A surface-modified magnetic nanoparticle, preparation method, application and regeneration method

A magnetic nanoparticle and surface modification technology, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of strong corrosion of oily wastewater, destroying the ecological balance of water, polluting groundwater sources, etc., and achieves a simple regeneration method. Easy to operate, realize recycling and short adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

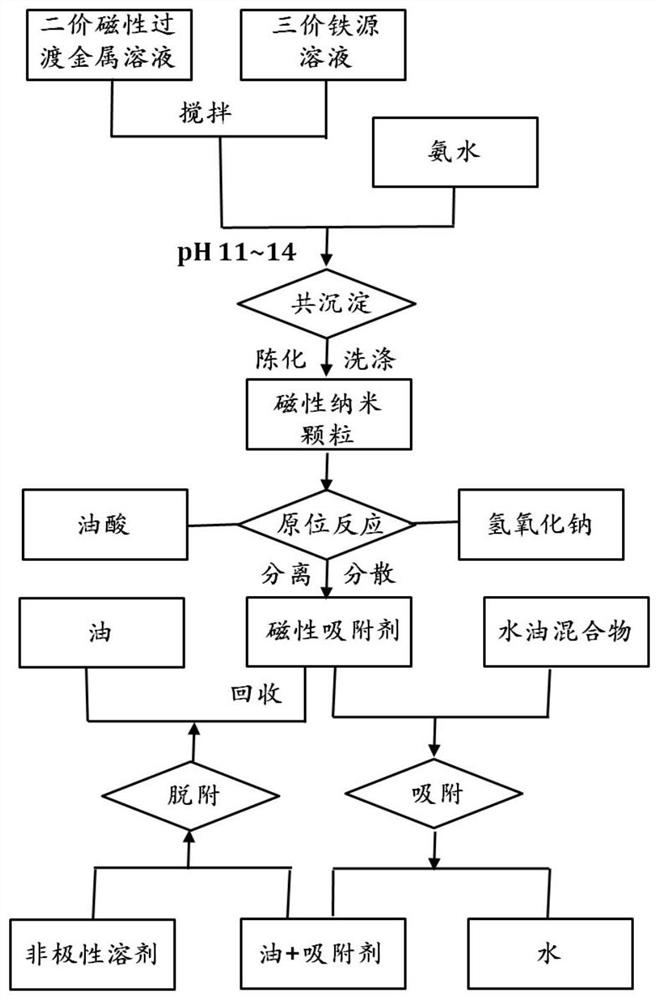

Method used

Image

Examples

Embodiment 1

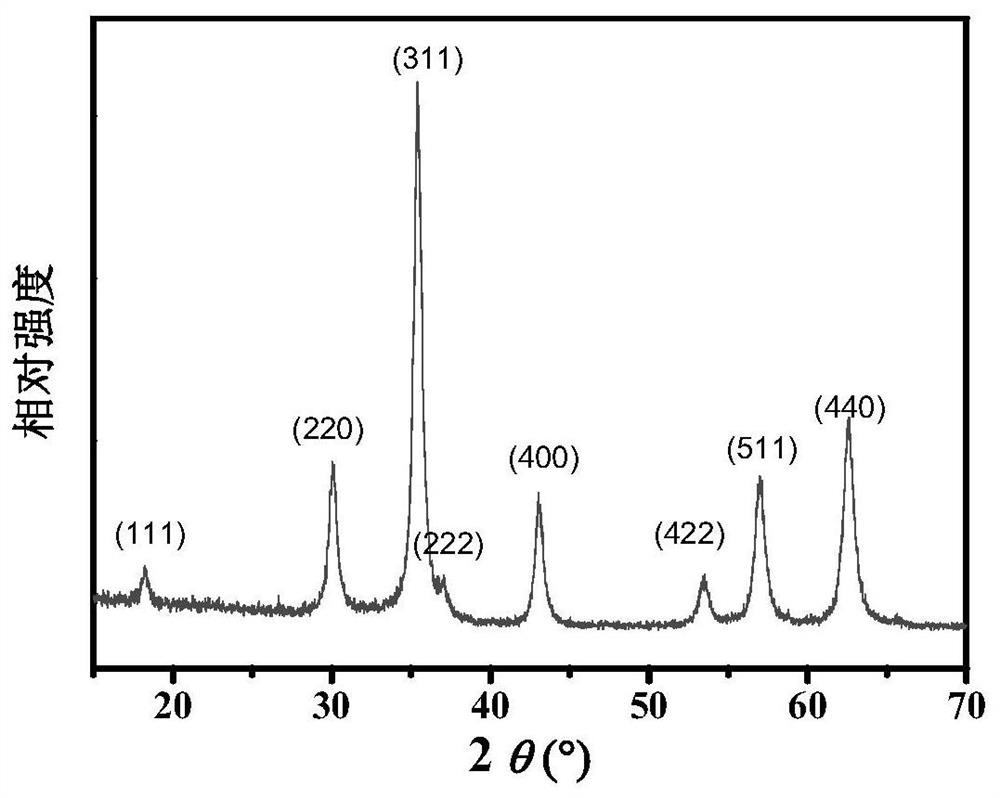

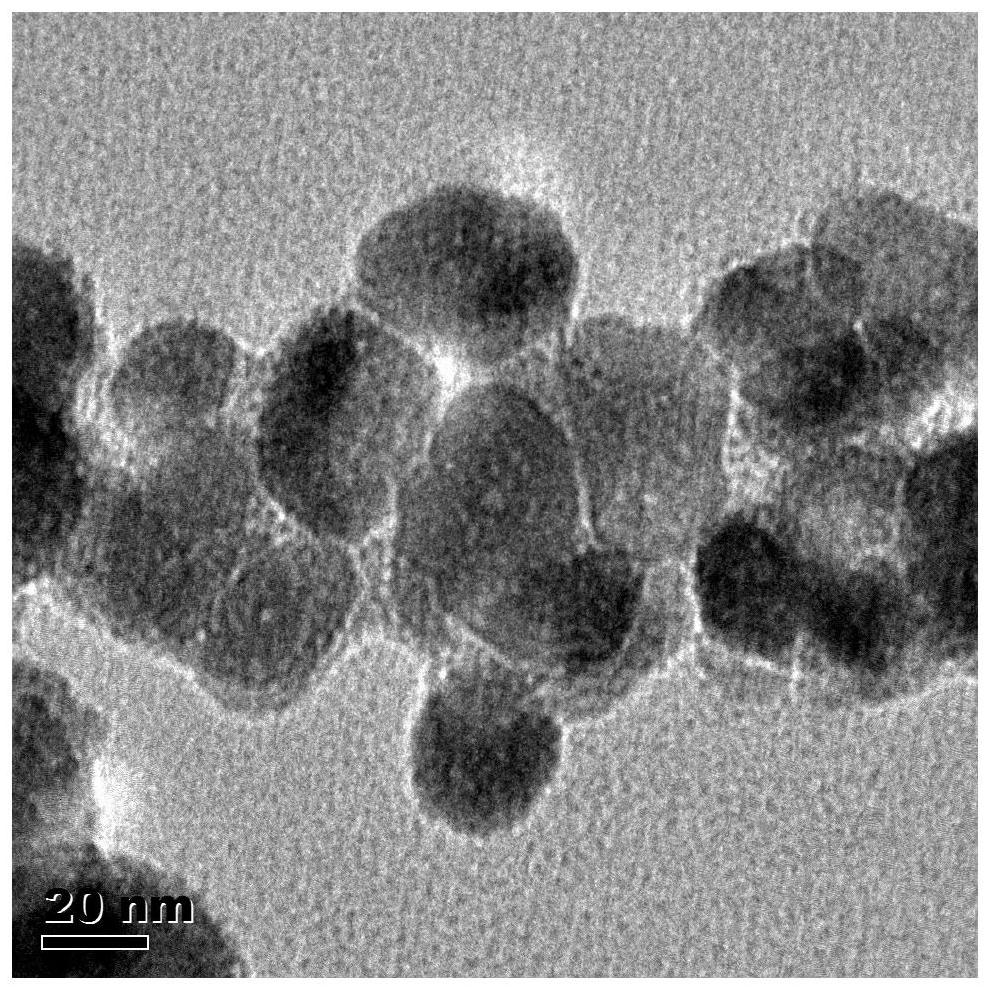

[0035] The preparation of the magnetic nanoparticle of embodiment 1 surface modification

[0036] This embodiment provides a preparation of surface-modified magnetic nanoparticles, including:

[0037] (1) with ferrous chloride and ferric chloride as iron source, the aqueous solution containing 0.02mol ferrous chloride and 0.04mmol ferric chloride is mixed;

[0038] (2) Add a 40% ammonia solution dropwise to the solution under mechanical stirring until the pH value of the solution is stable at 12. The resulting mixture was placed in a water bath, the temperature of the water bath was 70° C., and the time of the water bath was 2 hours. After the water bath, the precipitate was centrifuged and washed several times with pure water to obtain magnetic nanoparticles;

[0039] (3) continue to disperse the precipitate in 100g water, and add 2.82g oleic acid to the water, add the 10g aqueous solution that has dissolved 0.8gNaOH in the stirring process, after standing for a period of t...

Embodiment 2

[0043] The preparation of the cobalt ferrite particle of embodiment 2 surface modification

[0044] This embodiment provides a preparation of surface-modified cobalt ferrite particles, including:

[0045] (1) adopt ferrous chloride and ferric chloride as iron source, will contain the aqueous solution of 0.1mol cobalt chloride and 0.2mmol ferric nitrate to mix;

[0046] (2) Add a 40% ammonia solution dropwise to the solution under mechanical stirring until the pH value of the solution is stable at 12. The resulting mixture was placed in a water bath, the temperature of the water bath was 90° C., and the time of the water bath was 4 hours. After the water bath, the precipitate was centrifuged and washed several times with pure water to obtain magnetic nanoparticles;

[0047] (3) Continue to disperse the precipitate in 200g water, and add 5.64g oleic acid to the water, add 20g aqueous solution in which 2gNaOH has been dissolved in the stirring process, and after standing for a ...

Embodiment 3 4

[0049] Example 3 The oil-water separation effect and recycling of ferric oxide particle adsorbent

[0050] This embodiment provides an oil-water separation effect and a recycling method of the magnetic nanoparticles obtained in Embodiment 1, including:

[0051] Oil-water separation: Disperse 0.2 g of the surface-modified ferroferromagnetic ferric oxide described in Example 1 in 10 g of water, pour the mixed solution into 20 g of oil-water mixture containing 10% crude oil, and mix the two under the action of mechanical stirring uniform. After standing for a period of time, the magnetic nanoparticles are aggregated with a magnet and separated from the solution. It can be seen that the previously brown oil-water mixture became clear after being adsorbed by the magnetic adsorbent.

[0052] Recycling: Disperse the magnetic nanoparticles adsorbed with crude oil in 10g of n-hexane solution, and add 10g of pure water, it can be seen that the crude oil is evenly dispersed in the n-he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com