Tire lining layer manufacturing method

A manufacturing method and a technology for an inner liner, which are applied in the field of tire manufacturing, can solve the problems of unstable processing dimensions, frequent replacement of tooling, difficult production processes, etc., so as to improve the calendering production accuracy, reduce the maximum calendering width, and improve the quality of tire finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

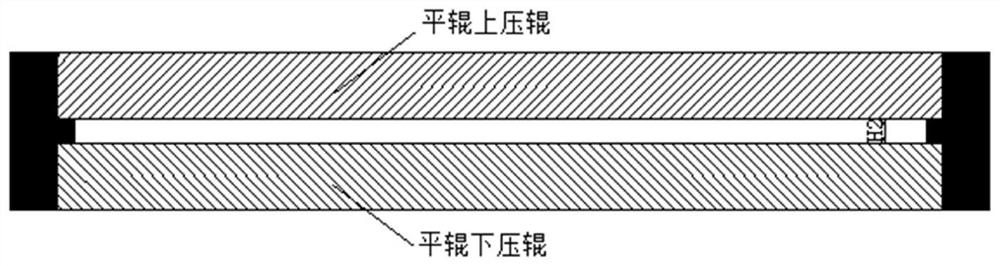

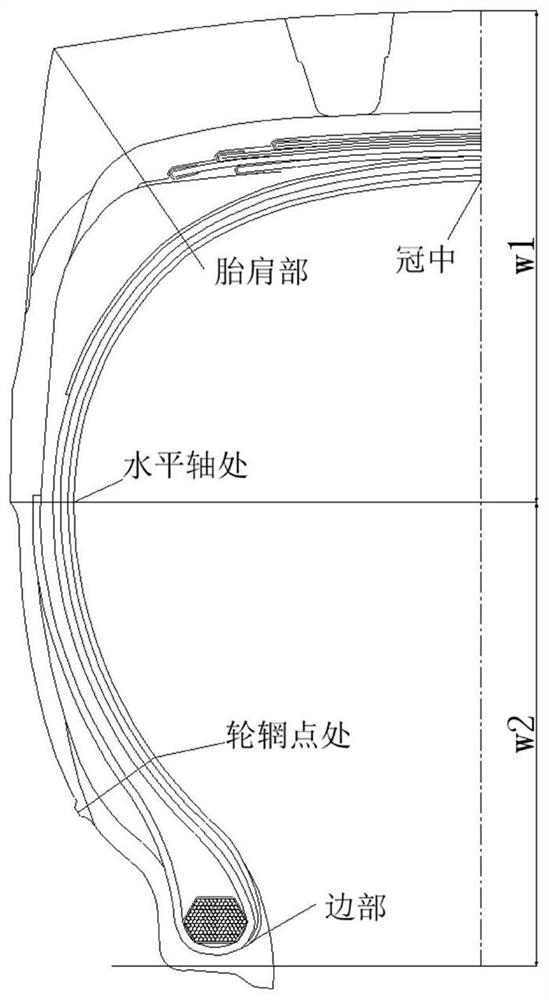

[0039] like Figure 5 As shown, for products whose total width of the inner liner is less than 1000mm, the airtight layer and the transition layer are calendered with rolls, directly calendered and extruded, and then applied together.

Embodiment 2

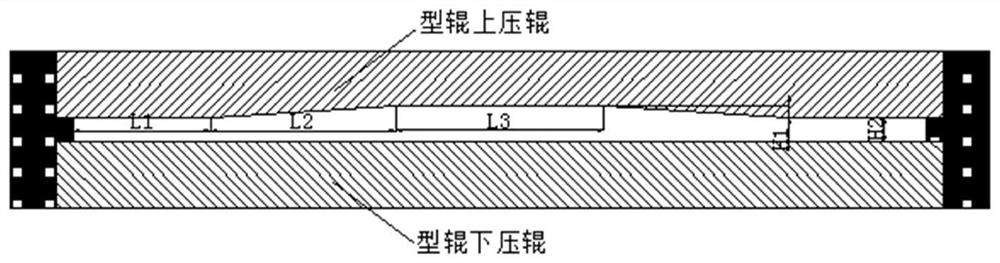

[0041] like Figure 6 As shown, for products with a total width of the inner lining layer of more than 1000mm, the product size is less than 23.5R25, and the calender cannot calender the inner liner and transition layer at one time, the following operations should be performed:

[0042] 1) Roll out inner liner 1, transition layer 1, inner liner 2, and transition layer 2 with flat rollers respectively (the width of inner liner 1 is smaller than that of inner liner 2, and the width of transition layer 1 is greater than transition layer 2), and calendered with molded rolls Exit airtight layer 3, transition layer 3;

[0043] 2) The first layer is formed by splicing airtight layers 1 and 2, and the overlapping width in the middle is 10-20mm;

[0044] 3) Arrange in the second layer with airtight layer 3;

[0045] 4) Row the third layer with transition layer 3;

[0046] 5) The transition layer 1 and 2 are spliced to form the fourth layer, and the width of the middle lap is 10-20mm...

Embodiment 3

[0049] like Figure 7 As shown, for products with a total inner liner width of more than 1000mm, the size of the product is between 23.5R25 and 29.5R25, the calender cannot roll out the inner liner and transition layer at one time, and only two layers of the inner liner cannot meet its thickness. (When the edge thickness of the airtight layer is greater than 4.0mm, it will cause edge delamination), you need to add a layer of airtight layer, as follows:

[0050] 1) Roll out the inner liner 1, the transition layer 1, the inner liner 2, and the transition layer 2 with flat rollers respectively (the width of the inner liner 1 is greater than that of the inner liner 2, and the width of the transition layer 1 is greater than that of the transition layer 2). Roll out inner liner 4, inner liner 5 (the width of inner liner 4 is less than inner liner 5), roll out inner liner 3, transition layer 3 with molded roller calendering;

[0051] 2) Use airtight layers 1 and 2 to form the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com