Paper cutting device

A cutting and paper technology, applied in metal processing and other directions, can solve problems such as affecting the cutting effect and forming wrinkles, and achieve the effect of ensuring the cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

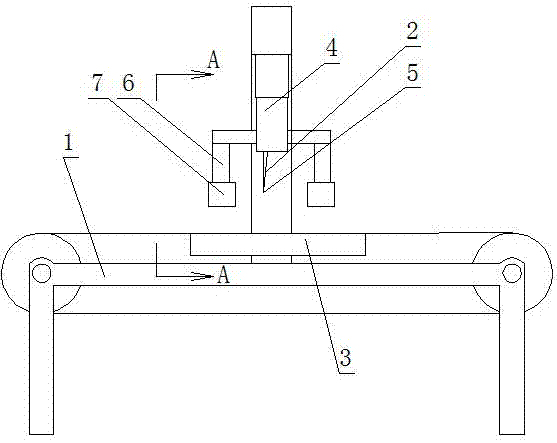

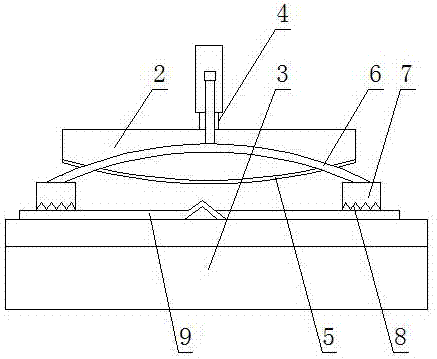

[0016] Such as figure 1 , 2 Shown, a kind of paper cutting device comprises cutting device body, and described cutting device body has conveying frame 1, has cutting knife 2 on the conveying frame, below cutting knife is cutting platform 3, also has Cylinder 4 is connected with cutting knife, and there is blade 5 below cutting knife, and cutting knife runs downwards, can finish cutting to paper; It is characterized in that: described cutting knife side installs a stretch pressing plate 6, and described stretching The two ends of pressing plate are downward arc structures, and rubber blocks 7 are installed below the two ends of the stretching pressing plate, and the following two ends of the stretching pressing plate exceed the blade portion.

[0017] Like this, during the use of the present invention, the cutting knife moves downwards, and the stretching press plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com