Synthesis method of bismuth telluride-based semiconductor thermoelectric material

A thermoelectric material, bismuth telluride-based technology, which is applied in the directions of thermoelectric device junction lead-out materials, selenium/tellurium compounds, chemical instruments and methods, etc. efficiency and other issues, to achieve the effect of wide performance adjustment range, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

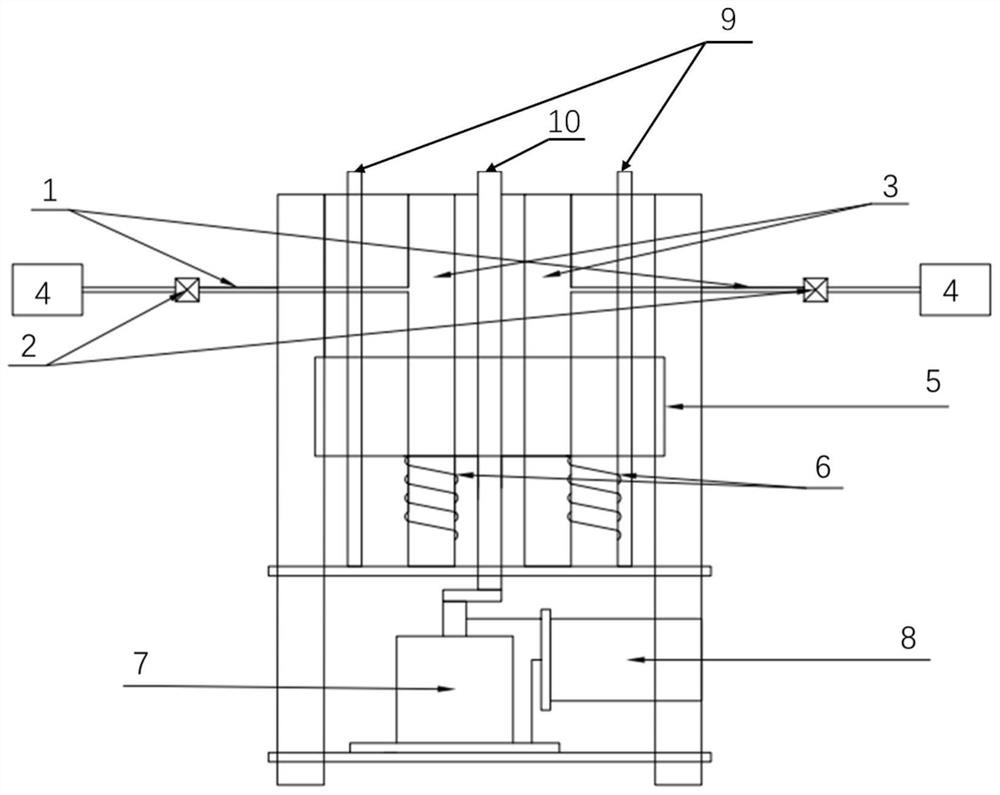

[0033] The synthesis method of bismuth telluride-based thermoelectric material inlaid with N-type nano crystal grains comprises the following steps:

[0034] 1. Place the N bismuth telluride-based thermoelectric material sintered by the fusion method in the vacuum-tight quartz tube in the zone melting-directional solidification vertical zone furnace assisted by inductive coupling, and move the columnar heating ring to the bottom of the quartz tube, and set the heating The temperature is 973K;

[0035] 2. After the temperature reaches 973K, stabilize for 30 minutes, start the induction coupling auxiliary heating system, and set the frequency to 600KHz;

[0036] 3. Set the heating body lifting speed to 0.2mm / min, start the heating body lifting device, and slowly lift the heating body;

[0037] 4. When the upper edge of the zone melting resistance heating body reaches the upper edge of the top material in the quartz tube, high-purity argon gas is introduced at a flow rate of 2 S...

Embodiment 2

[0041] The synthesis method of bismuth telluride-based thermoelectric material inlaid with P-type nano crystal grains comprises the following steps:

[0042] 1. Place the P bismuth telluride-based thermoelectric material sintered by the fusion mixing method in a vacuum-tight quartz tube in a zone melting-directional solidification vertical zone furnace assisted by inductive coupling, move the columnar heating ring to the bottom of the quartz tube, and set the heating The temperature is 893K,;

[0043] 2. After the temperature reaches 893K, stabilize for 30 minutes, start the induction coupling auxiliary heating system, and set the frequency to 800KHz;

[0044] 3. Set the heating body lifting speed to 0.5mm / min, start the heating body lifting device, and slowly lift the heating body;

[0045] 4. When the upper edge of the zone melting resistance heating body reaches the upper edge of the top material in the quartz tube, high-purity argon gas is introduced at a flow rate of 5 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com