An intelligent 4~20ma two-wire photoelectric level transmitter

A two-wire, transmitter technology, used in instruments, liquid level indicators, machines/engines, etc., can solve the problems of difficult instrument maintenance, strict requirements for the production process of Gray code belts, and difficulty in selecting safety barriers. Convenient two-way data transmission and instrument maintenance, strong data error correction processing ability, and the effect of reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention relates to the technical field of level measuring instruments, in particular to an intelligent 4-20mA two-wire photoelectric level transmitter circuit.

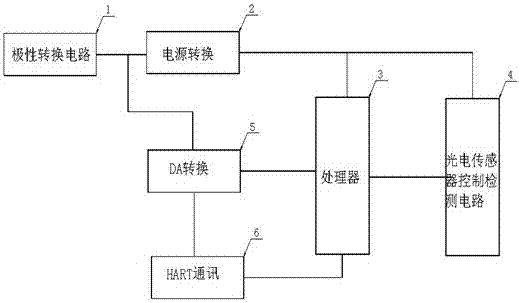

[0023] see figure 1 , the details of an intelligent 4-20mA two-wire photoelectric level transmitter involved in the present invention are:

[0024] Including a processor 3, and a power conversion circuit 2 connected to the processor 3, a photoelectric sensor control detection unit 4, a DA converter 5 and a HART communication unit 6; wherein, the processor 3 controls the acquisition of the photoelectric sensor control detection unit 4 to obtain liquid Level signal, the liquid level signal is converted into a 4-20mA standard signal through the DA converter 5, and the 4-20mA carrier wave through the HART communication unit 6 complies with the Bell202 international standard protocol to realize two-way digital communication between the transmitter and the control room .

[0025] The present invention may als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com