Pile-bearing supporting arm type retaining wall

A retaining wall and arm type technology, which is applied in sheet pile walls, soil protection, water conservancy projects, etc., can solve the problem that the bearing capacity of the foundation does not meet the base stress. The problems such as limited force and anti-slip force, the bearing capacity of the foundation does not meet the base stress, etc., can achieve the effect of clear force and force transmission path, high compressive and uplift resistance and horizontal external force bearing capacity, and improve the anti-overturning force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

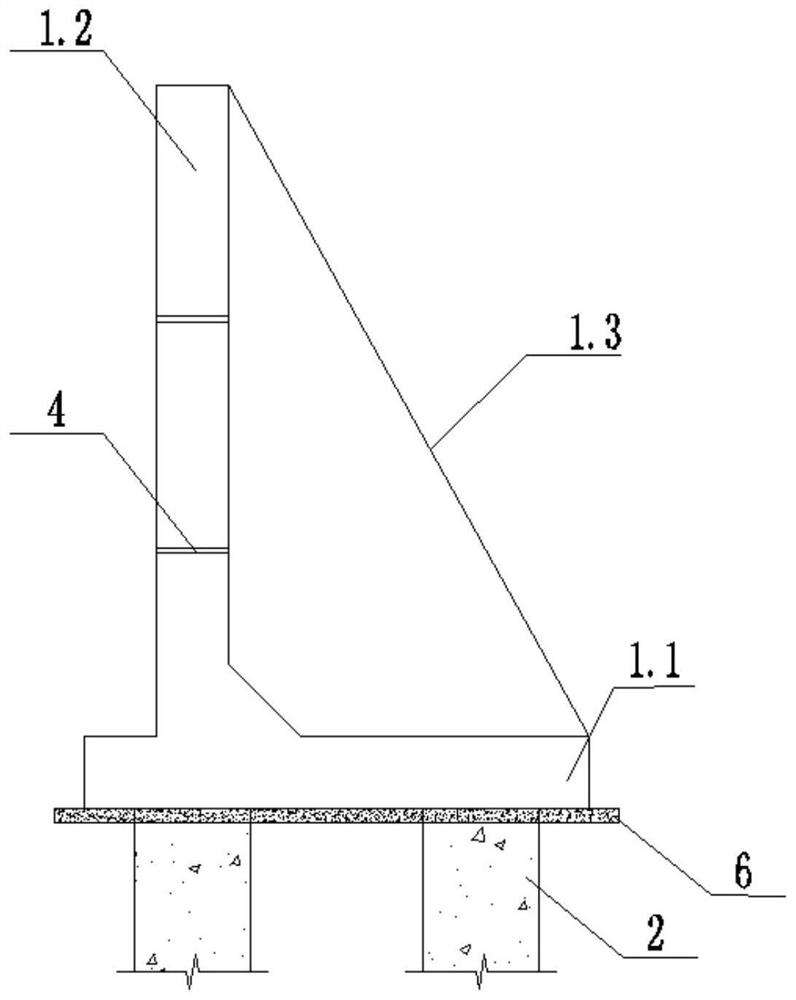

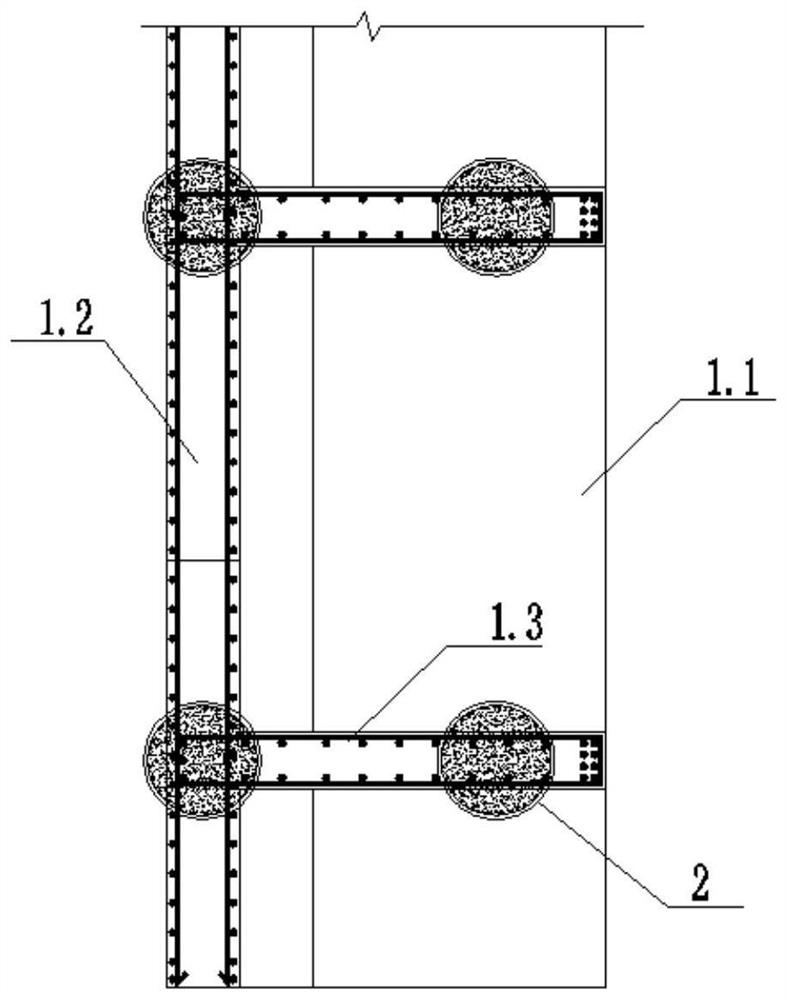

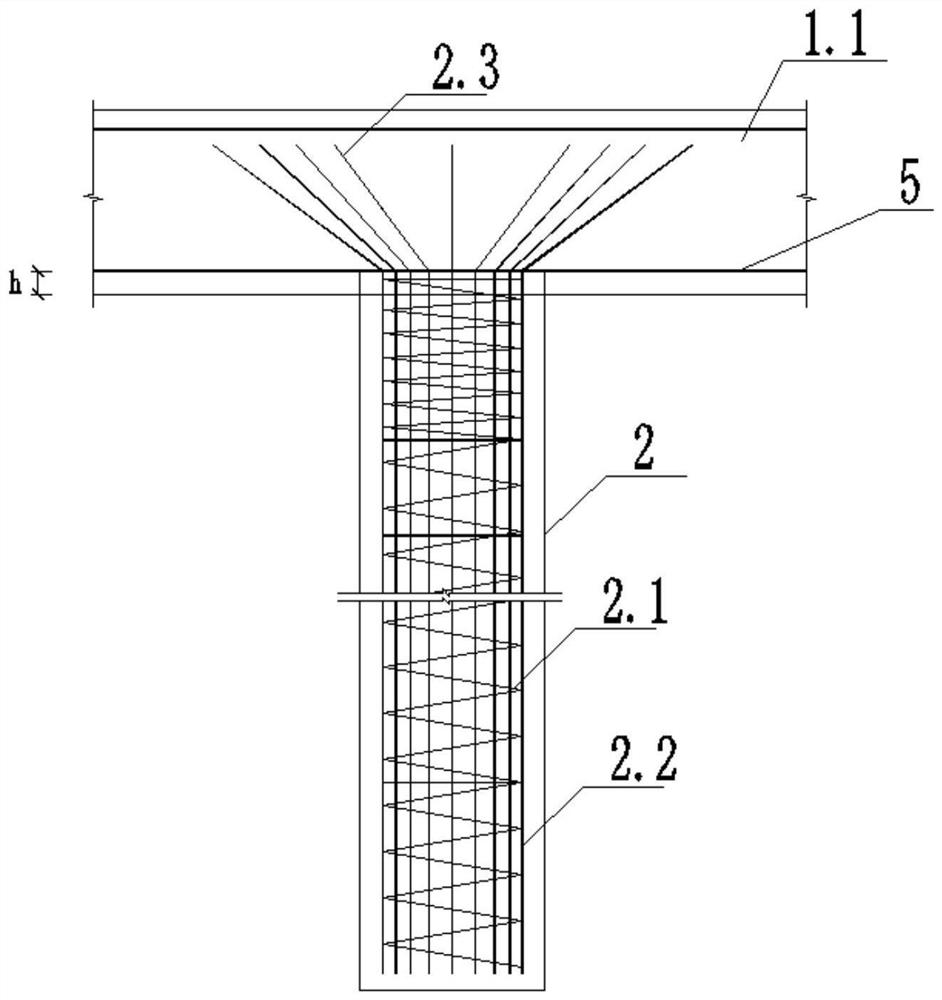

[0035] Such as Figure 1-Figure 3 As shown, the pile-supporting arm-type retaining wall of this embodiment includes a bottom plate 1.1, a vertical arm 1.2 fixed on the bottom plate 1.1, and a rib plate 1.3 for connecting the bottom plate 1.1 and the vertical arm 1.2, and the bottom of the bottom plate 1.1 is fixed. The bored cast-in-place pile 2, and the top of the bored cast-in-place pile 2 extends upwards into the bottom plate 1.1.

[0036] In this embodiment, the bored pile 2 is provided with a spiral stirrup 2.1 and a plurality of vertically arranged main reinforcements 2.2, and the spiral stirrup 2.1 spirally surrounds the main reinforcement 2.2.

[0037] In this embodiment, the upper end of the main reinforcement 2.2 extends upwards to provide an extension section 2.3, and the extension section 2.3 is arranged in the bottom plate 1.1, and the extension section 2.3 is set outwardly by the bored pile 2.

[0038] In this embodiment, the length h from the top of the bored c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com