Mechanically-pumping compressed gas foam fire-extinguishing method

A compressed gas and foam fire extinguishing technology, applied in fire rescue and other directions, can solve the problems of complex control system, inaccurate measurement of mixing ratio, high energy consumption, etc., and achieve the effects of accurate mixing ratio, easy operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

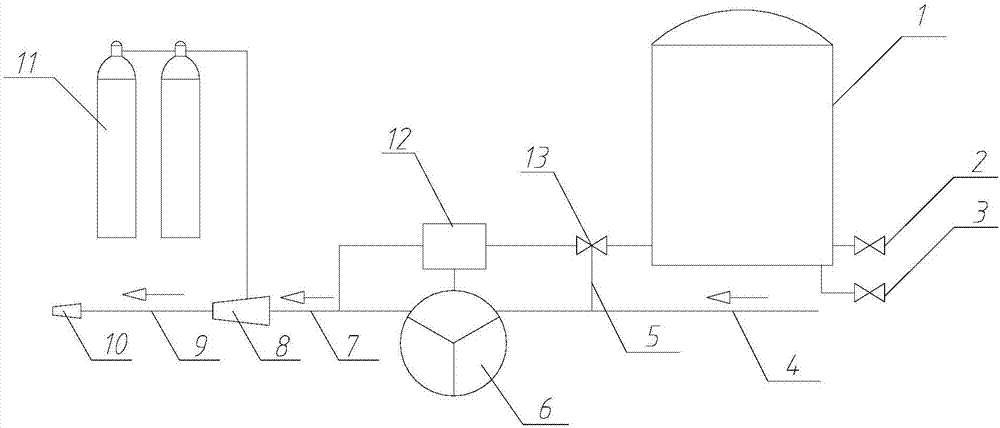

[0015] like figure 1 As shown, a mechanically pumped compressed gas foam fire extinguishing method includes an atmospheric pressure foam liquid storage tank, a filling port, a discharge port, a fire pressure water source, a flushing and debugging pipeline, a water turbine, a foam generator, a foam delivery pipeline, and a foam spray gun , foam liquid pump, water-foam liquid selection valve, the lower part of the normal-pressure foam liquid storage tank is provided with a filling port, a discharge port, a water-foam liquid selection valve, and the water-foam liquid selection valve is connected with the flushing debugging pipeline and the foam liquid pump , the water turbine is connected with the foam liquid pump and the fire pressure water source, the outlet of the water turbine is mixed with the outlet pipeline of the foam liquid pump and then connected with the inlet of the foam generator, and the outlet of the foam generator is connected with the foam spray gun through the fo...

Embodiment 2

[0021] at 10m 3 The raw liquid storage tank is filled with 3% foam fire extinguishing agent, the inlet and outlet diameters of the foam proportional mixer and the foam generator are both DN200, and the compressed gas is composed of a group of 40L compressed air cylinders with a pressure of 10MPa, which are collected after decompression flow tube.

[0022] The 3% foam fire extinguishing agent enters the raw liquid storage tank 1 from the filling port 2, starts the water supply pump, and the water from the fire-fighting pressure water source 4 enters the water turbine 6, and the water turbine 6 drives the foam liquid pump 12 to rotate, and the water-foam liquid selection valve 13 is opened. When the foam liquid is opened, the fire extinguishing agent enters the foam liquid pump 12. Driven by the water turbine 6, the fire extinguishing agent mixes with water and enters the foam generator 8. The air source 11 is turned on and collected in the collecting pipe after being decompress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com