Contact window structure, metal plug and forming method thereof, and semiconductor structure

A technology of metal plugs and contact windows, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of reduced circuit performance requirements, reduced contact area of metal layers, etc., and achieves increased contact area. The effect of increasing and reducing the contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

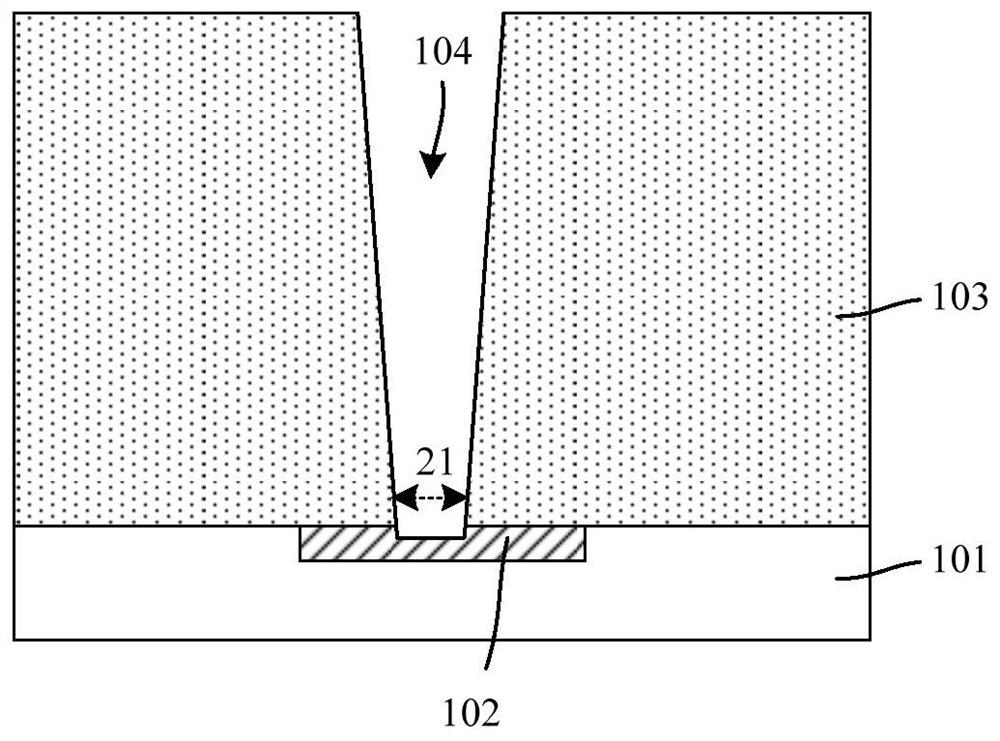

[0052] As mentioned in the background art, the shrinkage phenomenon occurs in the process of forming through holes, especially through holes with high aspect ratio. This phenomenon causes the size of the bottom of the through hole to be smaller than that of the top, and increases the contact resistance.

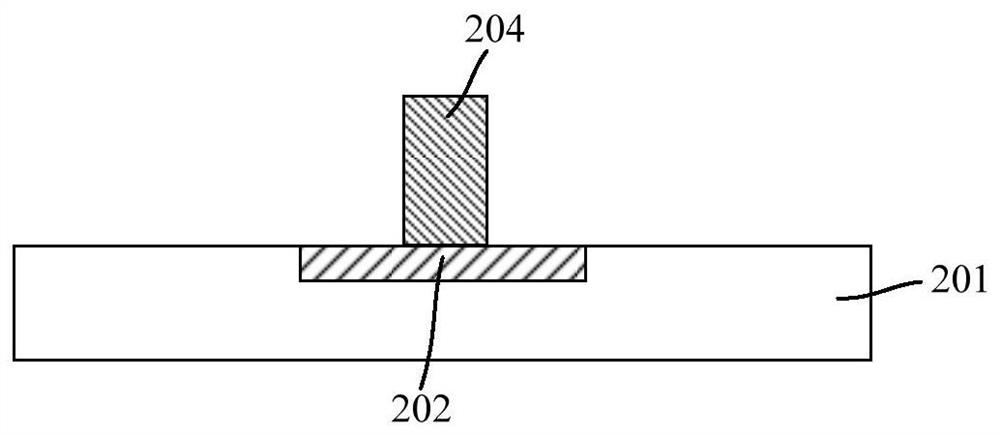

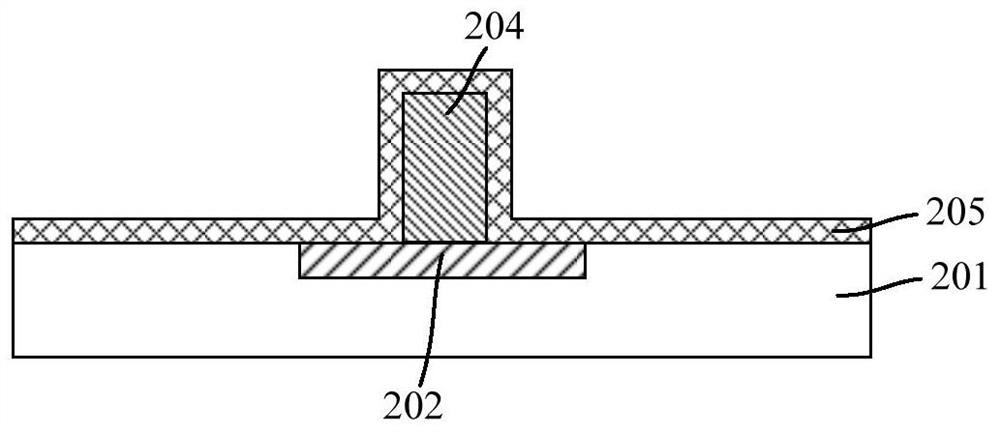

[0053]To this end, the present invention provides a contact window structure, a metal plug and a method for forming the same, and a semiconductor structure. The method for forming the contact window structure provides a target layer; an annular gasket is formed on the surface of the target layer, and the A central through hole that exposes part of the surface of the target layer is provided in the middle of the annular spacer; a dielectric layer covering the target layer and the annular spacer is formed; the dielectric layer is etched, and an etched hole communicating with the central through hole is formed in the dielectric layer. Etching holes; removing the annular spacer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com