Manufacturing method of large-size optical fiber preform

A technology of optical fiber preform and manufacturing method, which is applied in the direction of manufacturing tools and glass manufacturing equipment, etc., which can solve the problems of large equipment load and increase of sintering furnace, and achieve the effects of small equipment load, low manufacturing cost, saving production capacity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

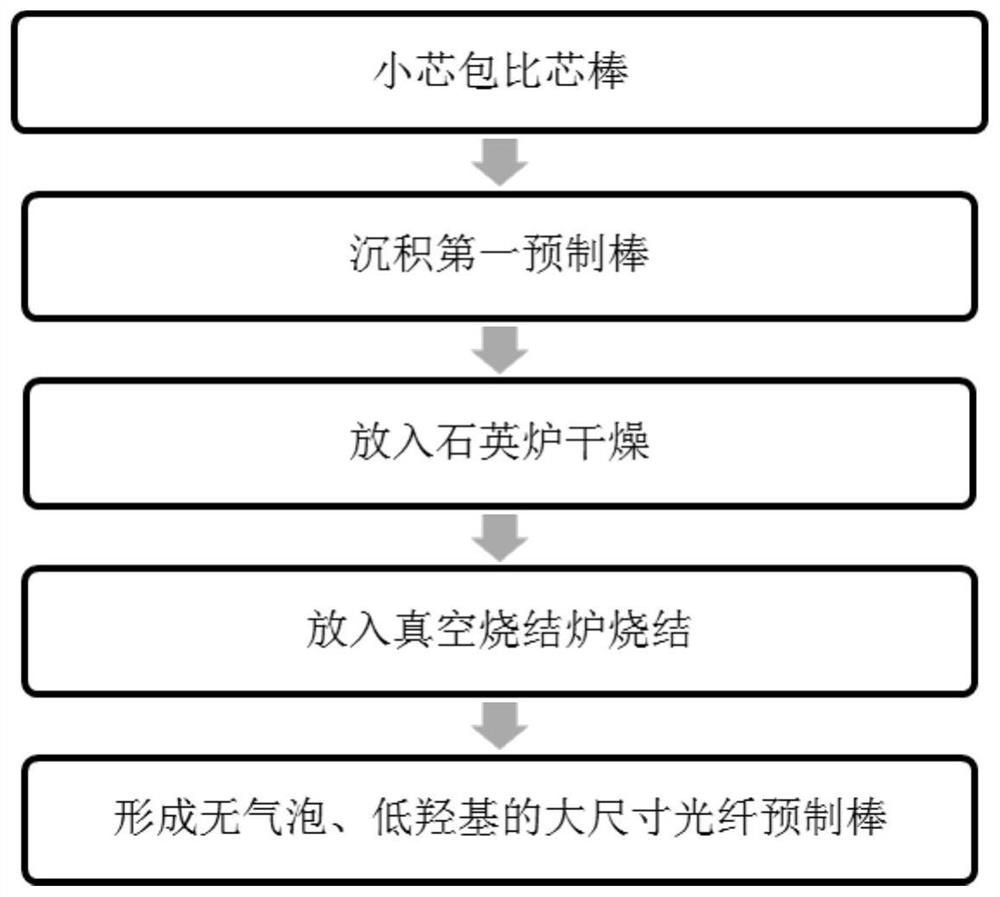

Method used

Image

Examples

Embodiment 1

[0024] Using a core rod with a core-to-package ratio of 3.6 as the target rod, deposit a porous optical fiber preform with a density of 0.42g / cm 3 , The average outer diameter is 345mm.

[0025] Put it into a quartz furnace, feed 0.7L / min of chlorine gas and 10L / min of helium gas, set the furnace temperature at 1250°C, and dry for 3 hours. After the end, the average outer diameter of the porous optical fiber preform is 246.9mm, and the density is 0.82g / cm 3 .

[0026] Finally, put it into a vacuum sintering furnace for sintering to form a transparent and bubble-free optical fiber preform with an average outer diameter of 172.6mm.

[0027] After being drawn into an optical fiber, no gas lines were found in the bare optical fiber, and the average 1383 attenuation of the optical fiber was 0.283dB / km.

Embodiment 2

[0029] Using a core rod with a core-to-cover ratio of 4.2 as the target rod, deposit a porous optical fiber preform with a density of 0.39g / cm 3 , The average outer diameter is 356mm.

[0030] Put it into a quartz furnace, feed 0.8L / min of chlorine gas and 10L / min of nitrogen gas, set the furnace temperature at 1230°C, and dry for 3 hours. After the end, the average outer diameter of the porous optical fiber preform is 255.3mm, and the density is 0.76g / cm 3 .

[0031] Finally, put it into a vacuum sintering furnace for sintering to form a transparent and bubble-free optical fiber preform with an average outer diameter of 175.4mm.

[0032] After being drawn into an optical fiber, the length of the gas-containing line of the bare optical fiber is 5km, and the average 1383 attenuation of the optical fiber is 0.271dB / km.

Embodiment 3

[0034] Using a core rod with a core-to-cover ratio of 3.8 as the target rod, deposit a porous optical fiber preform with a density of 0.45g / cm 3 , The average outer diameter is 351mm.

[0035] Put it into a quartz furnace, feed 0.6L / min of chlorine gas and 8L / min of helium gas, set the furnace temperature at 1270°C, and dry for 3 hours. After the end, the average outer diameter of the porous optical fiber preform is 255.6mm, and the density is 0.85g / cm 3 .

[0036] Finally, put it into a vacuum sintering furnace for sintering to form a transparent and bubble-free optical fiber preform with an average outer diameter of 182.1mm.

[0037] After being drawn into an optical fiber, no gas lines were found in the bare optical fiber, and the average 1383 attenuation of the optical fiber was 0.276dB / km.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com