Looseness defect image generation method based on texture synthesis

A technology of texture synthesis and image generation, applied in 2D image generation, image analysis, texture/color, etc., can solve the problems affecting the detection accuracy of the algorithm, and achieve the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

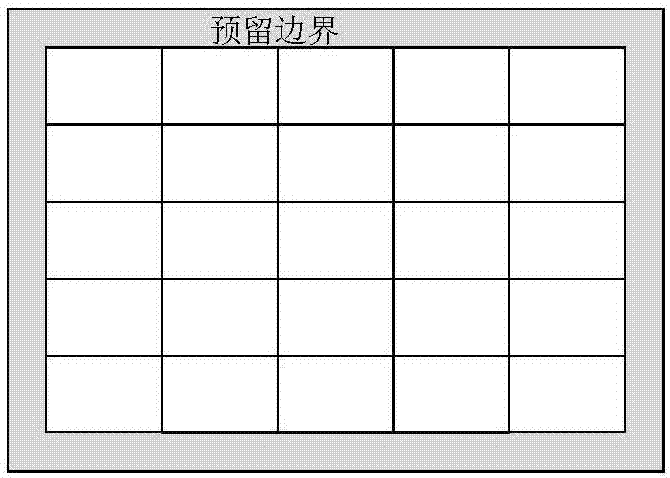

[0041] Figure 5 It is the method of the present invention to obtain a new workpiece map with generation defects according to the actual workpiece map with loose texture defects, comprising the following steps:

[0042] (1) Normalize the X-ray image of the actual workpiece with loose texture defects, and cut out suitable defect samples;

[0043] (2) remove the background image in the sample;

[0044] (3) In a new workpiece image, according to the required area size, select a rectangular area as the defect generation area at any desired position of the workpiece;

[0045] (4) Utilize the new texture image generation process shown in Figure (1) to generate a new defect texture image with the same size as the selected defect generation area;

[0046] (5) Superimposing the generated defect texture image on the position of the workpiece image, that is, obtaining a new workpiece image with generated defects. The superposition method is to add the gray value of each pixel in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com