Automatic assembly device for the rubber sleeve at the end of the wire

An automatic assembly and rubber sleeve technology, applied in the assembly/disassembly of contact parts, etc., can solve the problems of using large force, time-consuming and laborious, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

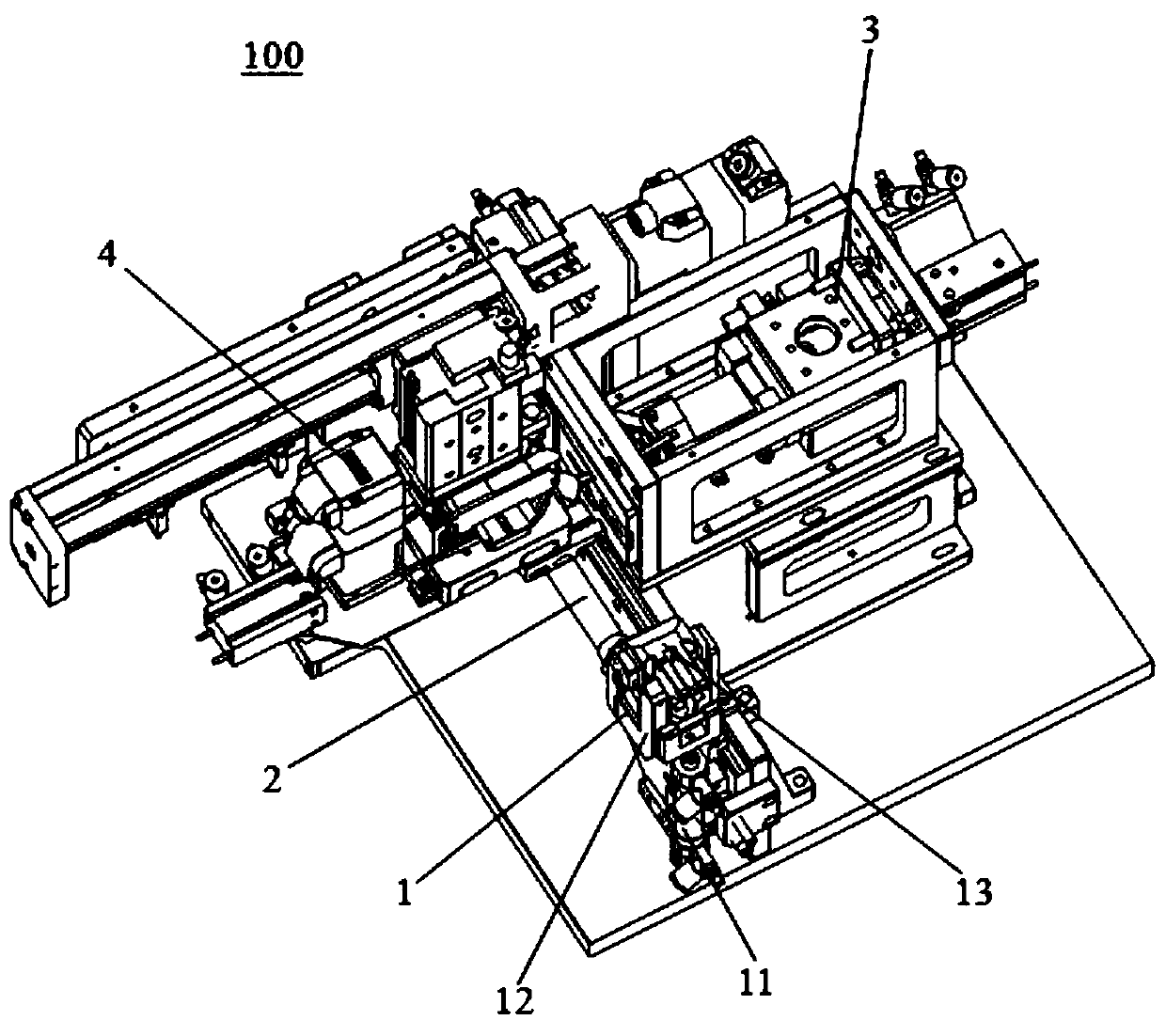

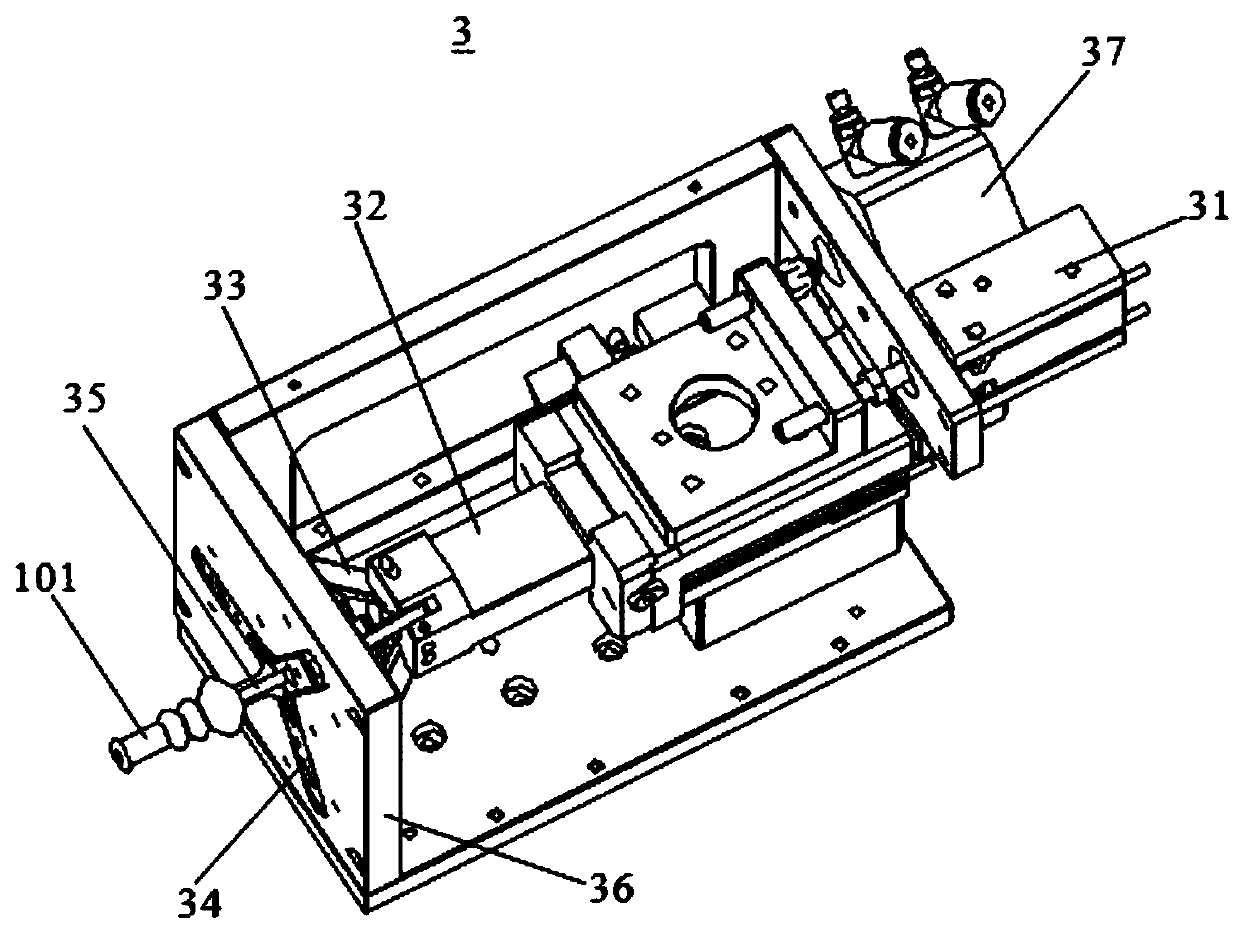

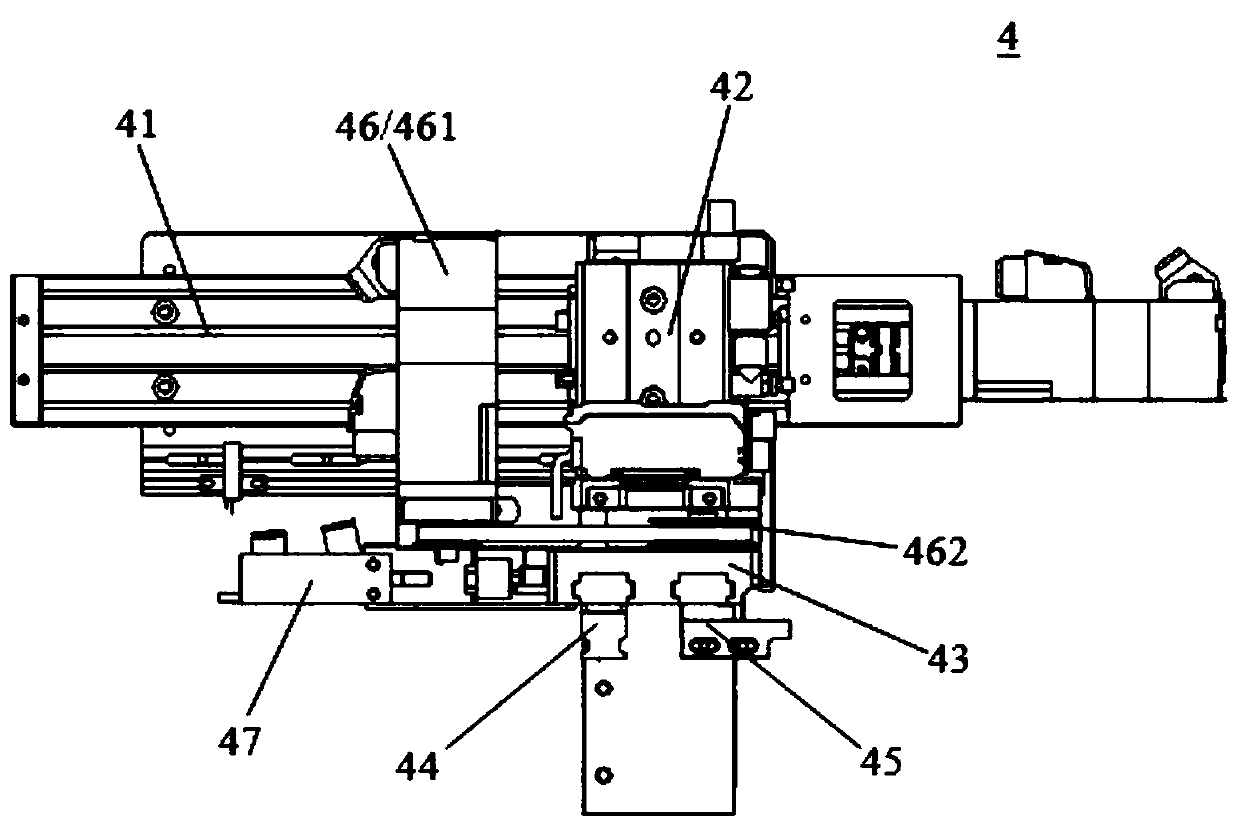

[0024] Please refer to Figure 1-Figure 3 , the present embodiment is an automatic assembly device 100 for the rubber sleeve at the end of the wire, which includes a first clamping device 1 for clamping the rubber sleeve, a first cylinder 2 for driving the first clamping device 1 to move left and right, and stretching the rubber sleeve The expansion device 3, the second cylinder (not shown in the figure) that drives the expansion device 3 to move back and forth, and the push-in device 4 that clamps and pushes the wire into the rubber sleeve.

[0025] The first clamping device 1 includes a third air cylinder 11 , a bearing claw 12 carrying a rubber sleeve, and a capping claw 13 driven by the third cylinder 11 to open or engage with the bearing claw 12 . The middle part of the capping claw 13 is hinged on the bearing claw 12 through a rotating shaft, and the other end of the capping claw 13 is hinged together with the movable end of the third cylinder 11 through a pin shaft. Dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com