Intelligent rope end knotting machine

A technology of knotting machine and rope end, applied in the direction of sewing unit, cloth feeding mechanism, sewing machine components, etc., can solve the problems of tweezers damage, needle collision, poor control of tweezers, etc., to achieve strong practicability and save processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

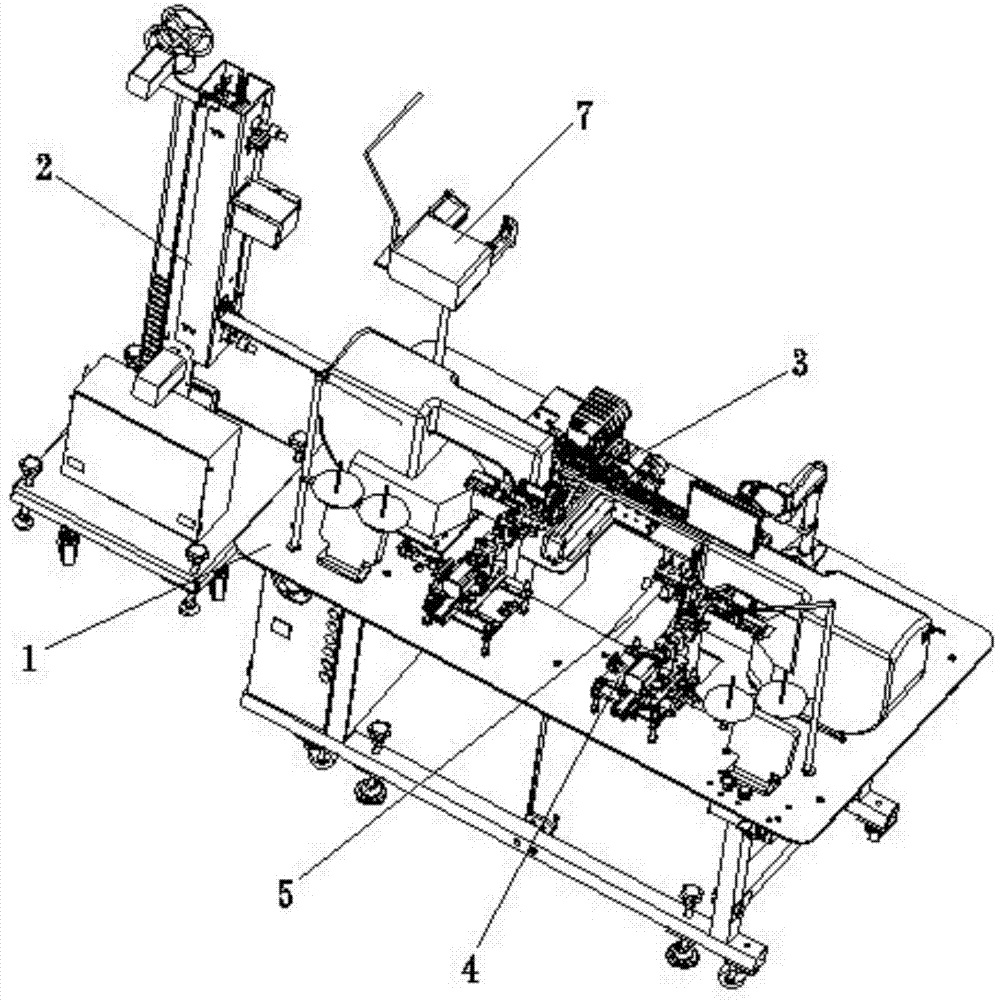

[0032] The present invention will be illustrated below in conjunction with the accompanying drawings (the front, back, left, right, up and down in the following description are all in accordance with the appended figure 1 direction is standard).

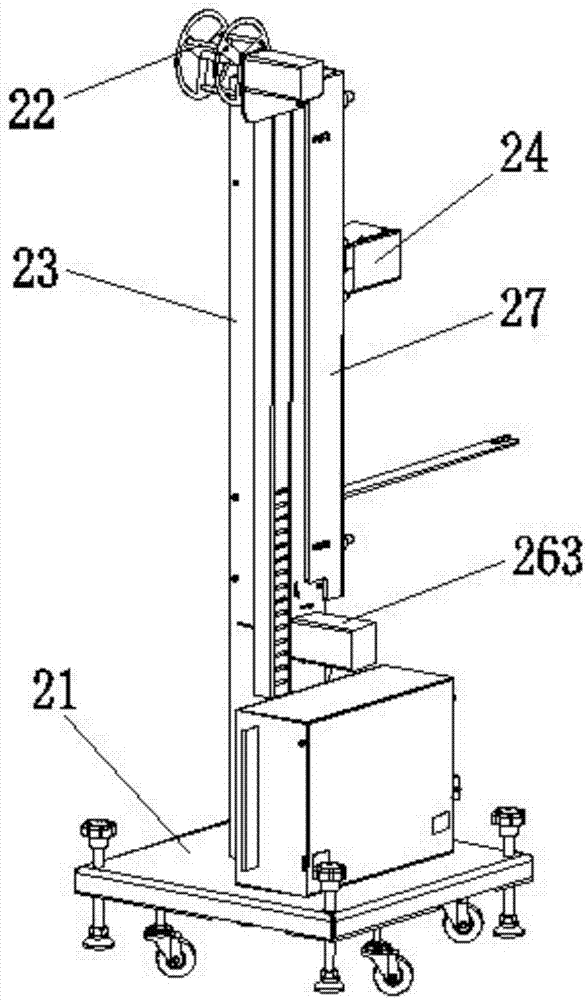

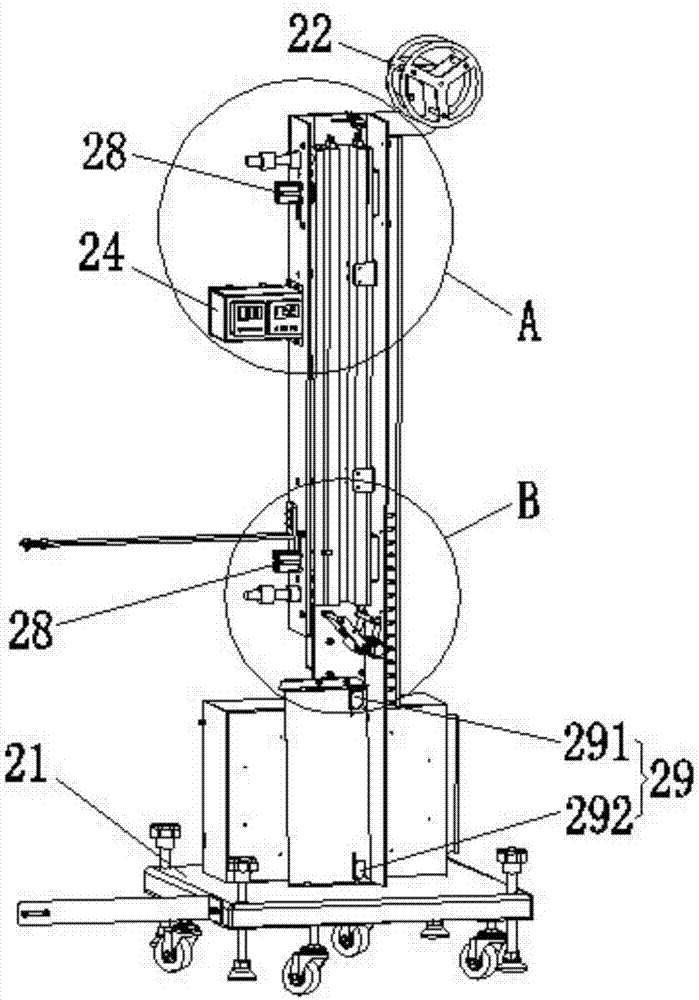

[0033] The intelligent rope knotting machine of the present invention, as attached Figure 1-15As shown, it includes a frame 1, a rope ironing mechanism 2 arranged on one side of the frame, a rope feeding mechanism 3 and a rope winding mechanism 4 installed on the frame; the rope feeding mechanism 3 includes a length measuring device 7, Cutting device 8, pushing device 9; Said belt ironing device 2 comprises a base 21, and a winder 22 and an ironing box 23 arranged on the base 21 sequentially from top to bottom; The ironing box 23 includes a heating 24, ironing board 25, pull cord 26 and shell 27; Said ironing board 25 comprises fixed plate 251 and movable heating plate 252 that are fixedly connected on the inside of shell 27; Said ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com