A method of color 3D printing compatible with monochrome 3D printing

A 3D printing, color technology, applied in the field of 3D printing, can solve the problem of non-existence, achieve the effect of saving dyes and expanding the types of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

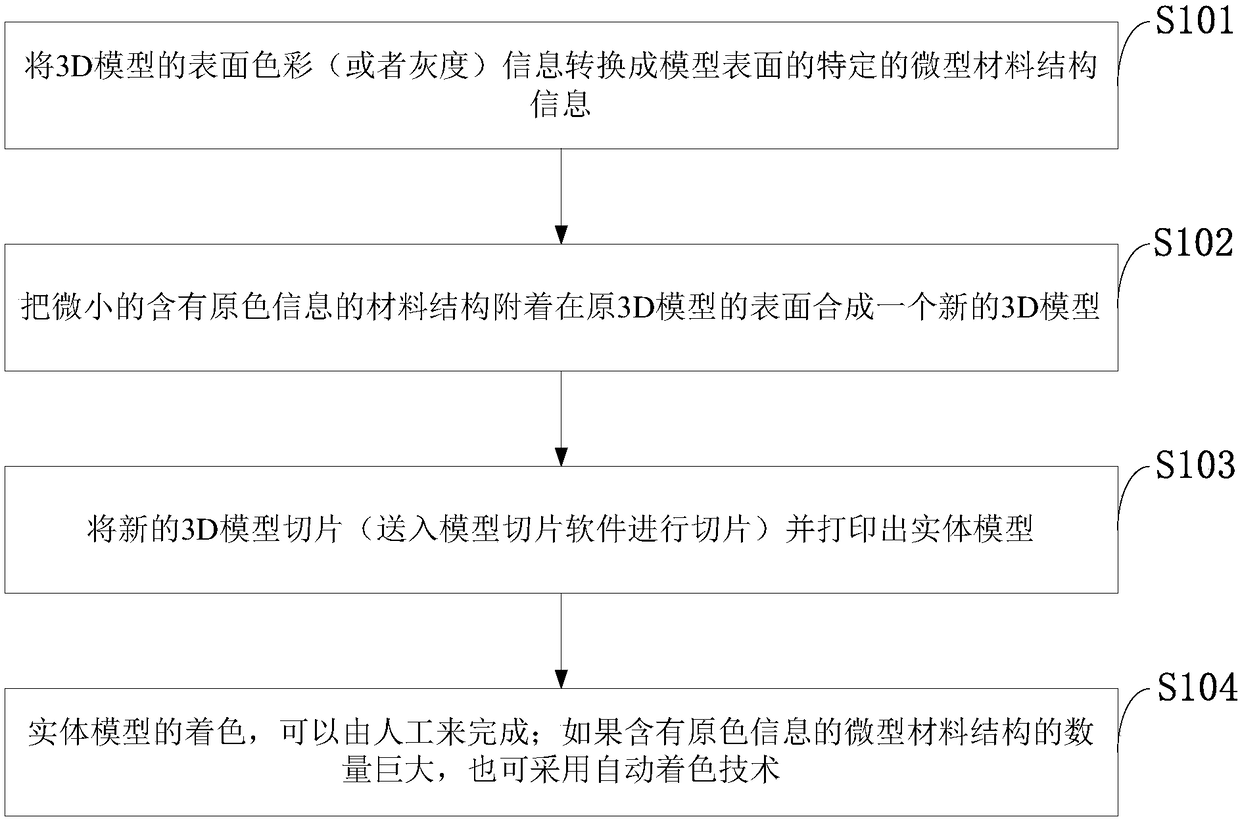

[0030] Example 1: Compatible monochrome 3D printing is upgraded to color 3D printing:

[0031] The printing material is white, including the following steps:

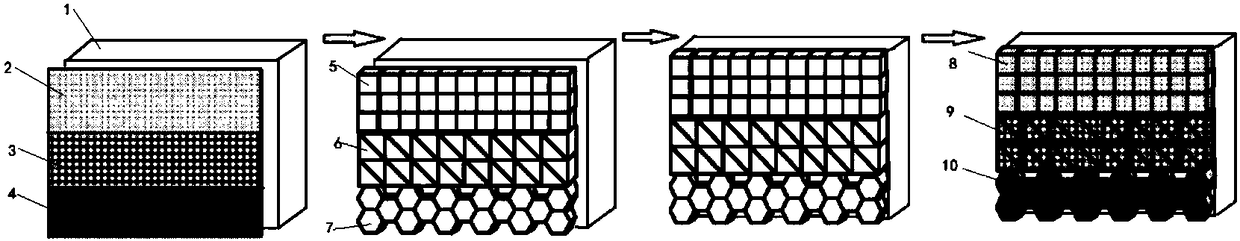

[0032] ①Convert the surface color information of the 3D model into three primary colors of yellow, cyan (Cyan), and magenta (Magenta). The three primary colors correspond to three different material structures. For example, yellow corresponds to a regular quadrilateral material structure, cyan corresponds to a regular triangular material structure, and magenta corresponds to a regular hexagonal material structure (because the printing material is white, the material structure corresponding to white information can be any default material structure. In the subtractive color representation system In , adding white to a color does not change its hue, it only reduces the saturation of the color)

[0033] ② Attach these tiny material structures containing primary color information to the surface of the original 3D model to...

Embodiment 2

[0037] Embodiment 2: An example of upgrading from monochrome 3D printing to color 3D printing:

[0038] The printing material is white, including the following steps:

[0039] ①Convert the surface color information of the 3D model into "CMYK color space", which is a color system composed of cyan (C), magenta (M), yellow (Y) and black (K). Four primary colors. These four primary colors correspond to four different material structures. For example, cyan corresponds to a regular quadrilateral material structure, magenta corresponds to a regular triangular material structure, and yellow corresponds to a regular pentagonal material structure. Black corresponds to the regular hexagonal material structure (since the printing material is white, the material structure corresponding to the white information can be any default material structure. In the subtractive color representation system, adding white to a color will not change its hue, only decrease the saturation of the color) ...

Embodiment 3

[0043] Embodiment 3: a kind of automatic coloring implementation case:

[0044] The printing material is white, including the following steps:

[0045] ①Convert the surface color information of the 3D model into three primary colors of yellow, cyan (Cyan), and magenta (Magenta). The three primary colors correspond to three different specific material structures. Yellow corresponds to the material structure of hemispherical pits with a diameter of 0.20-0.25mm, cyan corresponds to the material structure of hemispherical pits with a diameter of 0.30-0.35mm, and magenta corresponds to the material structure of hemispherical pits with a diameter of 0.40-0.45mm. In addition, three coloring containers are provided, and three spherical primary color particles of yellow, cyan, and magenta are respectively placed in the containers, and the diameters are 0.20-0.25mm, 0.30-0.35mm, and 0.40-0.45mm respectively.

[0046]②Put the printed 3D model containing tiny primary-color information m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com