A preparation method of rare earth hexaboride field emission array

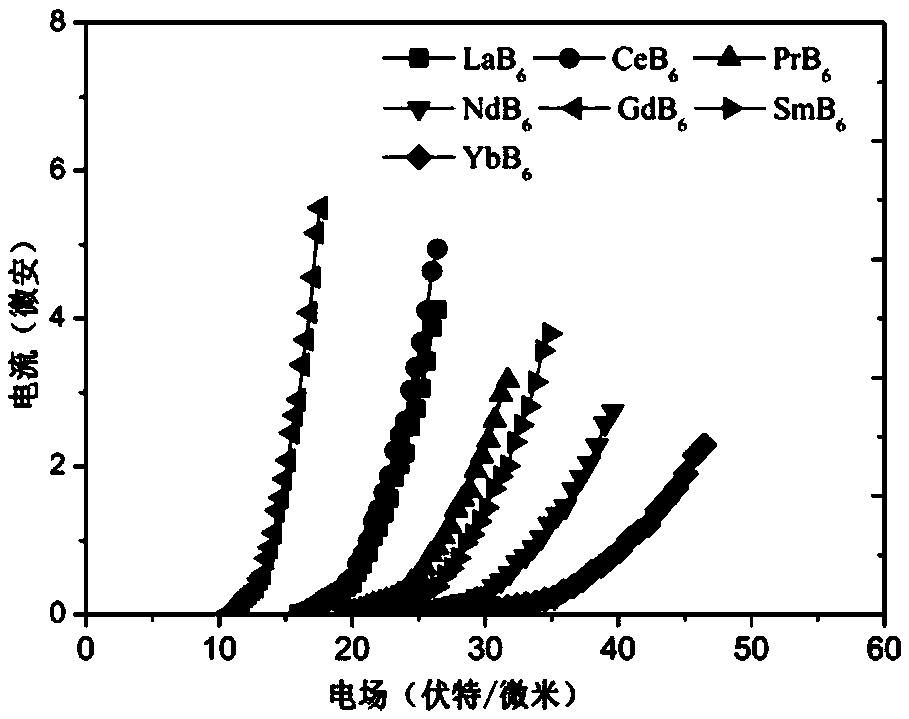

An emission array and hexaboride technology, applied in the field of field emission array micromachining, can solve the problems of application limitation, micromachining difficulty, material processing, etc., and achieve the effect of large number density and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) The bulk LaB 6 The surface is mechanically polished;

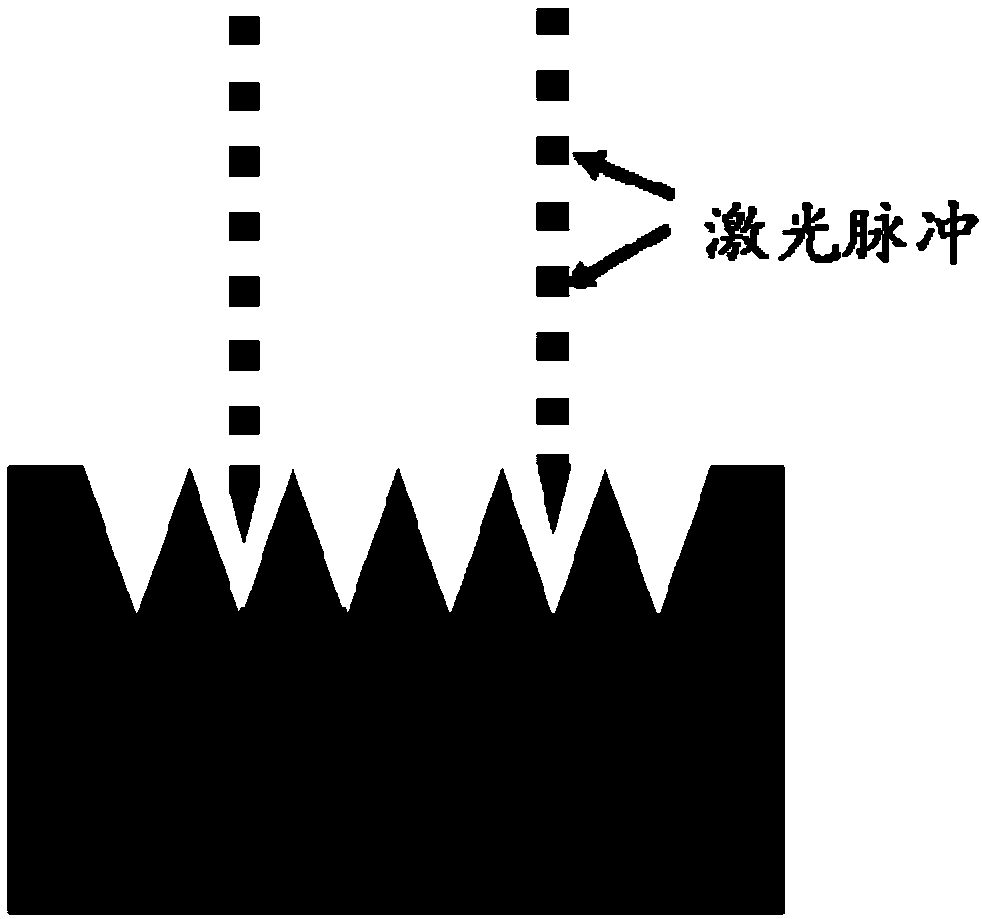

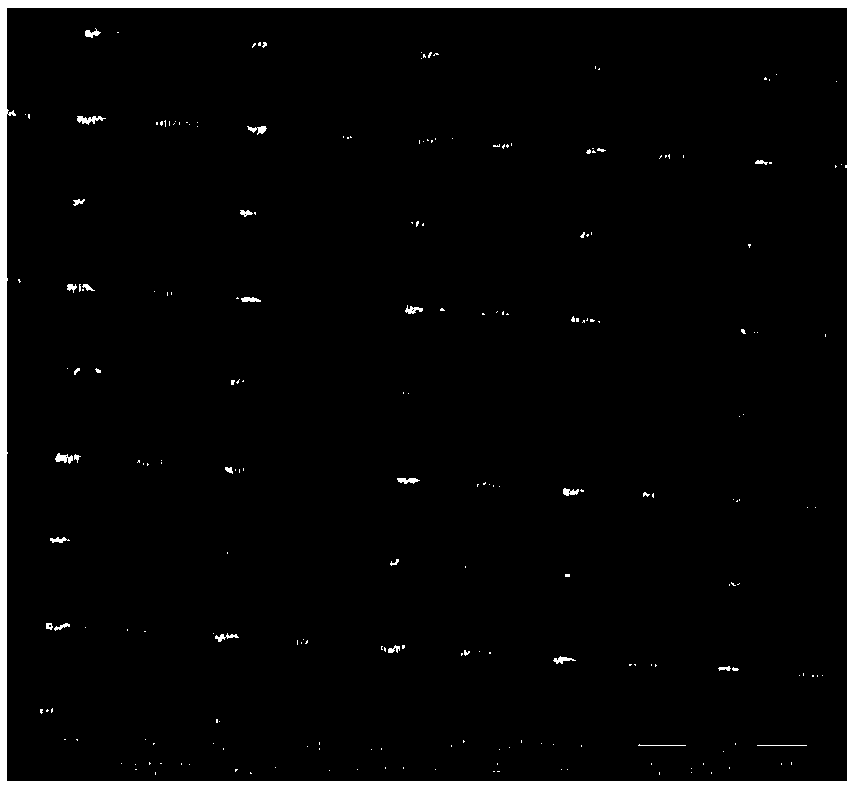

[0017] 2) Femtosecond laser micro-nano processing equipment is used, and the high-energy laser beam generated by it is used to step-polish the LaB 6 The surface is removed by laser direct writing, and the processed array density is 10,000 pieces / mm 2 ;

[0018] 3) Using femtosecond laser micro-nano processing technology to process LaB 6 When performing direct writing removal, the specific processing parameters are: under the condition of positive focus, the laser energy density is about 100J / cm 2 ;The speed of laser direct writing is 20.0mm / min; the number of equivalent pulses of laser is 50 / min; the interval of laser direct writing is 10.0μm;

Embodiment 2

[0020] 1) The bulk CeB 6 The surface is mechanically polished;

[0021] 2) Femtosecond laser micro-nano processing equipment is used, and the high-energy laser beam generated by it is used to step-polish the CeB 6 The surface is removed by laser direct writing, and the processed array density is 100,000 pieces / mm 2 ;

[0022] 3) Using femtosecond laser micro-nano processing technology to process CeB 6 When performing direct writing removal, the specific processing parameters are: under the condition of positive focus, the laser energy density is about 80J / cm 2 ;The speed of laser direct writing is 40.0mm / min; the number of equivalent pulses of laser is 100 / min; the interval of laser direct writing is 2.0μm;

Embodiment 3

[0024] 1) The bulk PrB 6 The surface is mechanically polished;

[0025] 2) Femtosecond laser micro-nano processing equipment is used, and the high-energy laser beam generated by it is used to step-polish the PrB 6 The surface is removed by laser direct writing, and the processed array density is 50,000 pieces / mm 2 ;

[0026] 3) Using femtosecond laser micro-nano processing technology to process PrB 6 When performing direct writing removal, the specific processing parameters are: under the condition of positive focus, the laser energy density is about 70J / cm 2 ;The speed of laser direct writing is 50.0mm / min; the number of equivalent pulses of laser is 150 / min; the interval of laser direct writing is 4.0μm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com