Torque limiter with unidirectional slide function

A torque limiter, one-way technology, applied in slip couplings, clutches, couplings, etc., can solve problems such as damage to generators or gearboxes, reverse torque impact, etc., and achieve the effect of protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

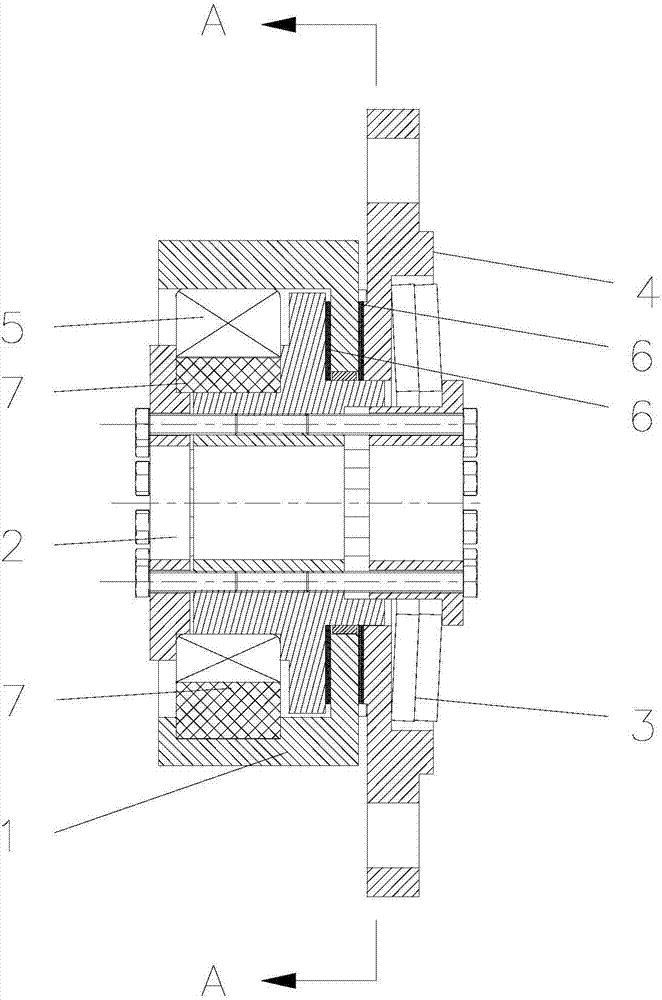

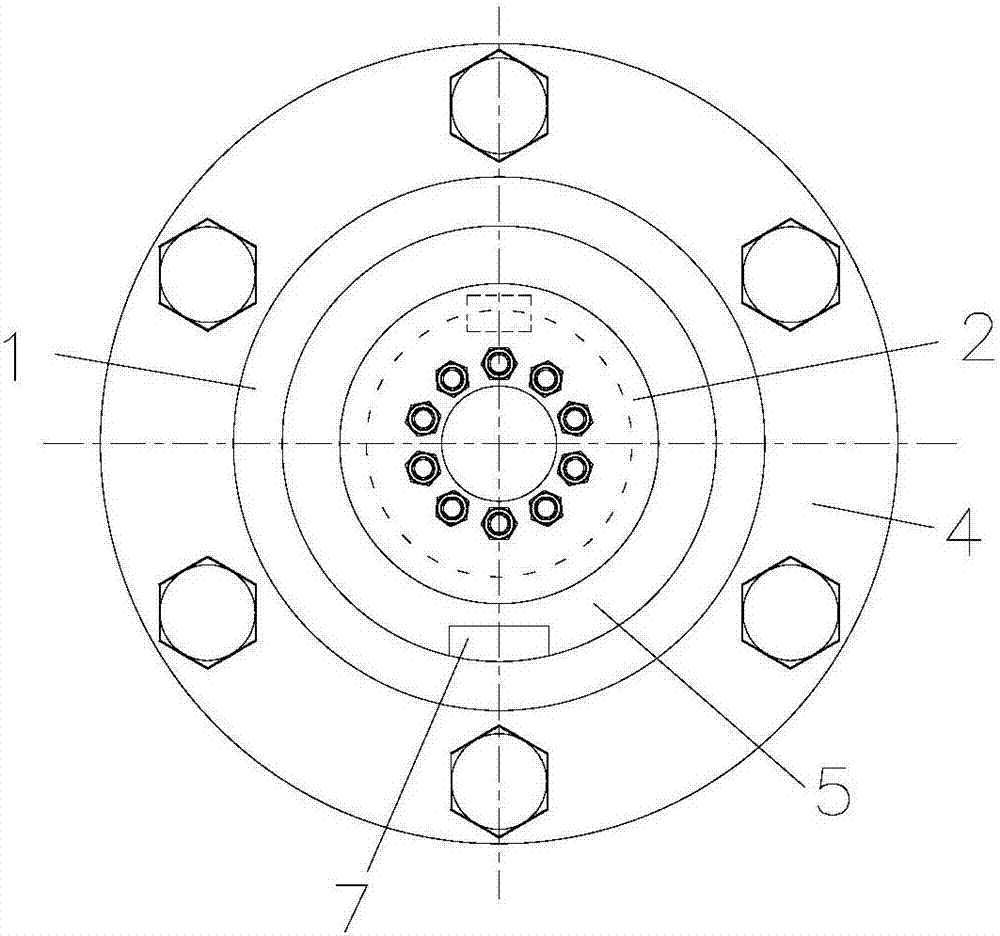

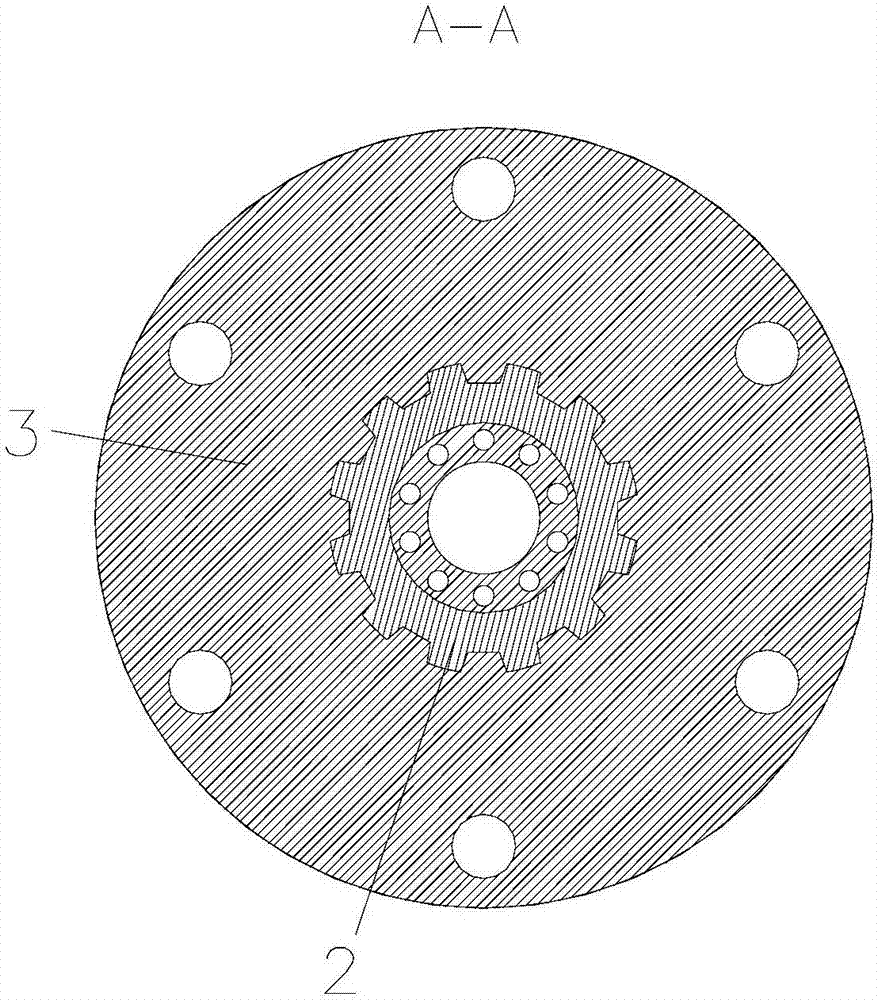

[0018] Such as figure 1 , 2 As shown in and 3, a one-way slipping torque limiter includes an input sleeve 1, an input shaft 2 and a connecting flange 4, the input shaft 2 is slidably arranged at one end of the connecting flange 4 along its axial direction, and the The input shaft 2 is provided with a limit mechanism for limiting the radial displacement of the connecting flange 4, and a spring 3 is arranged between the connecting flange 4 and the input shaft 2, and the springs 3 are butterfly springs 3 , the input sleeve 1 is located between the input shaft 2 and the connecting flange 4, the contact surface between the input sleeve 1 and the input shaft 2 and the contact surface between the input sleeve 1 and the connecting flange 4 are all frictionally connected, A backstop 5 is fixedly connected between the input sleeve 1 and the input shaft 2 .

[0019] The limiting mechanism includes a spline groove arranged on the input shaft 2, and the connecting flange 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com