Device structure and implementation method for improving GaN L-FER reverse breakdown voltage

A technology of reverse breakdown voltage and device structure, which is applied in the field of microelectronics, can solve the problems of diode on-resistance affecting forward current characteristics, increasing the size of rectifier tubes, and decreasing response speed, so that the forward characteristics will not deteriorate, Improve the reverse breakdown voltage, easy to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be described more fully with reference to the accompanying drawings, in which embodiments and their realization are shown, the described embodiment is only one form of realization in the present invention, that is, the present invention should not be interpreted are limited to the examples set forth herein. Based on the embodiment, the scope of the present invention is fully conveyed to those skilled in the art.

[0033] Hereinafter, exemplary embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

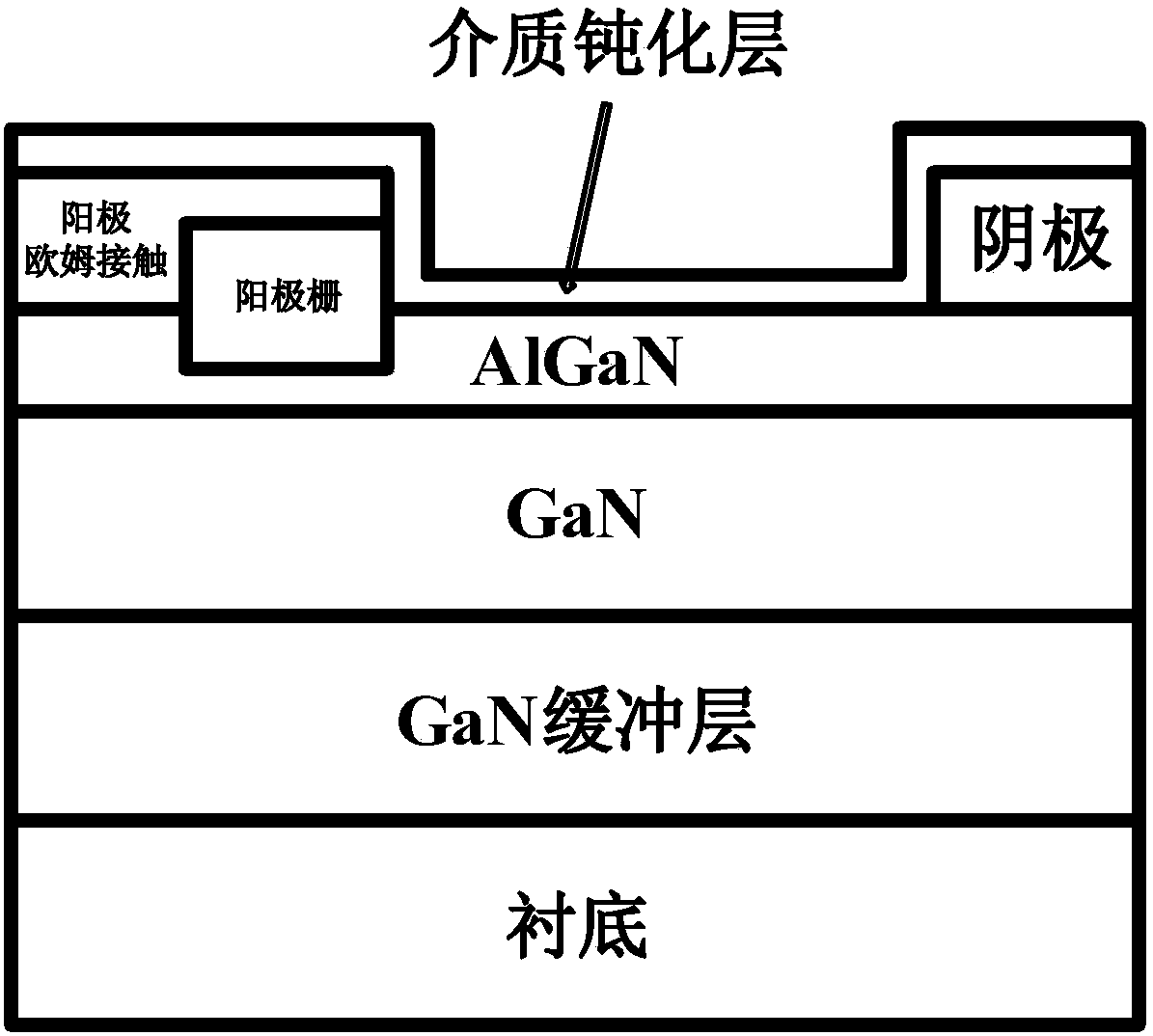

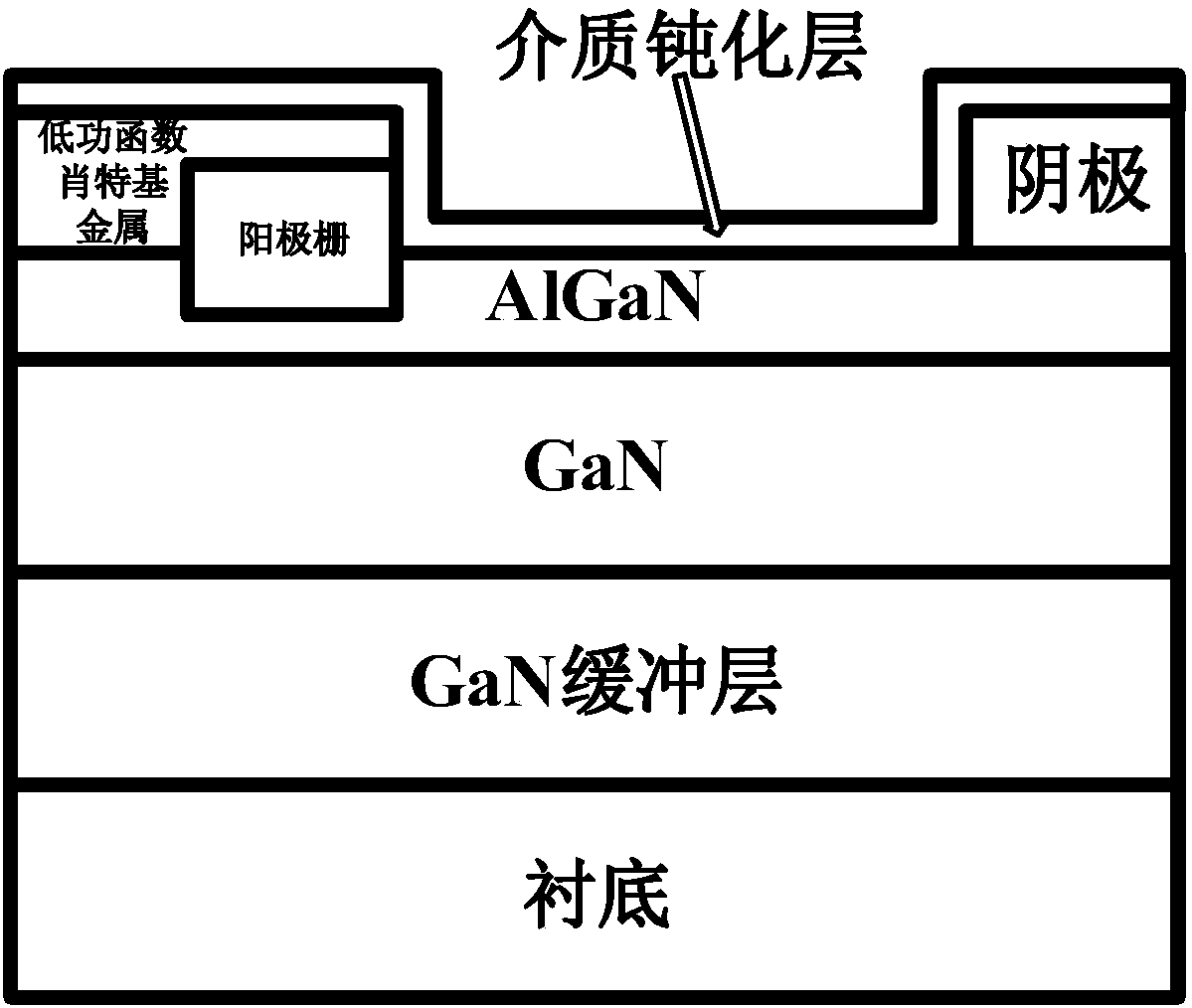

[0034] refer to figure 2 , the device structure includes a substrate, a GaN or AlN buffer layer, an intrinsic GaN channel layer, an intrinsic AlGaN barrier layer, an anode double Schottky layer, and a dielectric passivation layer in sequence from bottom to top. Its preparation method comprises the following specific steps:

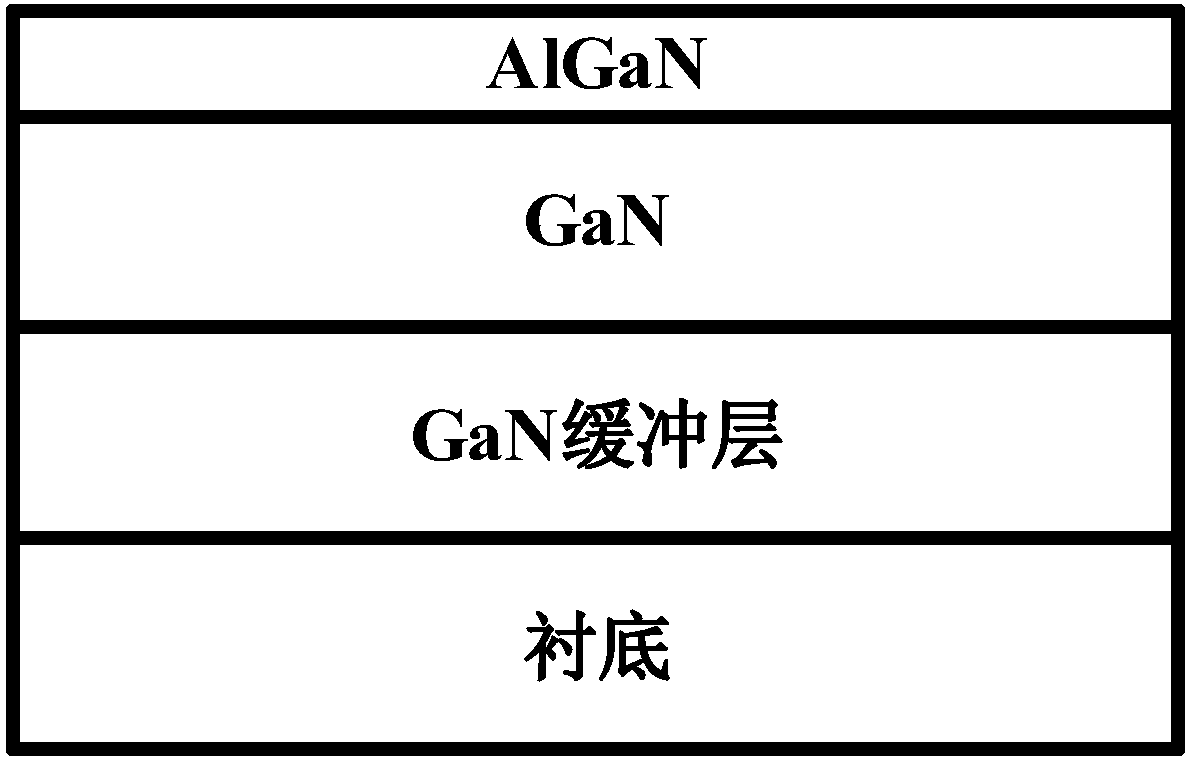

[0035] (1) if image 3 As shown, firstly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com