Cathode pole piece, preparation method thereof, and lithium ion battery

A cathode and pole piece technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc. Can not protect the cathode active material and other problems, to achieve the effect of improving electrochemical performance, strong operability, and good uniformity of film formation and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

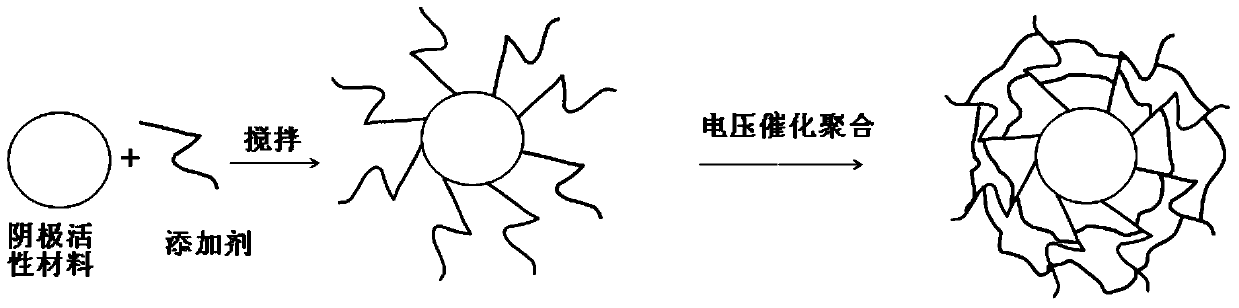

[0045] Next, the preparation method of the cathode electrode sheet according to the second aspect of the present invention is described, which is used to prepare the cathode electrode sheet described in the first aspect of the present invention, including the steps of: uniformly mixing the conductive agent, the binder and the solvent to obtain a conductive agent solution ; After stirring and mixing the additive and the cathode active material, add the conductive agent solution, stir evenly to obtain the cathode slurry, then place the cathode slurry on the cathode current collector, and obtain the cathode electrode sheet after drying, wherein the cathode slurry is dried After removing the solvent, a cathode active material layer is formed.

[0046] The conventional mixing process is to add cathode active materials, conductive agents, binders, additives, solvents, etc. into the mixing tank in sequence, and stir them together to make cathode stirring materials, which cannot ensure...

Embodiment 1

[0054] (1) Preparation of additives

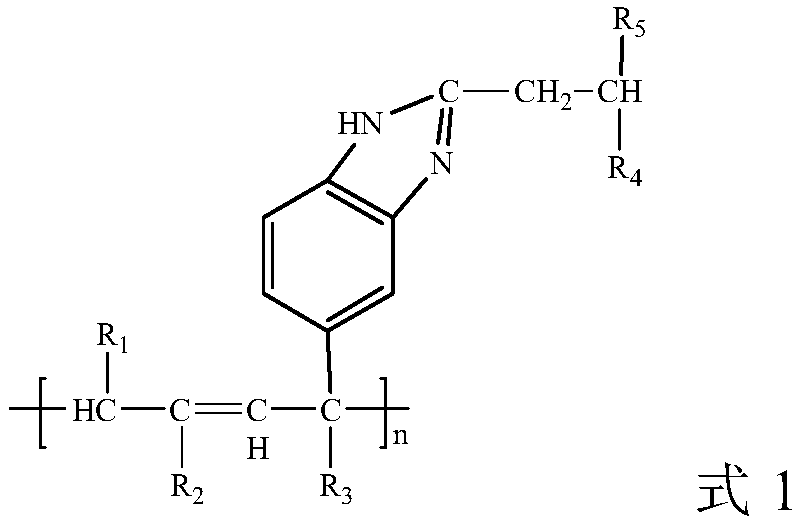

[0055] The molecular structure of the additive is as follows:

[0056]

[0057]

[0058] Prepare the Grignard reagent by reacting monomer 1 and Mg in anhydrous ether environment, then add the monomer 2 mixed with KOH into the Grignard reagent dropwise, and react for 1.5h at 30°C under the protection of nitrogen. ~2h, the monomer before polymerization was obtained. Then transfer the monomer before polymerization to another reaction vessel, using AlEt 3 / NiOct / BF 3 ·Et 2 O catalyst system, using benzene as a solvent, reacting at 40°C to 55°C for 2 hours to obtain the additive represented by formula I. In formula I, the degree of polymerization n is 15-20.

[0059] (2) Preparation of cathode sheet

[0060] The cathode active material lithium cobalt oxide (LiCoO 2 ), the additive shown in formula I, and the solvent N-methylpyrrolidone (NMP) were mixed and stirred for 2 hours, then the conductive agent solution composed of conducti...

Embodiment 2

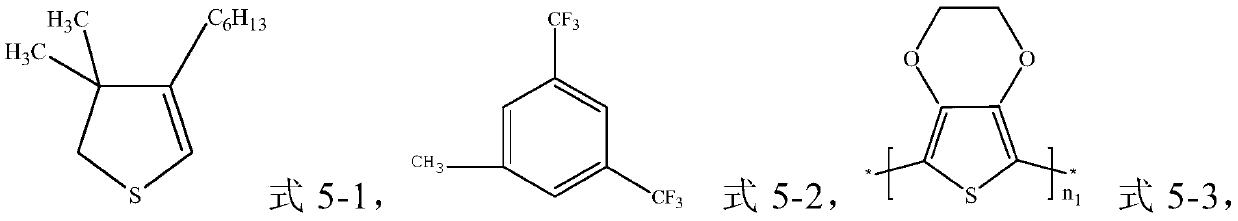

[0068] A lithium-ion battery was prepared according to the method of Example 1. The difference is that the molecular structure of the additive is as follows:

[0069]

[0070]

[0071] Prepare the Grignard reagent by reacting monomer 1 and Mg in anhydrous ether environment, then add the monomer 2 mixed with KOH into the Grignard reagent dropwise, and react for 1.5h at 30°C under the protection of nitrogen. ~2h, the monomer before polymerization was obtained. Then transfer the monomer before polymerization to another reaction vessel, using AlEt 3 / NiOct / BF 3 ·Et 2 O catalyst system, using benzene as a solvent, reacting at 40° C. to 55° C. for 2 hours to obtain the additive represented by formula II. In formula II, the degree of polymerization n is 15-20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com