Novel reprocessed plastic cleaning device

A technology for recycling plastics and cleaning devices, which is applied in plastic recycling and recycling technologies, etc., can solve the problems of high labor intensity of workers, and achieve the effects of easy opening, high cleanliness, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

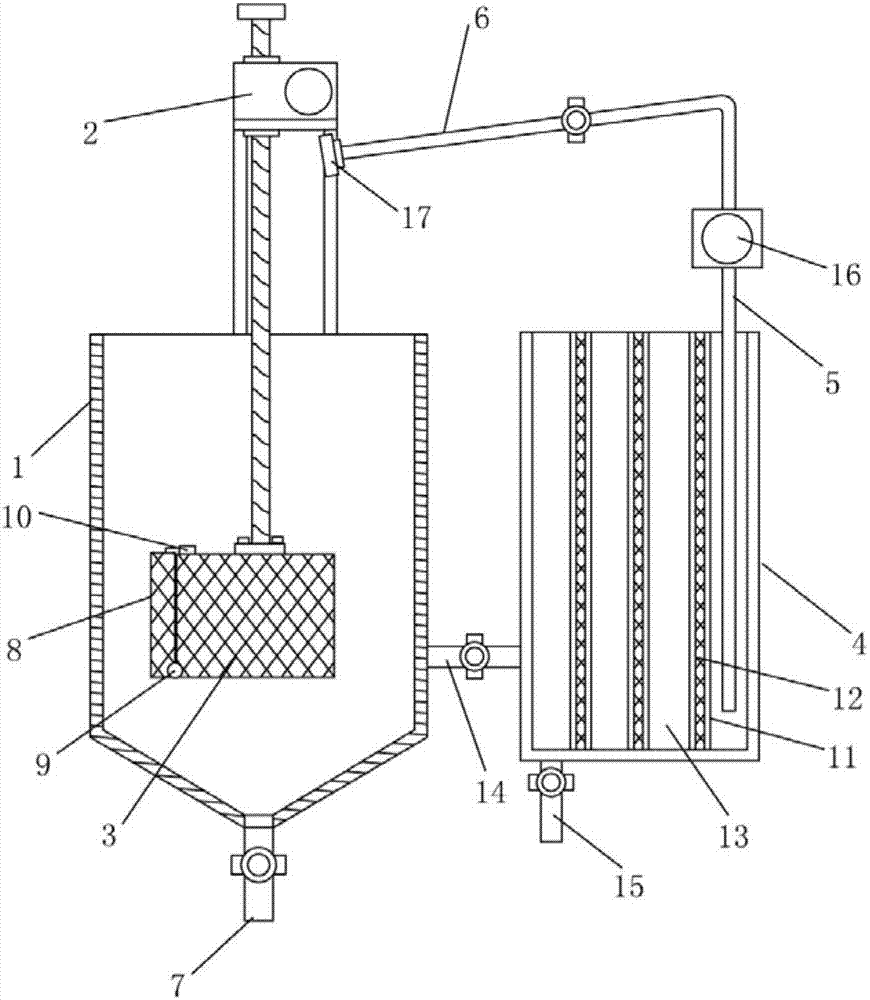

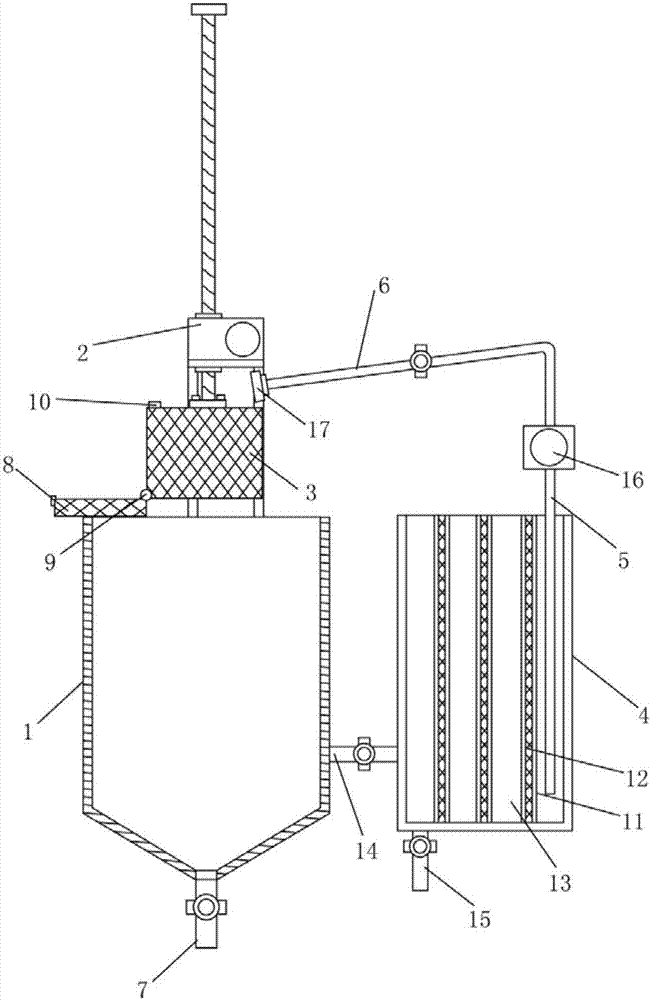

[0021] Such as Figure 1-2 As shown, a new type of recycled plastic cleaning device includes a cleaning tank 1, a lifting mechanism 2, a screen cage 3, a washing tank 4, a lower washing pipe 5, and an upper washing pipe 6. The cleaning tank 1 is a tank with an open top Structure, the bottom of the cleaning tank 1 is connected with the first sewage pipe 7, the lifting mechanism 2 is fixed on the top of the cleaning tank 1, the screen cage 3 is arranged in the cleaning tank 1 and connected with the lifting mechanism 2, one part of the screen cage 3 A cage cover 8 is arranged on the side, and the lower ends of the cage cover 8 and the screen cage 3 are hinged together by a rotating shaft 9 and the upper ends of the two are locked by a lock body 10; Road 11, three layers of slides 11 are respectively provided with a layer of filter screen 12 to separate the inside of the washing tank 4 into four cavities 13 from left to right, the leftmost cavity 13 of the washing tank 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com