Construction method based on shunting separation plate bin and shunting separation plate bin device

A technology of diverting clapboards and construction methods, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of downstream water use, water pollution, construction period and cost increase, etc., to reduce construction period and cost, ensure timeliness, The effect of reducing construction cost and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

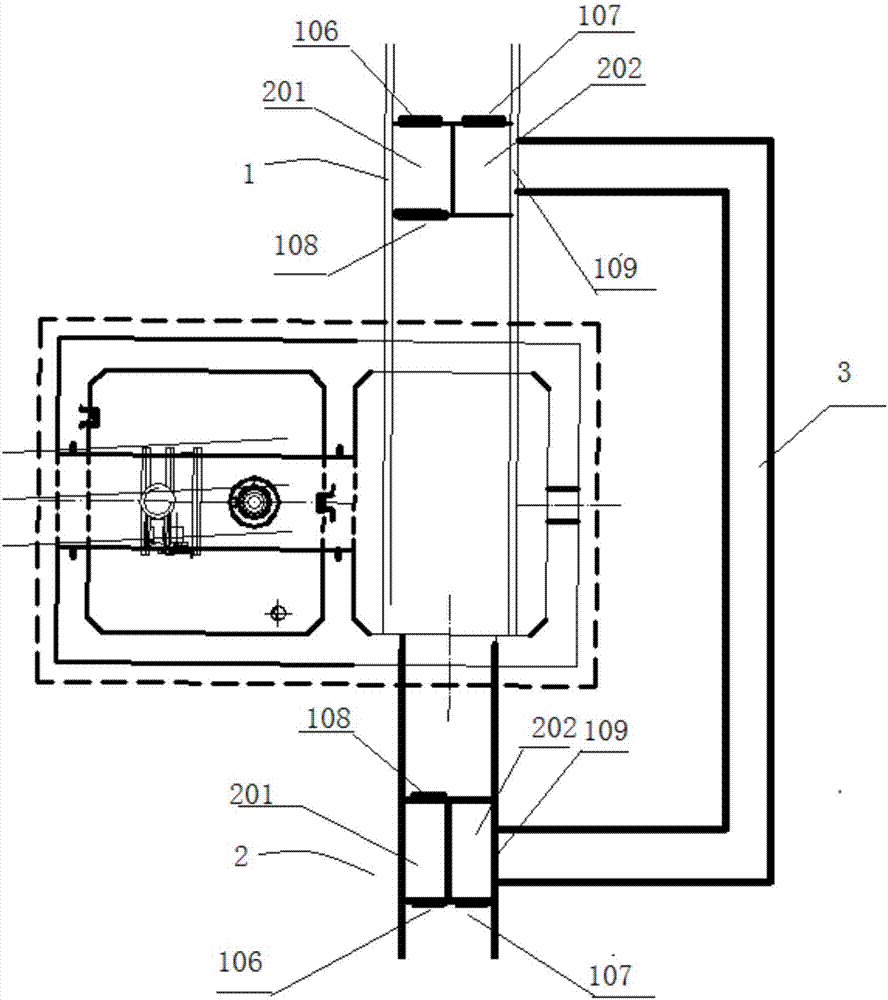

[0028] refer to Figure 1-2 As shown, the application discloses a construction method based on a diversion partition storehouse, comprising the following steps:

[0029] (1) Partition warehouse production

[0030] The steel box is processed according to the construction site and the size of the structure. The steel box is welded and combined with 2cm thick steel plates. The welded part is dense and there is no water leakage.

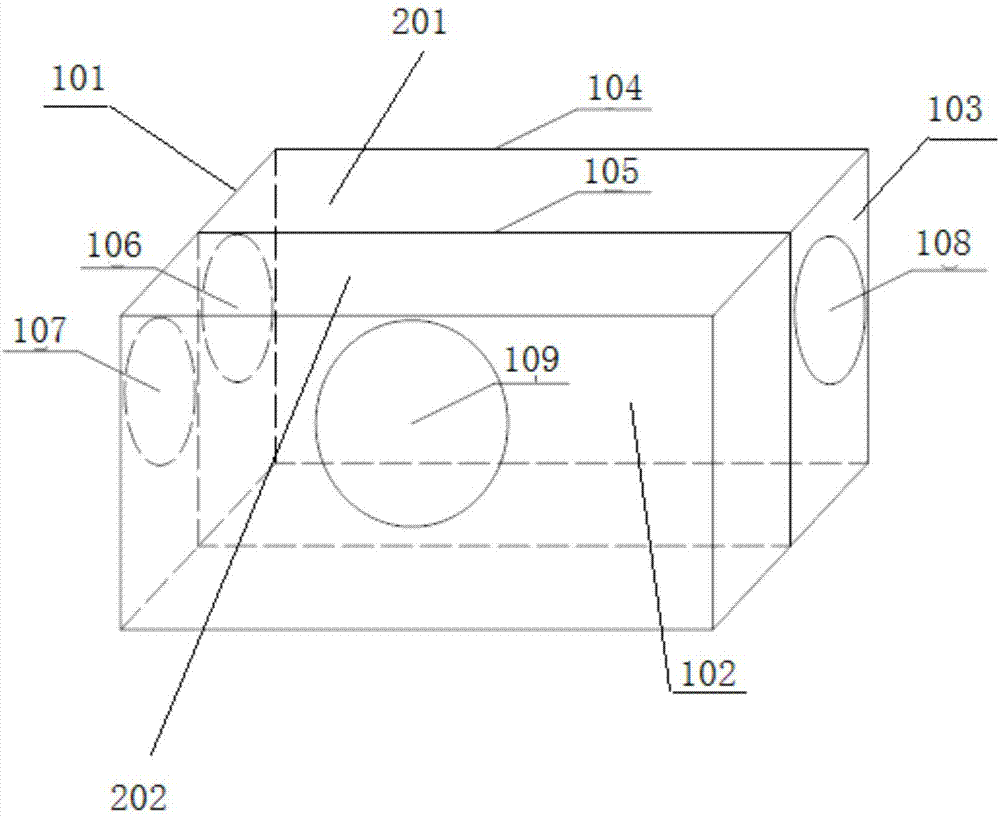

[0031] Specifically, the first steel plate 101, the second steel plate 102, the third steel plate 103, and the fourth steel plate 104 are used to form a steel box. The inside of the steel box is provided with a partition 105, and the partition 105 separates the steel box. Divided into a first chamber 201 and a second chamber 202, the top and bottom of the steel box are open, two openings are set on the first steel plate 101, and two openings are set on the second steel plate 102 and the third steel plate 103. Two openings; a first valve 106 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com