High-pressure leakage detection equipment of finned heat exchanger

A finned heat exchanger and high-pressure technology, which is applied in the testing of instruments, machines/structural components, and by measuring the rate of increase and deceleration of fluids, etc., can solve the problem of gas waste, difficulty in ensuring detection accuracy, and unsatisfactory leak detection equipment. High-voltage test requirements and other issues, to achieve the effect of high safety factor, improve accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

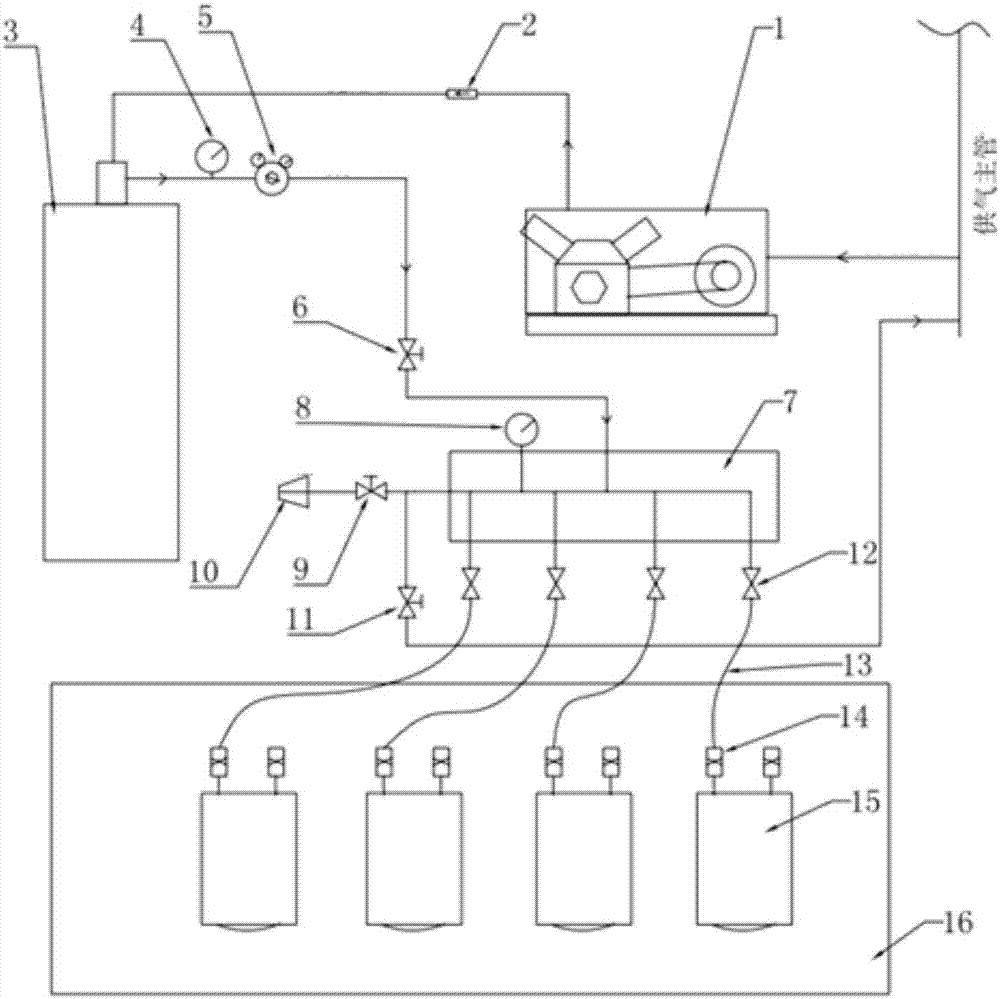

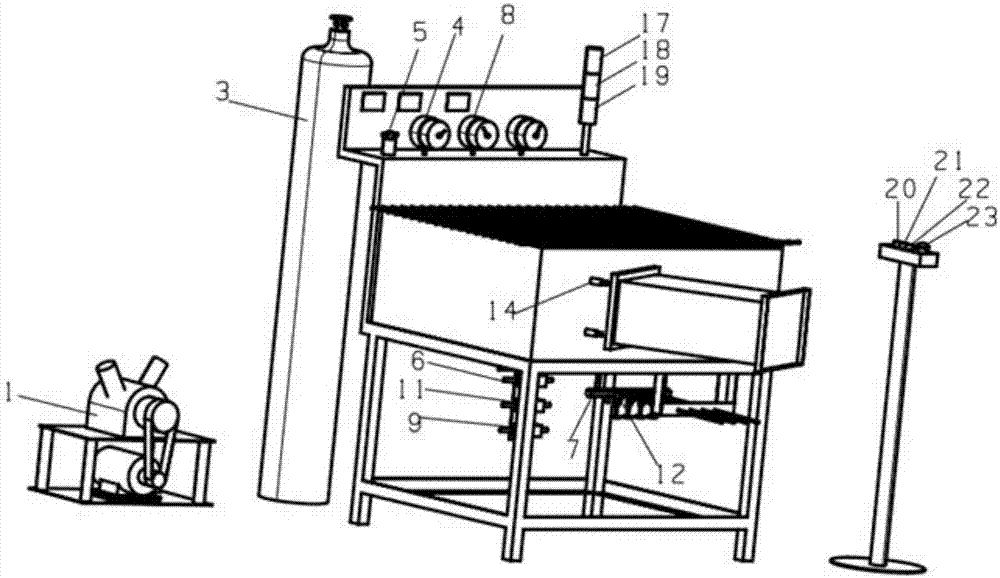

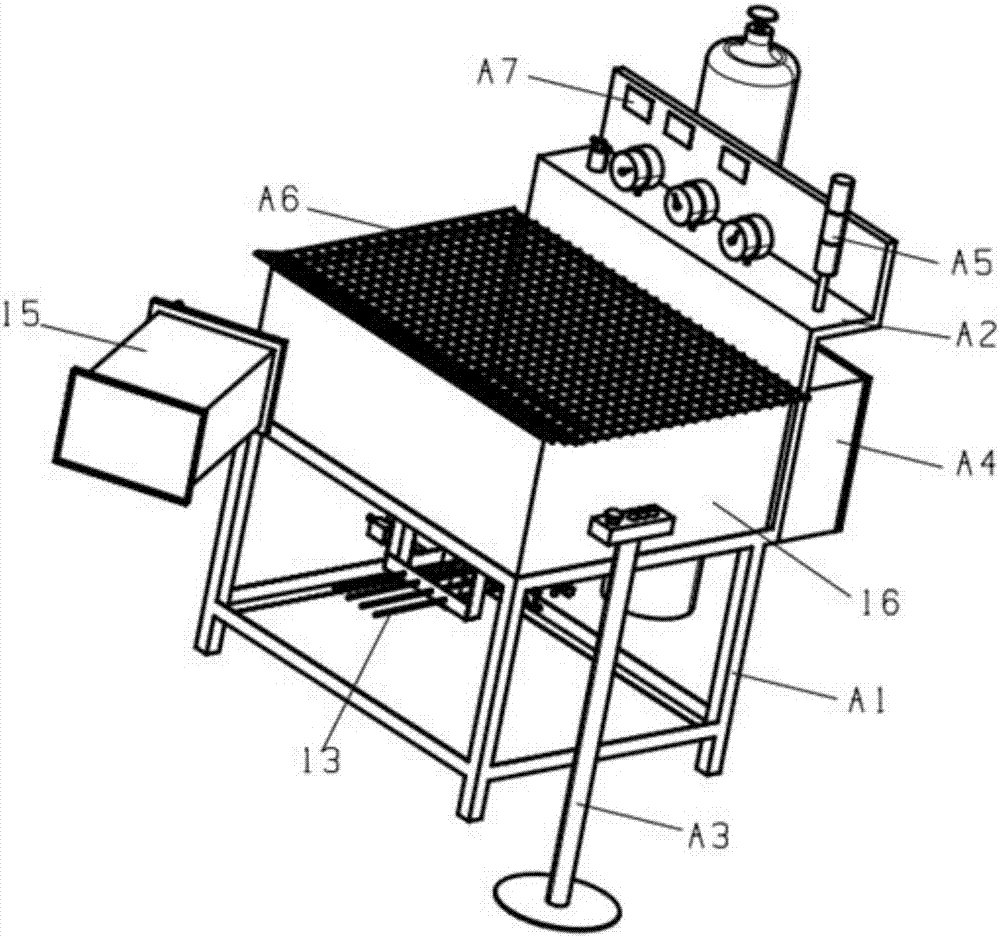

[0023] Such as figure 1 , 2 . The high-pressure leak detection equipment for the fin heat exchanger shown in 3 includes a supercharger 1, a high-pressure gas storage tank 3, a pressure reducer 5, a seven-way piece 7, a water tank 16 and an electric control unit, and the seven-way piece 7 is on There is an air inlet, an exhaust port, a pressure measuring port and four test ports. The supercharger 1 is connected to the main air supply pipeline through a pipeline, and the air outlet of the supercharger 1 is connected to the high-pressure The gas storage tank 3 is connected by a pipeline, and the air inlet of the high-pressure gas storage tank 3 and the seven-way piece 7 is connected by a pipeline, and the first electric contact pressure gauge 4, the pressure reducer 5 and the first electric contact pressure gauge 4 are arranged in sequence on the connecting pipeline. A solenoid valve 6; the test port of the seven-way part 7 is connected to one port of the heat exchanger 15 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com