Veneer hot-pressing dryer

A drying machine and veneer technology, which is applied in the direction of drying machine, drying, local stirring dryer, etc., can solve the problems of poor drying effect, insufficient heating, low temperature, etc., to achieve automatic production and reduce Effect of friction force and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] EXAMPLES Single board heat press dryer

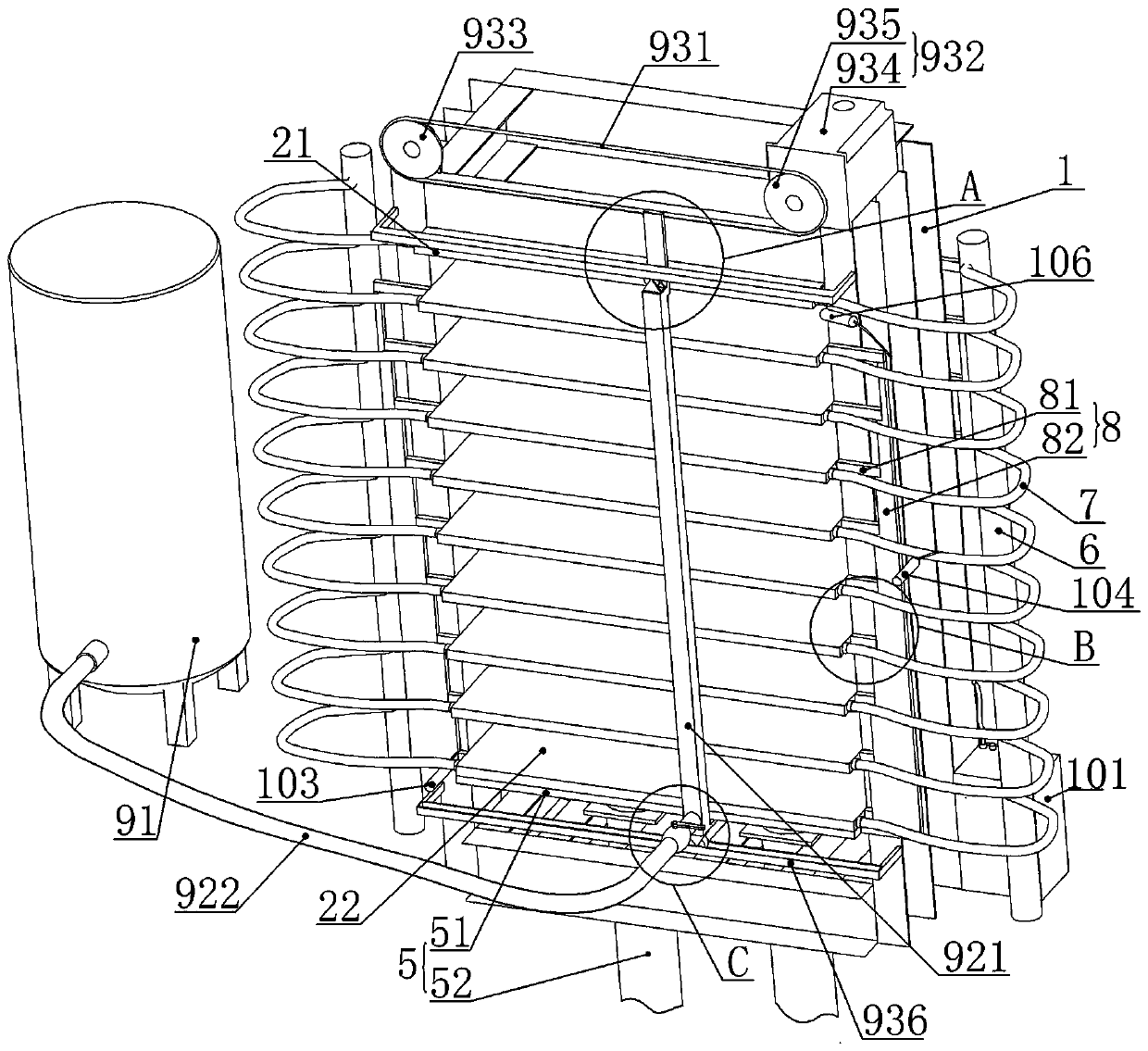

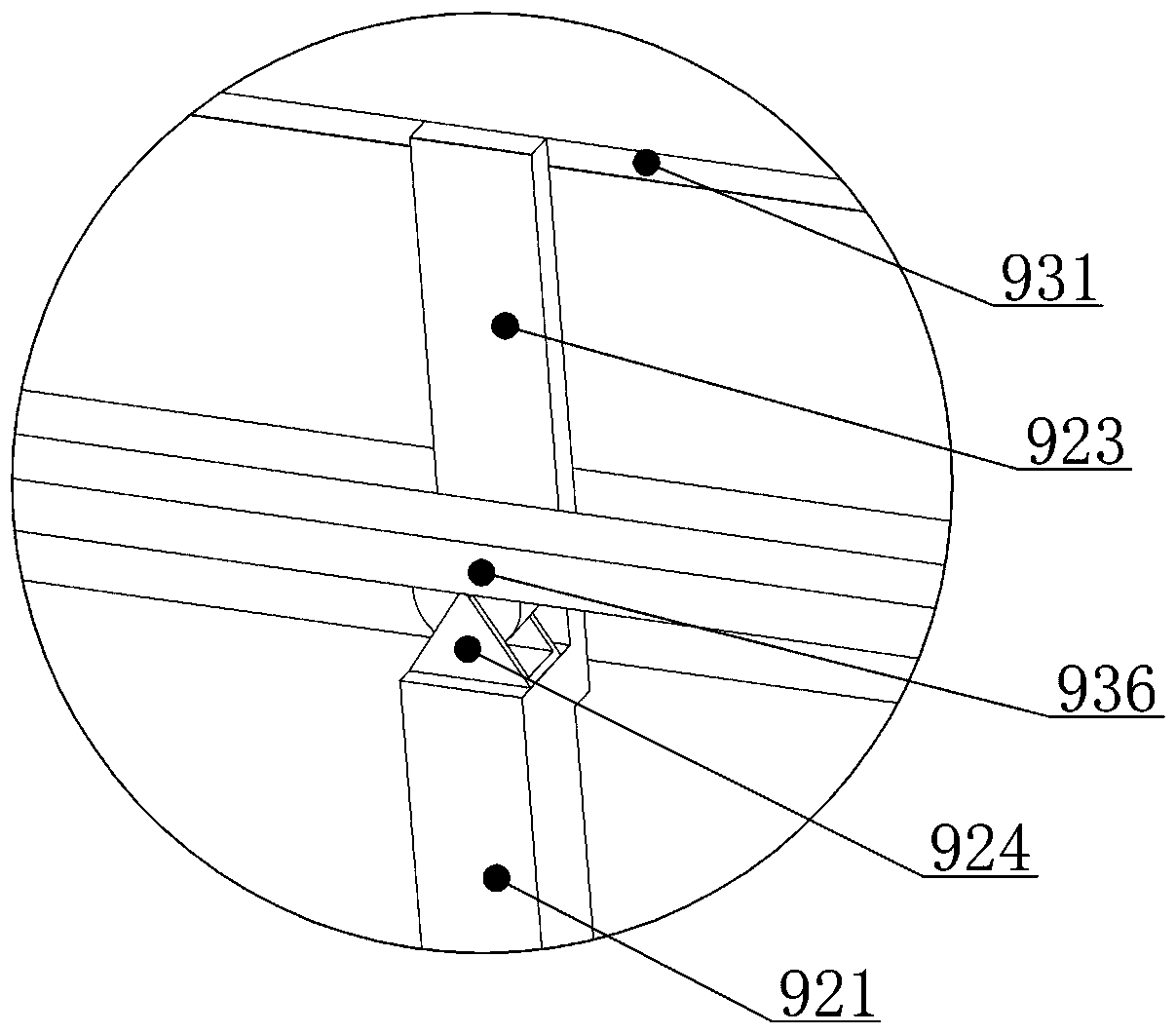

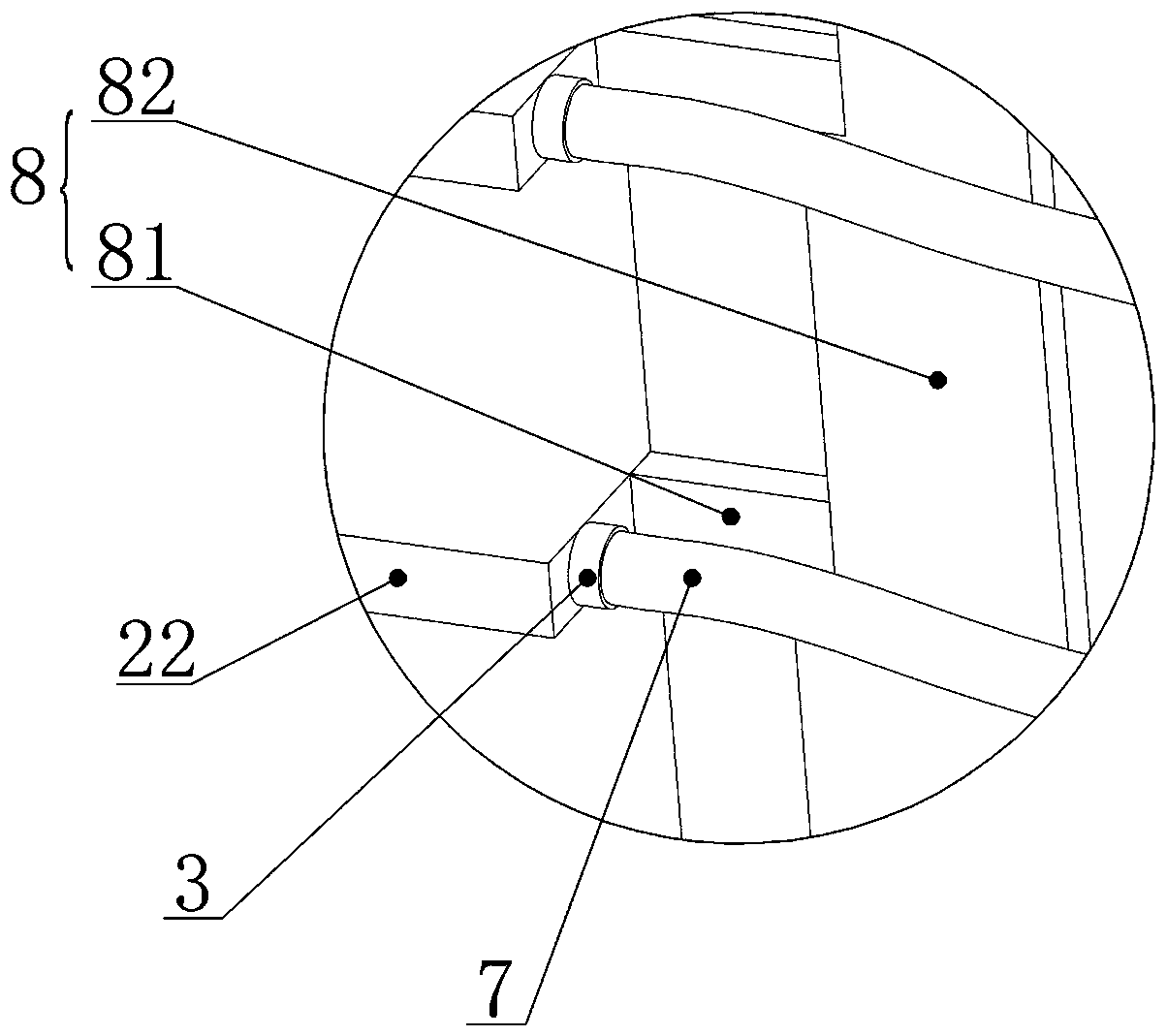

[0027] This example figure 1 — Figure 5 As shown, a veneer hot-pressing dryer includes an outer frame 1, the outer frame 1 is a rectangular parallelepiped frame made of channel steel welded, fixed on the ground, and a fixed hot plate is fixed on the top of the outer frame 1 21. Inside the outer frame 1, along the height direction of the outer frame 1, there are also nine movable thermal plates 22 that can move up and down, and an accommodation space 4 for placing a single plate is formed between two adjacent thermal plates. Plate 21 has the same structure as mobile hot plate 22, both of which are rectangular plate bodies with accommodating chambers, and hot oil is housed in the accommodating chambers, and the left and right sides of the rectangular plate body are respectively provided with a connection for connecting an external oil supply device. Mouth 3. On the outside of the left and right sides of the outer frame 1, a del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com