Sealing device for heat and tail parts of air bellow of metallurgic sintering machine

A sealing device and sintering machine technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., to achieve the effect of improving output and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

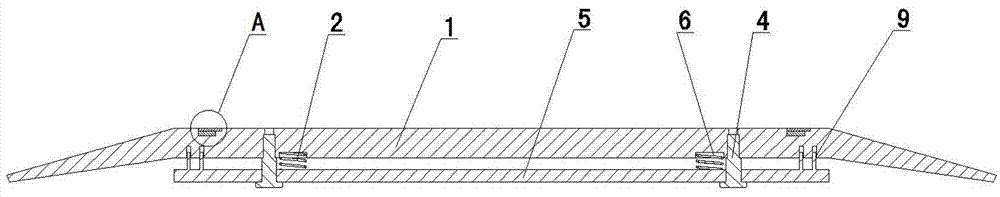

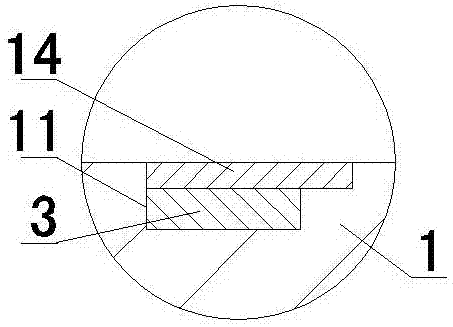

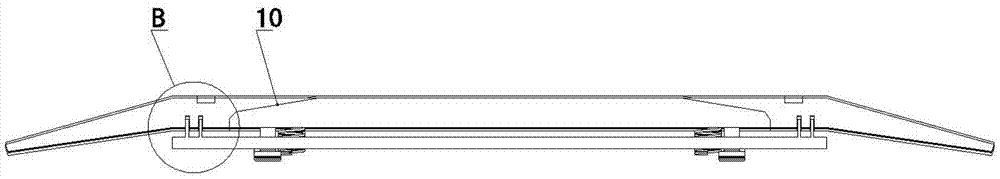

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a sealing device for the head and the tail of a bellows of a metallurgical sintering machine, including several key-type sealing plates 1 arranged on the lower surface of the trolley beam 7, the lower end of the key-type sealing plates 1 is provided with a spring installation groove 6, and each key The bottom of the type sealing plate 1 is connected with the bottom plate 5 through the guide positioning pin 4, and the high temperature resistant spring 2 forming the top pressure is arranged between the spring installation groove 6 and the bottom plate 5. When the trolley beam 7 moving on the key type sealing plate 1 When the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com