A Miniature Flapping Rotor Aircraft with Differential Flapping of Two Wings

An aircraft, flapping rotor technology, applied in the direction of unmanned aircraft, aircraft, micro-aircraft, etc., can solve the huge difference in lift contribution and transient energy consumption, large wing lift and transient energy consumption, system lift fluctuation It can reduce the maximum power consumption of the wing, improve the energy utilization efficiency, and reduce the difficulty of design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

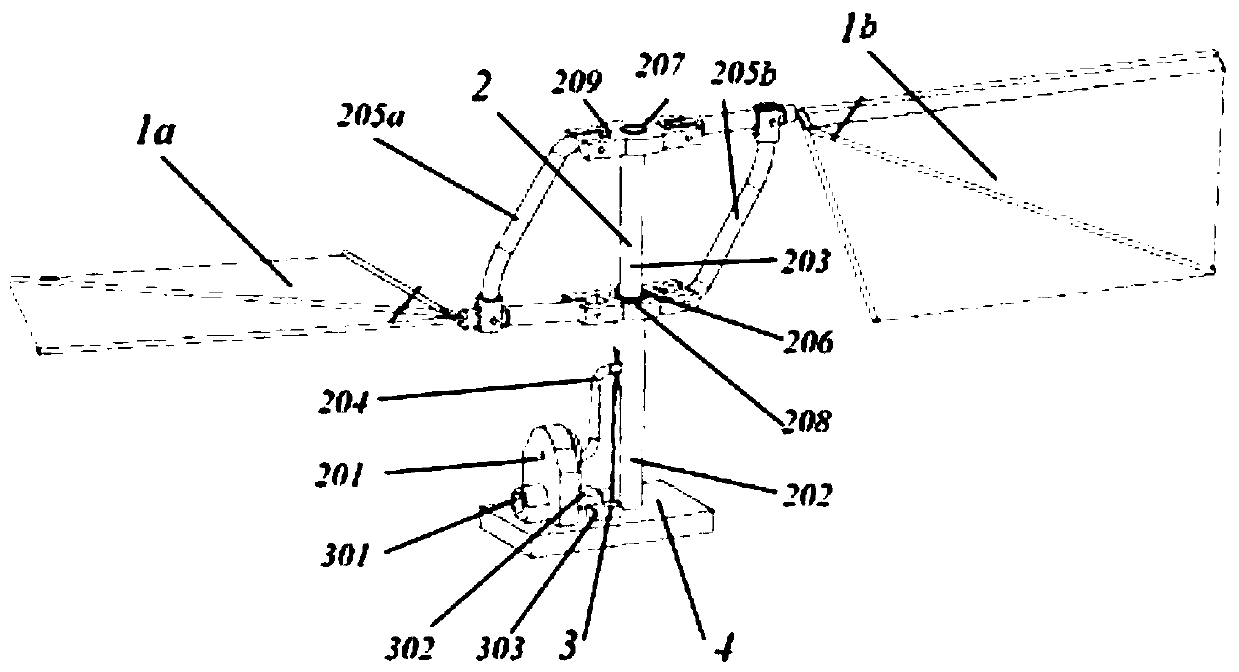

[0026] The present invention is a miniature flapping rotor aircraft with differential flapping of two wings. The left and right wings are flapped differentially, and the flapping difference is about 180 degrees, that is, when one wing flaps downwards, the other flaps upwards. When the average lift is kept constant during flapping of the wings at the same frequency, the lift is more uniform throughout the flapping cycle, and the maximum output power of the motor only needs to be slightly greater than the maximum power of a single wing when flapping down, which effectively reduces a During the flapping process, the maximum power consumption of the wing and the transient lift fluctuation can significantly improve the energy utilization efficiency of the aircraft.

[0027] Described miniature flapping rotor aircraft, such as figure 1 As shown, it include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com