Slow-cooling blowing device

A blowing device and slow cooling technology, which is applied in the structural design and application field of fiber processing devices, can solve the problems of external disturbance of filaments and affect the quality of filaments, and achieve the effects of uniform sliver, improved fiber quality, and accurate air volume control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

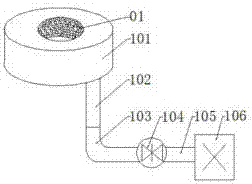

[0013] combined with figure 1 As shown, a slow cooling blowing device, the slow cooling blowing device includes an air chamber 101, an air supply channel 102 communicated with the bottom surface of the air chamber, the air supply channel 102 is connected with an air volume regulating device 104 through an air supply duct 103, The air volume adjusting device 104 is connected to the refrigerant blower 106 through the blowing pipe 105 , and a plurality of air holes 01 are evenly distributed around the inner surface of the air chamber 101 .

[0014] The bottom of the air chamber 101 can be distributed with a plurality of air supply ducts 102, and the plurality of air supply ducts 102 are distributed in a circular shape; the air chamber has a cavity structure, and the side wall of the air chamber 101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com