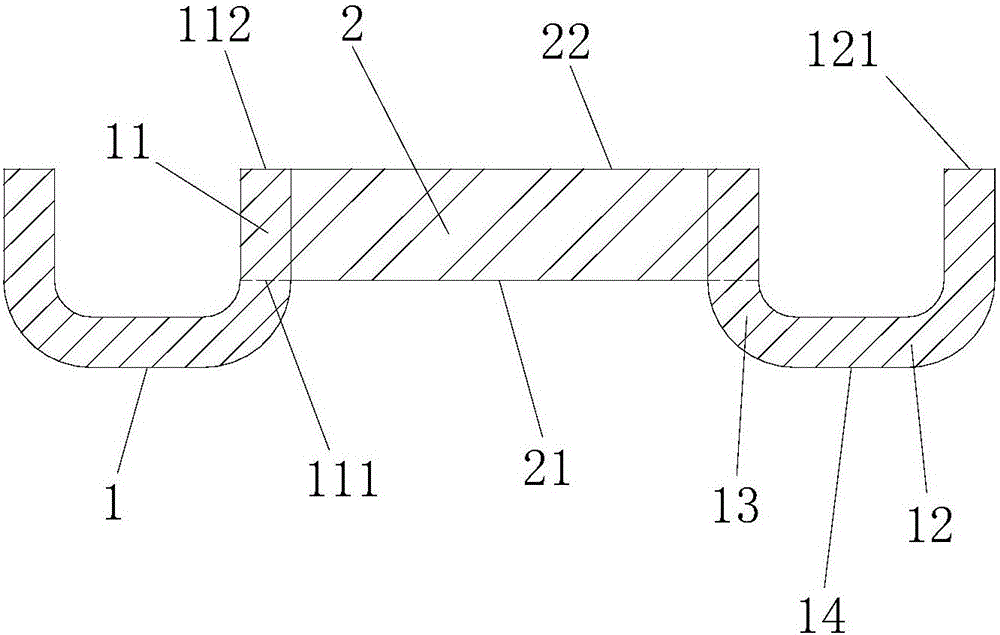

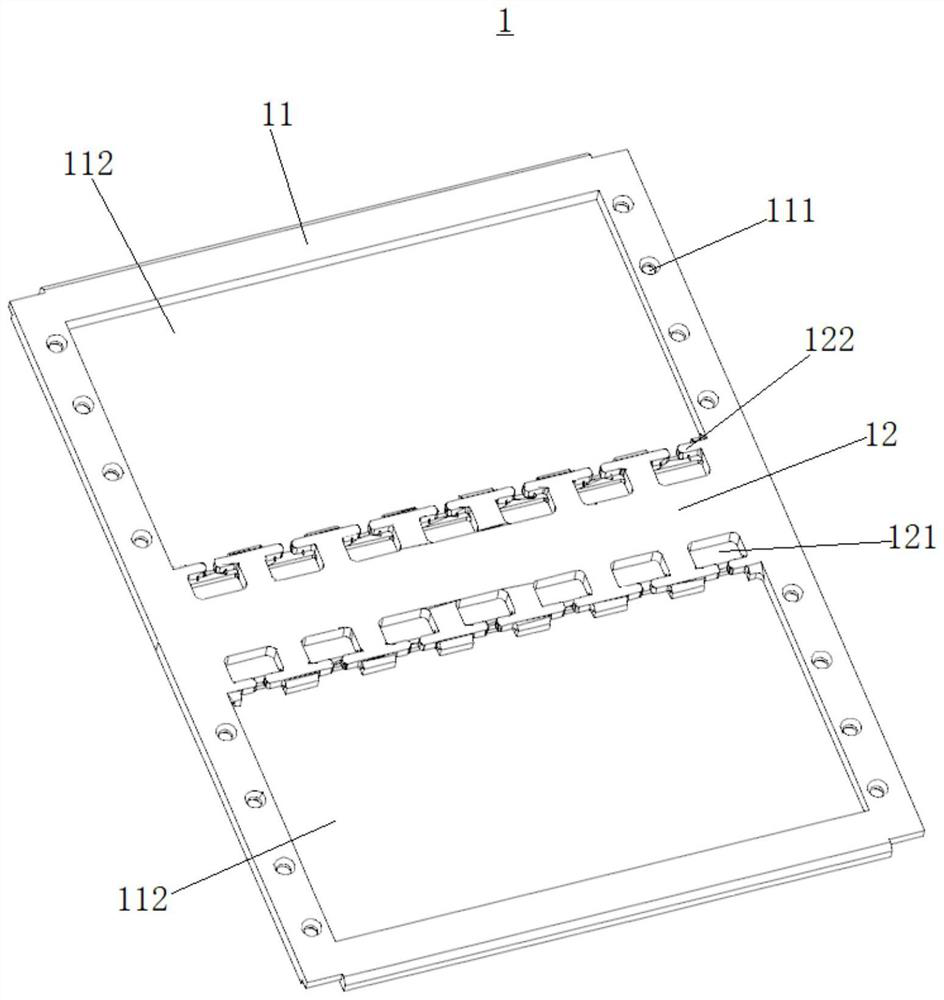

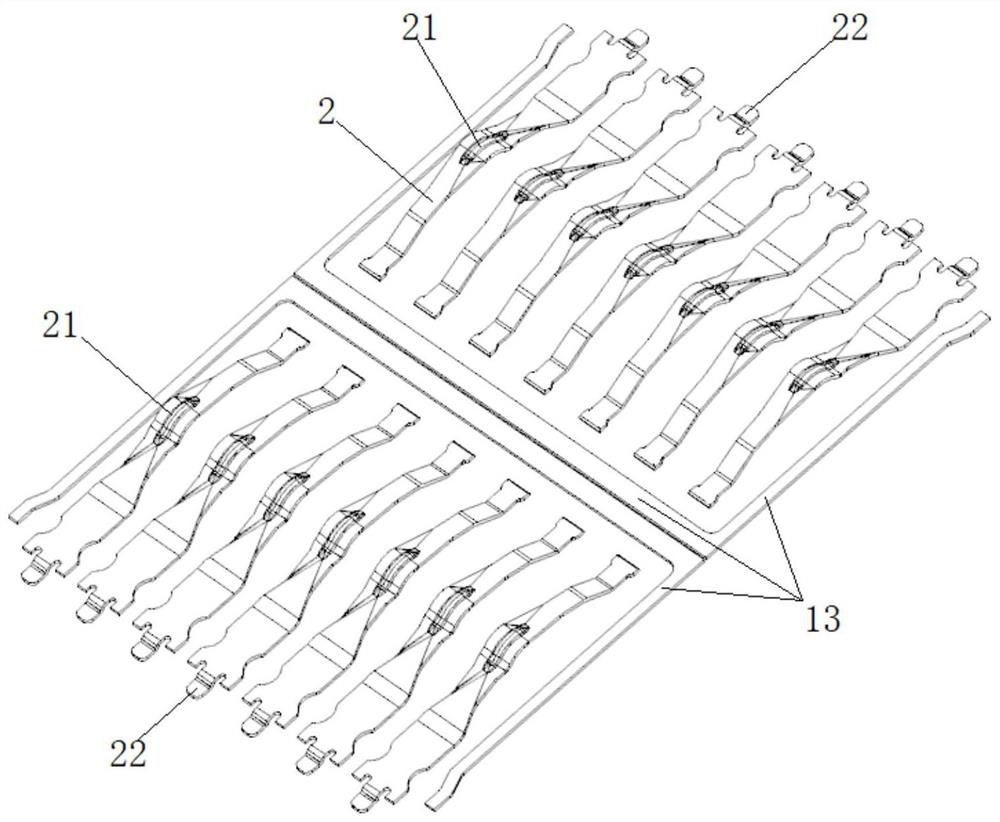

Card base connector for realizing Nano SD 2.0 high-speed transmission

PendingCN113054457ANo size increaseMeet high-speed transmission needsCoupling contact membersCard holderEmbedded system

The invention discloses a card base connector for realizing Nano SD 2.0 high-speed transmission. The card base connector comprises a holding piece and a plurality of PIN terminals embedded and formed in the holding piece, wherein the PIN terminals comprise eight first PIN terminals meeting the communication requirement of an SIM card and a Nano SD card, the eight first PIN terminals form a first group of contact points and a second group of contact points which are connected with corresponding contact points of an SIM card or a Nano SD card, the first group of contact points and the second group of contact points are oppositely distributed, the PIN terminal further comprises a high-speed PIN terminal group meeting high-speed transmission, the high-speed PIN terminal group comprises 3-8 second PIN terminals, and the high-speed PIN terminal group is provided with a third group of contact points. The card base connector can be compatible with a SIM card and a Nano SD card at the same time, high-speed transmission can be achieved, the Nano SD2.0 protocol communication requirement is met, the universality of the mobile phone card holder is greatly improved, and the market requirement is better met.

Owner:鸿日达科技股份有限公司

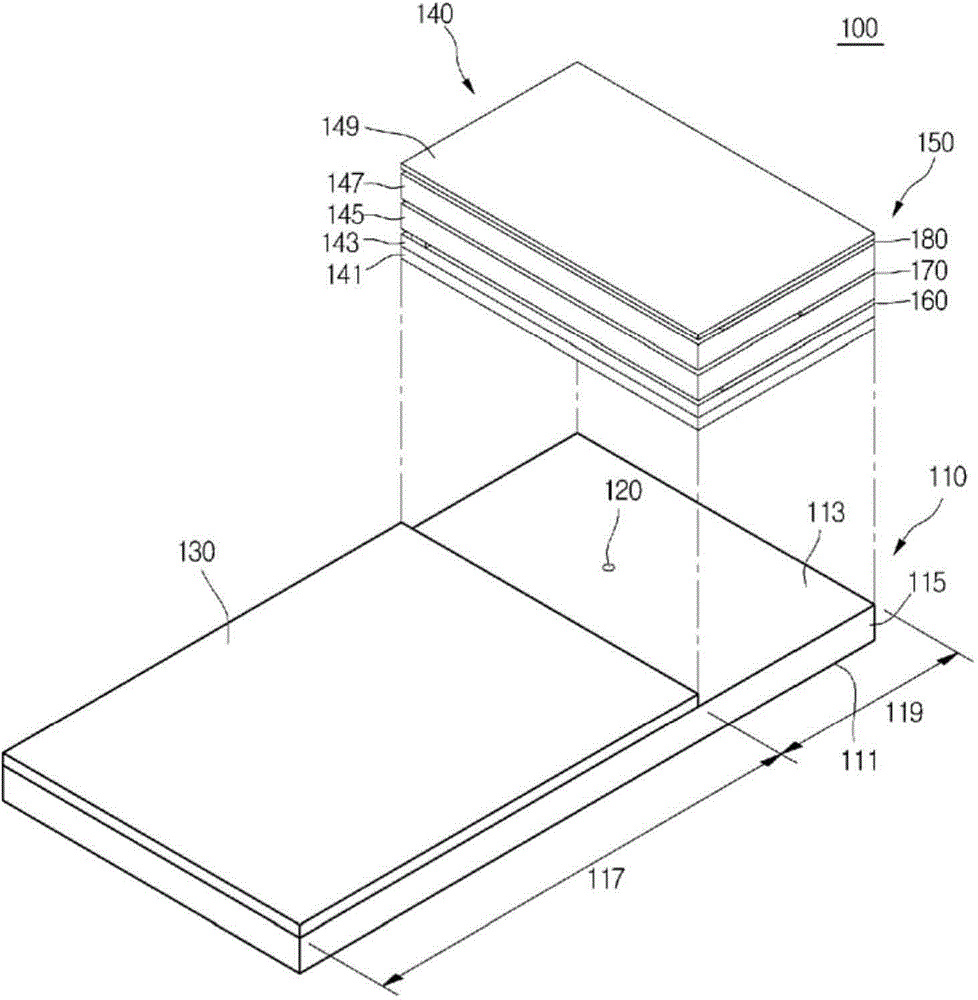

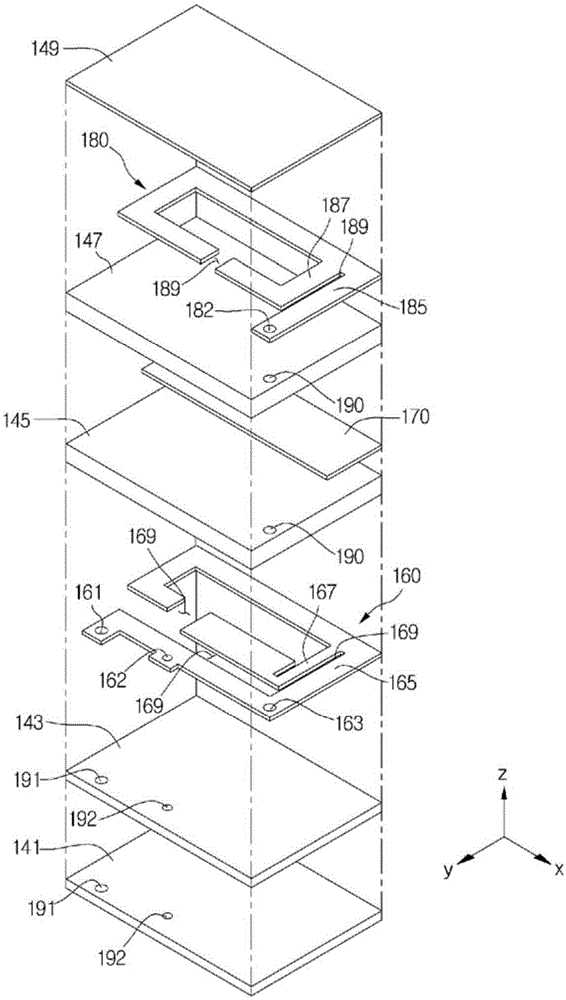

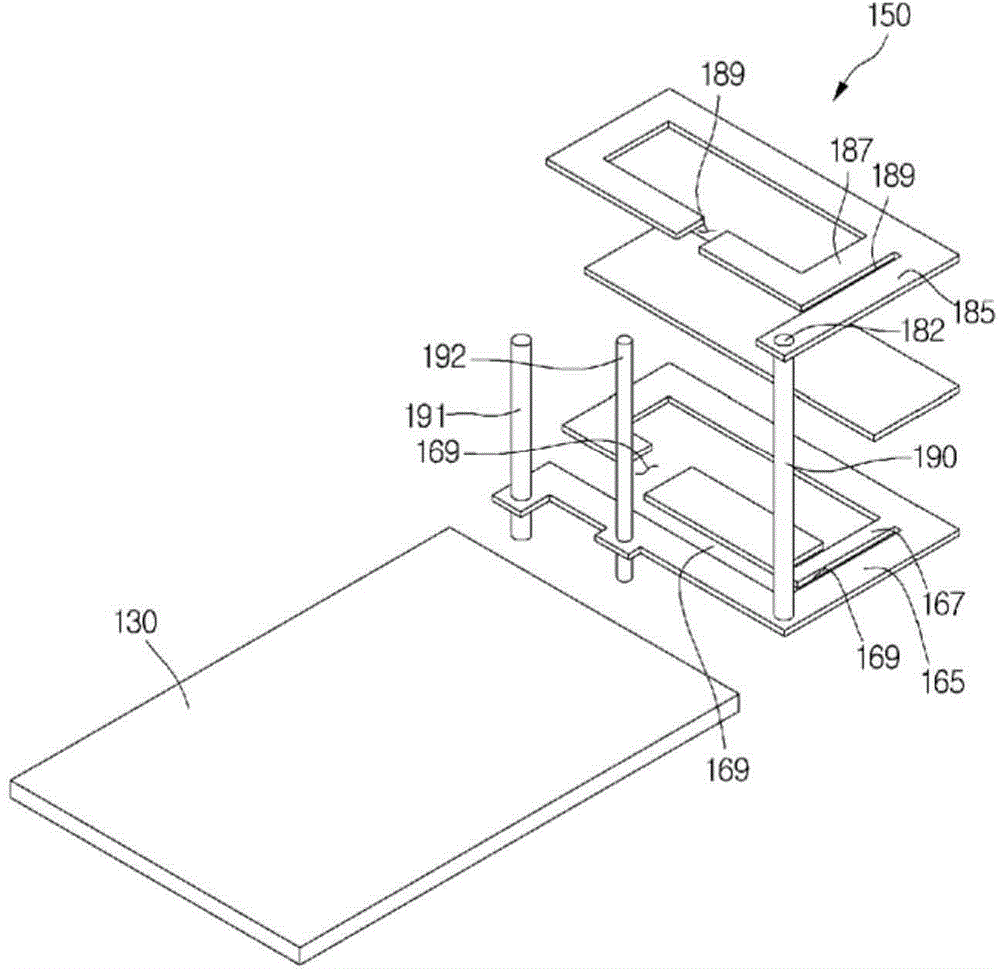

Antenna apparatus

ActiveCN104662735AExtended resonant frequency bandNo size increaseSimultaneous aerial operationsAntenna supports/mountingsResonanceAntenna element

Disclosed is an antenna apparatus. The antenna apparatus includes a lower antenna element; an upper antenna element on the lower antenna element; and an intermediate ground element interposed between the lower antenna element and the upper antenna element and overlapping with the lower antenna element and the upper antenna element. The antenna apparatus may have an expanded resonance frequency band.

Owner:LG INNOTEK CO LTD

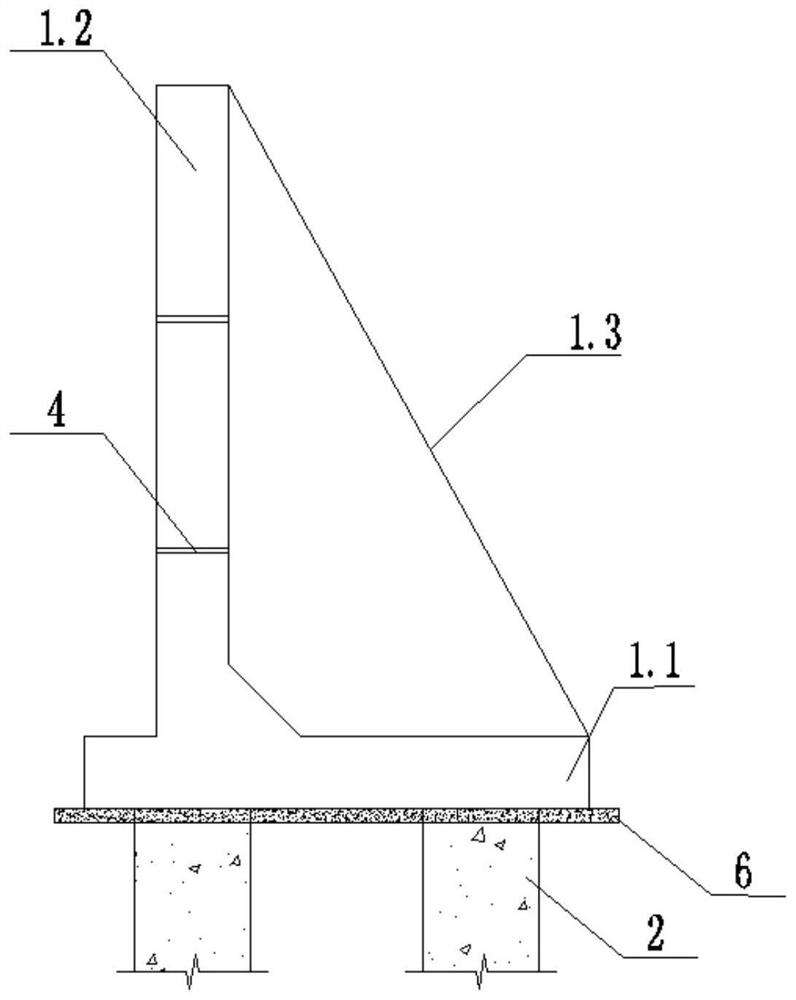

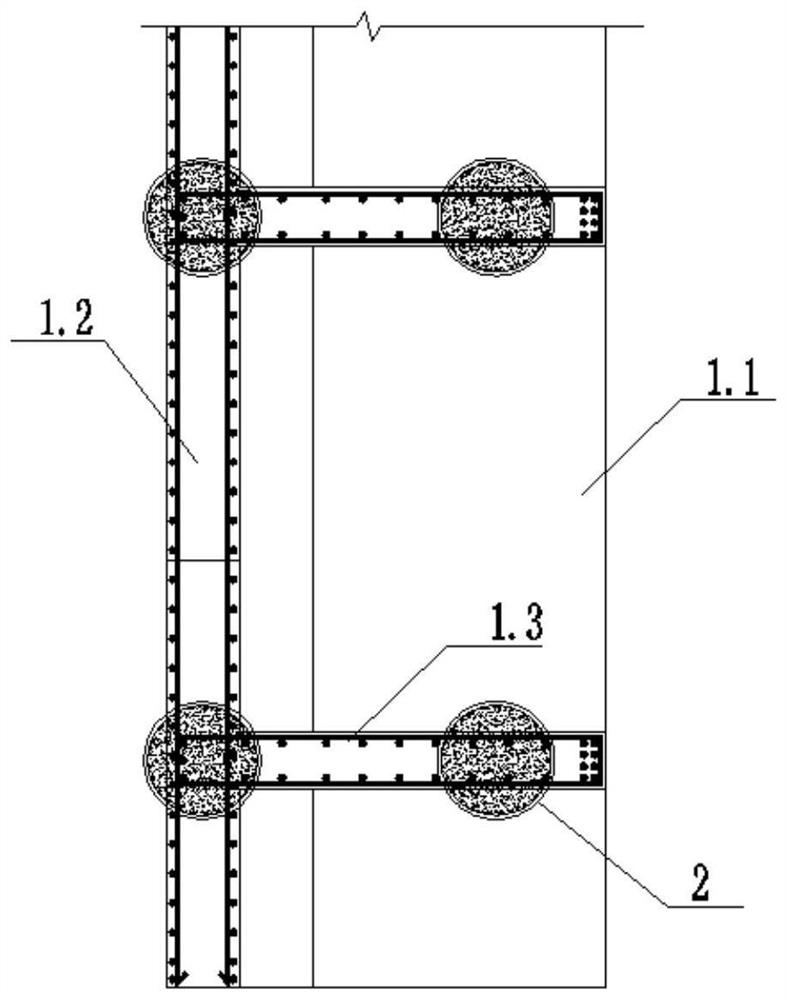

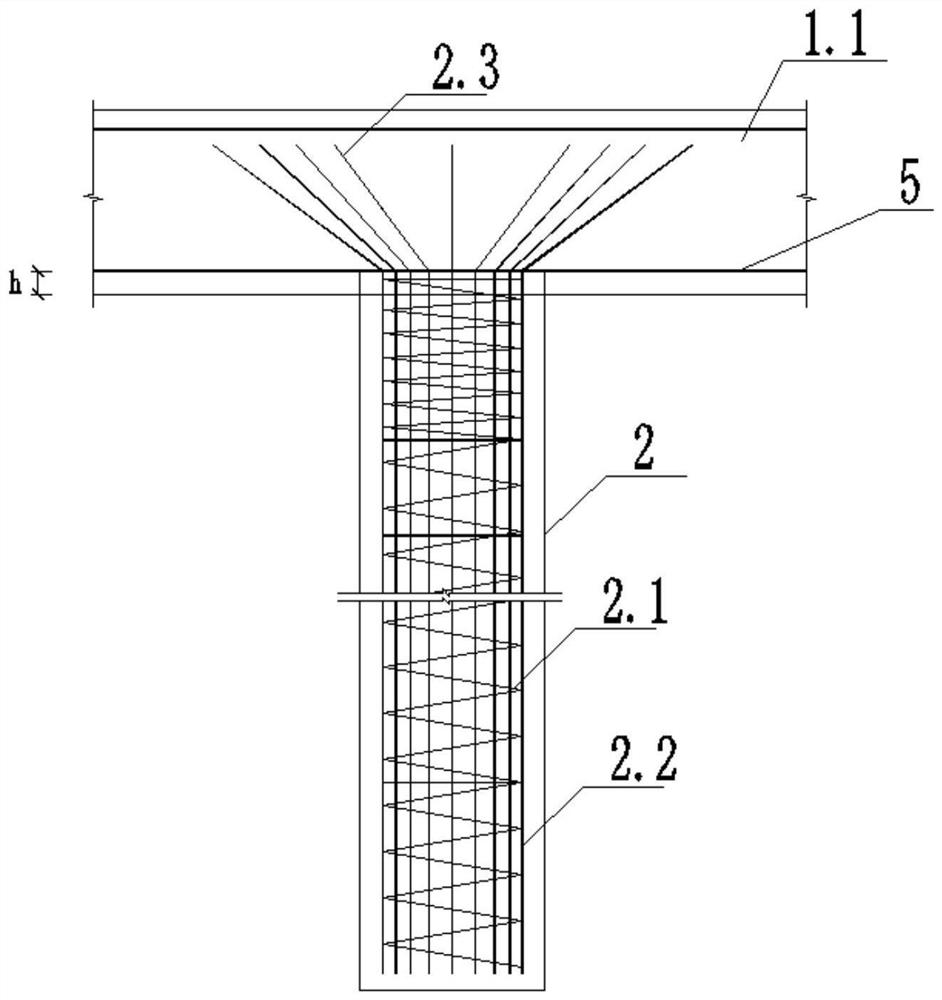

Pile-bearing supporting arm type retaining wall

PendingCN113047336ANo size increaseHigh pressure resistanceArtificial islandsUnderwater structuresRetaining wallBearing capacity

The invention discloses a pile-bearing supporting arm type retaining wall. The pile-bearing supporting arm type retaining wall comprises a bottom plate, a vertical arm fixed to the bottom plate and a rib plate used for connecting the bottom plate with the vertical arm; and a cast-in-situ bored pile is fixedly arranged at the bottom of the bottom plate, and the top of the cast-in-situ bored pile extends upwards into the bottom plate. According to the pile-bearing supporting arm type retaining wall, the cast-in-situ bored pile is only arranged below the bottom plate of the supporting arm type retaining wall, the cast-in-situ bored pile is in rigid connection with the bottom plate, the structure is simple, and the stress and force transmission ways are clear; the cast-in-situ bored pile has high pressure resistance, pulling resistance and horizontal external force bearing capacity; and the bottom plate transmits the dead weight, the upper load, the pressure borne by the vertical arm and other loads to a pile foundation, then the loads are transmitted to foundation soil through the pile foundation, and the purpose of improving the anti-overturning force, the anti-sliding force and the foundation bearing capacity on the premise that the size of the bottom plate is not increased is achieved.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

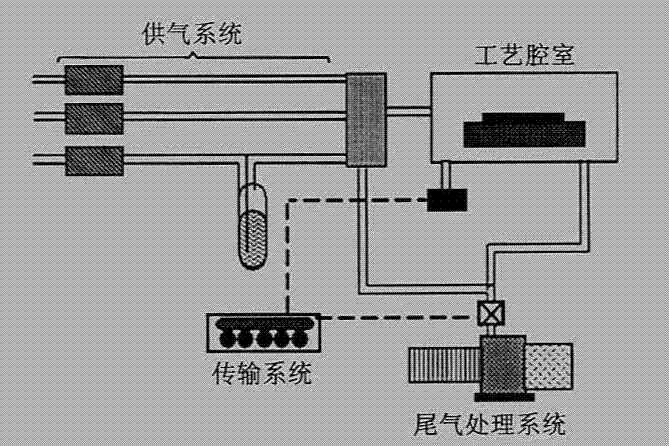

A substrate carrying device and substrate processing equipment using the device

ActiveCN102560636BIncrease production capacityIncrease profitSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringUtilization rate

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A device structure and implementation method for improving the reverse breakdown voltage of gan L-FER

ActiveCN108666360BEliminate leakage current injectionImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionLeakage (electronics)

The invention discloses a device structure for increasing the reverse breakdown voltage of GaN L-FER and a manufacturing method thereof. The structure includes a substrate, a GaN or AlN buffer layer, an intrinsic GaN channel layer, and an intrinsic AlGaN barrier layer , dielectric passivation layer, anode double Schottky contact and cathode ohmic contact. Epitaxially grow AlGaN / GaN heterojunction material on the substrate, and form ohmic contact and planar isolation on the structure, further form the anode structure of double Schottky contact, and finally deposit the passivation layer to realize the passivation of the device. The present invention utilizes the anode structure of double Schottky contacts, and the Schottky contacts have a certain shielding effect on the high voltage in the reverse breakdown process, thereby reducing the injection from the anode to the cathode through the device channel barrier layer or buffer layer. leakage current, which in turn increases the reverse breakdown voltage of the device. The implementation method of the invention is simple, and the reverse breakdown voltage of the GaN L-FER can be greatly improved so as to broaden its application in the field of power electronics.

Owner:PEKING UNIV

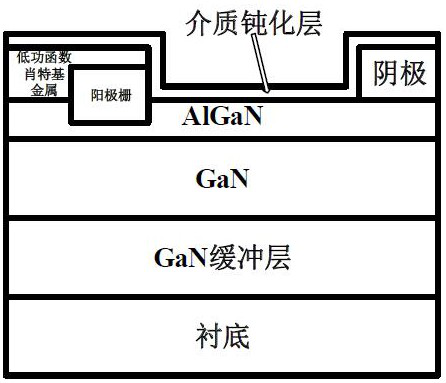

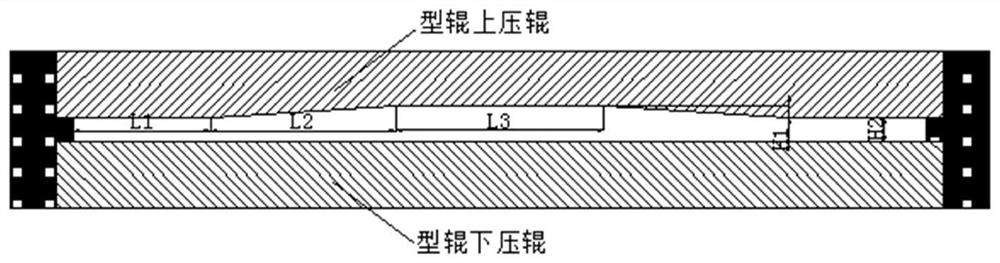

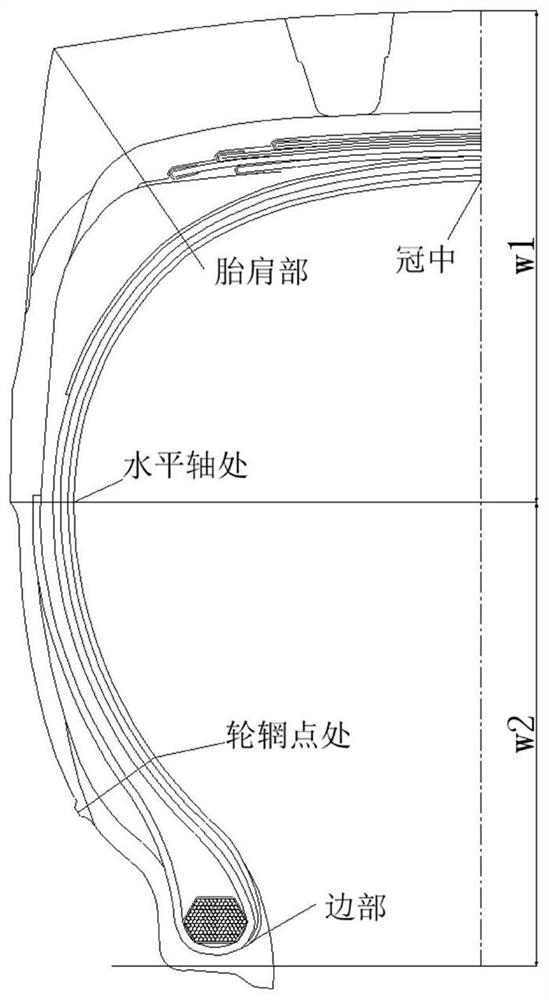

Tire lining layer manufacturing method

PendingCN114103205AImprove finished product qualityReduce calender widthTyresRubber sheetComposite material

The invention belongs to the technical field of tire manufacturing, and particularly relates to a tire lining layer manufacturing method which comprises the following two modes: mode 1, when the total width of a lining layer is smaller than 1000mm, the lining layer is directly pressed and applied together by adopting a calendaring method; in the second mode, when the total width of the lining layer is larger than or equal to 1000 mm, the lining layer is pasted with a needed rubber sheet in advance for calendaring, a forming roller calendaring rubber sheet and a flat roller calendaring rubber sheet are obtained, then at least one layer of forming roller calendaring rubber sheet and at least one layer of flat roller calendaring rubber sheet are selected according to the thickness requirement of the tire, and the lining layer is pasted into a corresponding shape; and the lining layer composite part is obtained. According to the lining layer application mode provided by the invention, the calendering sizes of the airtight layer and the transition layer can be reduced, and the production efficiency is improved; the maximum calendering width can be reduced, and the thickness of an airtight layer or a transition layer film can be controlled at the same time; and meanwhile, the maximum calendering width is reduced, so that the equipment size requirement is reduced, and the equipment cost is greatly reduced.

Owner:SAILUN GRP CO LTD

Optical transmission window for atomic clock

ActiveCN106707725AReduce the chance of damageImprove yieldApparatus using atomic clocksMountingsEngineeringAtomic clock

The invention discloses an optical transmission window for an atomic clock; the optical transmission window comprises sleeves and optical lenses arranged in the sleeves; a body wall of each sleeve comprises a vertical sidewall portion and an extension portion positioned at the bottom end of the vertical sidewall portion and peripherally extended out from the bottom end of the vertical sidewall portion; the peripheral sidewall of each optical lens is hermetically fixed to the inner wall surfaces of the vertical sidewall portions of the corresponding body walls; the bottom of each optical lens is flush with the bottom edges of the vertical sidewall portions of the body walls. By modifying the structure of the optical transmission window, the need for batch coating of optical transmission windows is met, and the problem is solved that optical lenses in the multiple traditional optical transmission windows cannot be coated in batch at a time through an existing coating machine due to their structure limits.

Owner:NO 12 RES INST OF CETC

Multi-polarization microstrip patch antenna loading zero-order resonator

ActiveCN102570043BNo size increaseAvoid defectsRadiating elements structural formsMicrostrip patch antennaResonance

The invention provides a multi-polarization microstrip patch antenna loading a zero-order resonator. The antenna comprises an upper-layer microstrip structure, a middle medium base plate and a bottom-layer metal floor, wherein the upper-layer microstrip structure is arranged on one surface of the middle medium base plate and comprises a microstrip transmission line, a coupling feed part and an antenna main body; the microstrip transmission line is vertically connected with the coupling feed part; the antenna main body and the microstrip transmission line are arranged at the two sides of the coupling feed part respectively; a gap is reserved between the antenna main body and the coupling feed part; the antenna main body consists of two microstrip patch parts and a zero-order resonance part; and the zero-order resonance part is arranged between the two microstrip patch parts and consists of an upper-layer microstrip patch and a grounding metal column vertically arranged between the upper-layer microstrip patch and the middle medium base plate. In the antenna provided by the invention, by combining the traditional microstrip patch antenna with a second-order mushroom type zero-order resonator, the shortcomings of respective polarization direction and radiation patterns of the traditional microstrip patch antenna and the second-order mushroom type zero-order resonator are overcome, so that good radiation characteristic is realized.

Owner:广州桑瑞科技有限公司

A passive high-temperature pressure sensor based on the principle of microwave scattering and its preparation method

ActiveCN105004469BReduce lossIncrease distanceFluid pressure measurement by electric/magnetic elementsEngineeringHigh pressure

The invention relates to the technical field of pressure sensors, specifically a passive high-temperature pressure sensor based on the principle of microwave scattering measurement and its preparation method, which solves the problems of many defects in existing pressure measurement methods in harsh environments such as high temperatures, including cylindrical bases and The sealing diaphragm is provided with a concave cylindrical cavity in the base, and four symmetrically distributed inner cylinders are arranged in the center of the concave cylindrical cavity. The height of the inner cylinders is lower than the upper end surface of the concave cylindrical cavity. The upper surface of the inner cylinder is sputtered with a metal layer; the upper surface of the sealing diaphragm is sputtered with a microstrip antenna, the lower surface is sputtered with a ground plane, and a rectangular coupling gap is opened on the lower surface; the base and the sealing diaphragm are bonded to form a microwave resonant cavity. The design is reasonable, the sensitivity is high, the stability is good, and it can work for a long time in harsh environments such as high temperature and high pressure, and realizes a passive high-temperature ceramic pressure sensor based on wireless measurement of microwave scattering.

Owner:ZHONGBEI UNIV

A Broadband Dual-Polarized Microstrip Antenna Subarray with Filtering and Scaling Functions

ActiveCN110797649BNo size increaseSuppression of interfering signalsAntenna adaptation in movable bodiesRadiating elements structural formsMicrostrip antenna arrayBroadband microstrip antenna

The application discloses a broadband dual-polarized microstrip antenna sub-array with filtering and calibration functions, including a radiation layer, a paper honeycomb support layer and a functional layer, the functional layer includes: the upper surface of the upper printed board is provided with an upper metal surface , etched with "H"-shaped slits, the first "H"-shaped slits are arranged along the vertical direction of the upper metal surface, and the second "H"-shaped slits are arranged along the horizontal direction; the lower printed board is provided with polarization feed Network, including "T" stripline and characteristic stripline, "T" stripline and the first "H" shaped slot perpendicular to the polarization feed network, denoted as horizontal polarization feed network, and the second "H" If the "shaped gap is vertical, it is recorded as a vertical polarization feed network; metallized via holes are provided on the metal surface of the lower layer, and the metallized via holes pass through the lower layer printed board and are symmetrically distributed on both sides of the polarized feed network. Through the technical solution in this application, a dual-polarized broadband microstrip antenna sub-array with power distribution, filtering and calibration functions is realized.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

14-pin Nano SD high-speed transmission card seat connector

PendingCN113394583AReduce weightImprove versatilitySecuring/insulating coupling contact membersCoupling contact membersEmbedded systemMechanical engineering

The invention discloses a 14-pin Nano SD high-speed transmission card holder connector, which comprises a holding piece and two rows of pin terminals embedded and formed in the holding piece, the two rows of pin terminals are symmetrically distributed and respectively positioned in the upper half region and the lower half region of the holding piece, and each row of pin terminals comprises seven pins arranged at intervals; and the middle part of each pin protrudes upwards to form a contact point in contact with the communication card. The SIM card and the Nano SD card can be compatible at the same time, high-speed transmission can be achieved, the Nano SD 2.0 protocol communication requirement is met, the universality of the mobile phone card holder is greatly improved, the market requirement is better met, the size is small, the thickness is small, and the ultrathin and miniaturized design requirement is met.

Owner:鸿日达科技股份有限公司

Semiconductor device

InactiveCN100390969CReduce inductanceSmall sizeCross-talk/noise/interference reductionSemiconductor/solid-state device detailsSemiconductor deviceSemiconductor components

The suppression of the scaling up of a semiconductor device and the reduction of noises. A semiconductor device comprises a base (5) provided with skin layers (9, 11) on both faces of a core layer (7) formed of a printed wiring board and a semiconductor element (1) mounted on the base (5). The semiconductor element (1) is bonded to one skin layer (9) with a bonding member (3), and external terminals (55) are arranged on the other skin layer (11). The core layer (7) has through holes (41, 43, 45, 75, 77) which electrically connect the semiconductor element (1) and the external terminals (55). The through holes (41, 43,45, 75, 77) consist of array through holes (41, 43, 45) disposed in accordance with the array of the external through holes (55) and one or more additional through holes (75, 77) provided between the array through holes (41, 43, 45).

Owner:HITACHI LTD

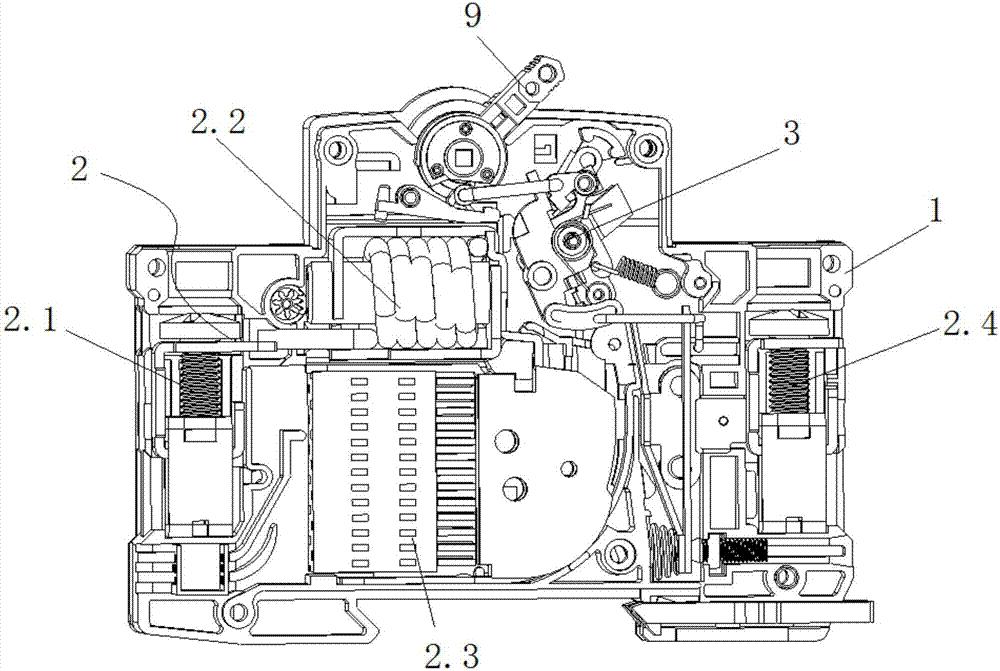

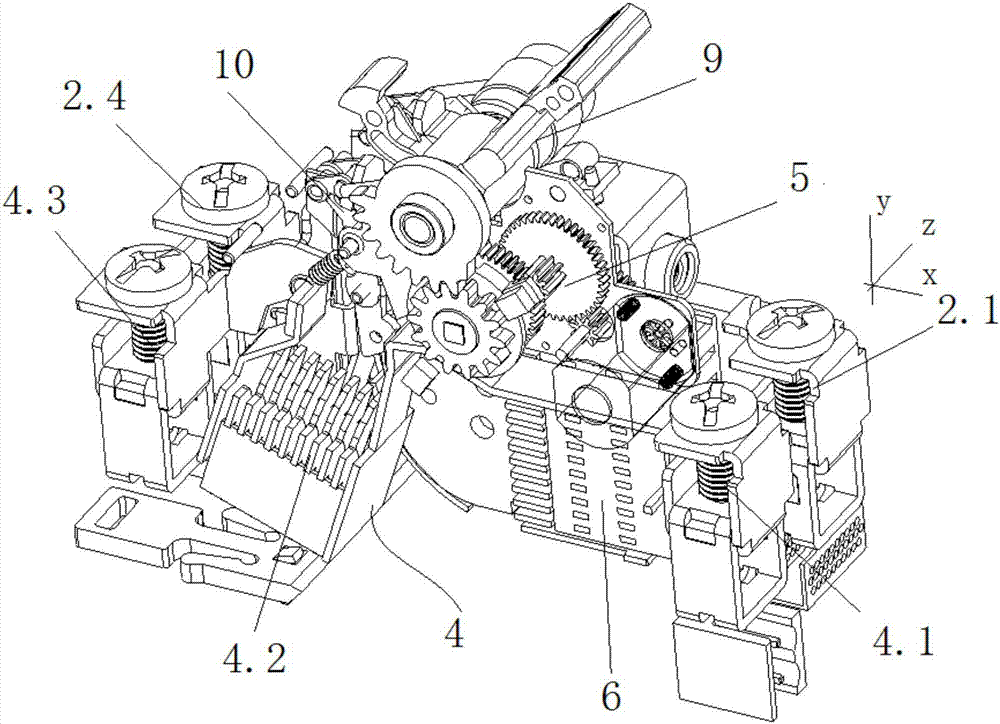

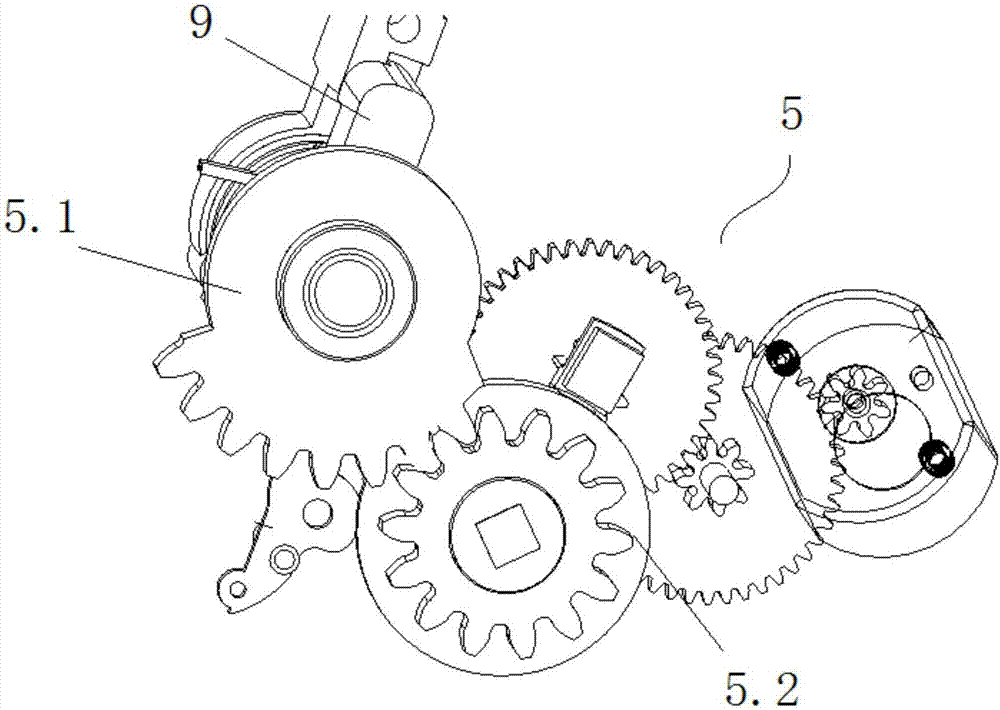

Circuit breaker with automatic control function

InactiveCN106992104ANo size increaseNo delete functionProtective switch terminals/connectionsProtective switch operating/release mechanismsMotor driveAutomatic control

The invention discloses a circuit breaker with an automatic control function. The circuit breaker comprises a housing body. A live line mechanism and a null line mechanism are oppositely arranged in the housing body in the first direction. The live line mechanism comprises a live line conduction mechanism and a live line driving assembly. The null line mechanism comprises a null line conduction mechanism and a null line driving assembly. A motor driving assembly is used for driving the live line driving assembly and the null line driving assembly. The live line conduction mechanism and the null line conduction mechanism are arranged in the first direction in the housing body. The motor driving assembly and the null line driving assembly are oppositely arranged in the second direction and are arranged opposite to the null line conduction mechanism in the third direction. The live line driving assembly and the null line driving assembly are oppositely arranged in the first direction. According to the invention, proper layout of each assembly is finished on the premise that one set of mechanisms are omitted in parts of the mechanisms, so the whole size is not increased without deletion, and overall proper arrangement is finished.

Owner:JAECELE ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com