A blasting parameter optimization method to ensure the safety of ground buildings

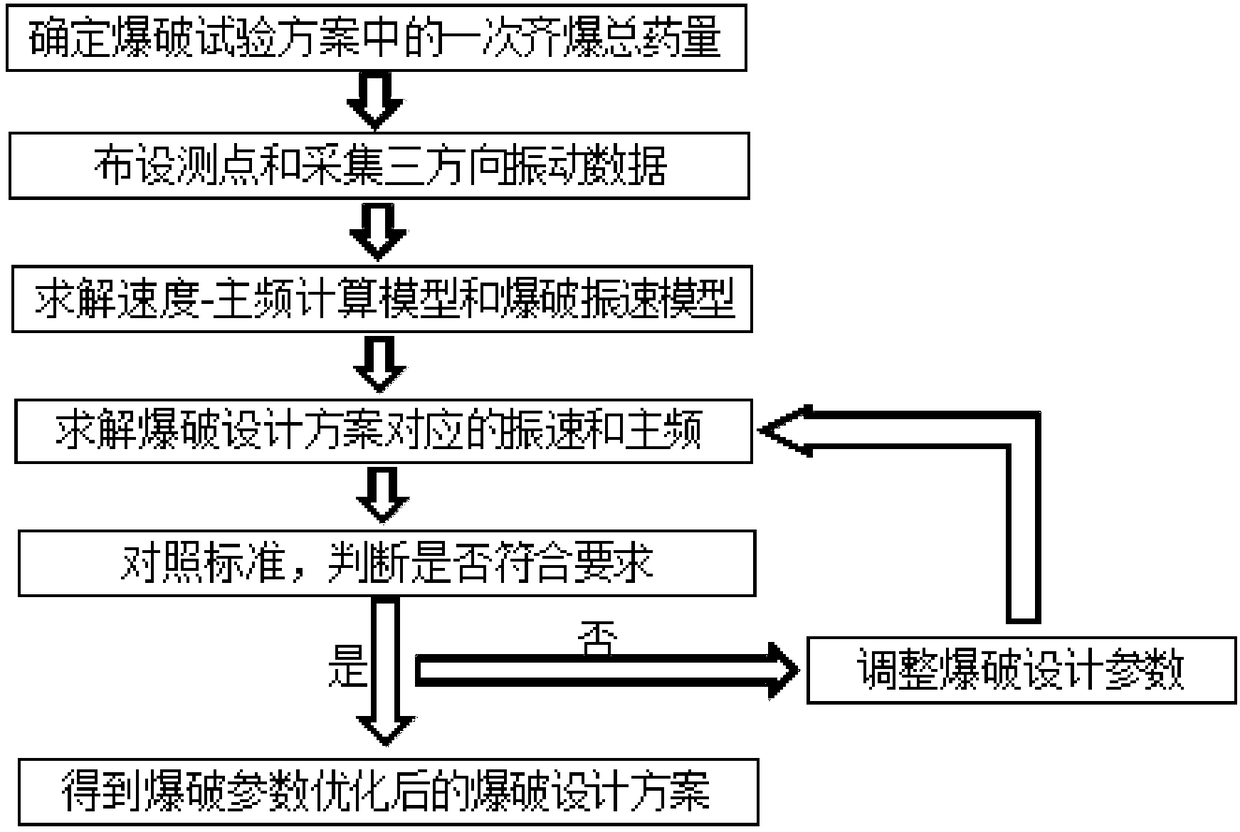

An optimization method and building technology, which are applied in the field of blasting parameter optimization and blasting design parameter optimization to ensure the safety of ground buildings, can solve problems such as low driving speed and reduced construction efficiency, and achieve strong applicability, simple operation, and prevention of civil accidents. Effects of economic disputes and delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

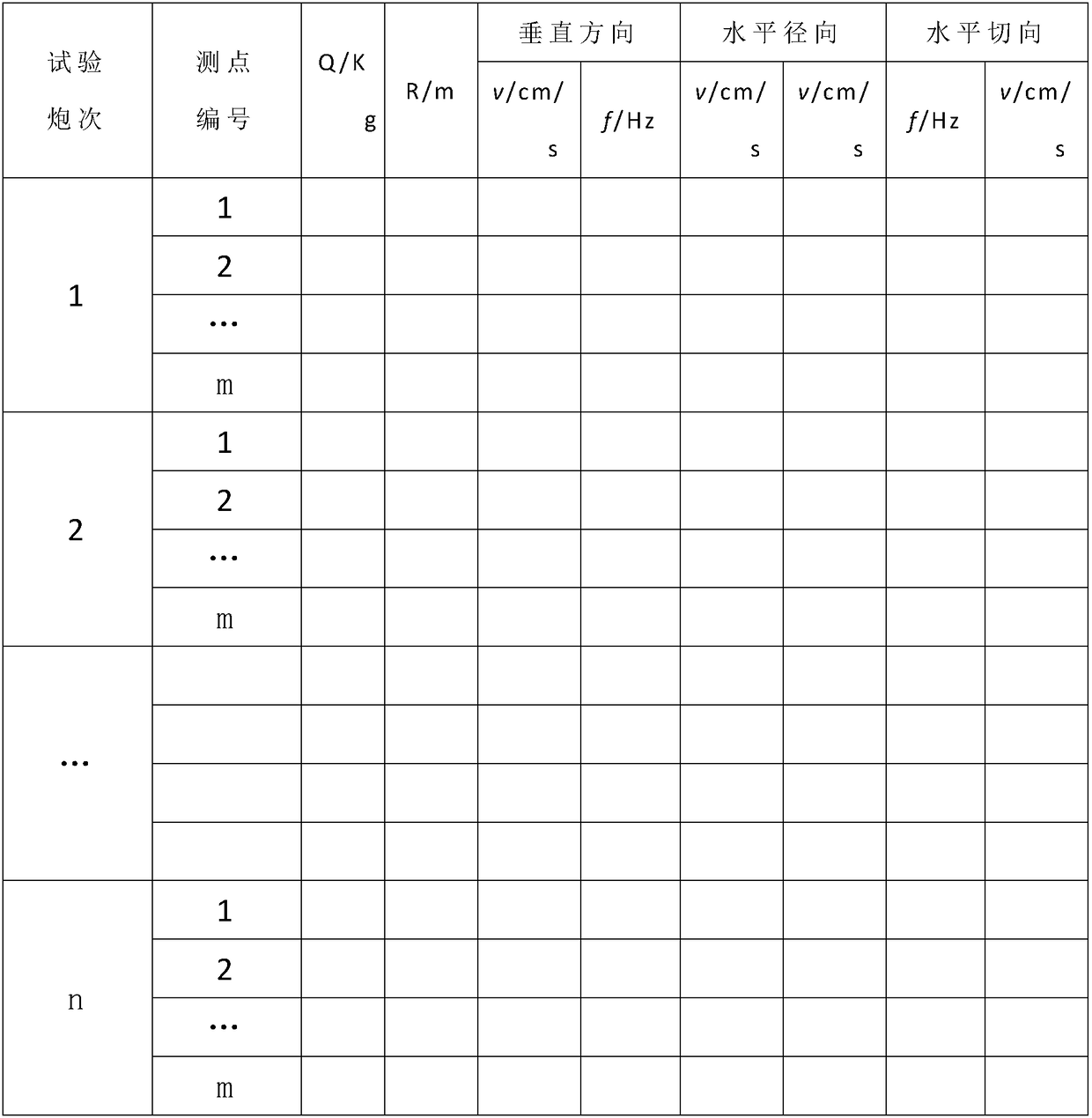

[0056] Step 1: Select a foundation excavation and blasting project site to carry out the blasting test. The bedrock in the blasting area is severely weathered granite and gneiss. The distance between the test blasting source and the nearest residential building is 55m. It is a medium-hard rock, the highest charge Q in one burst max =3.6*10^(-5)*r^3=3.6*10^(-5)*55^3=5.99Kg. The hole depth is 2m, the hole diameter is 40mm, the single hole charge is 0.9kg, the plugging length is 1.3m, the holes are arranged in a single row, and the hole distance is 1.2m. The number of test shots n is set to 3, the test shots are numbered 1, 2, and 3 in turn, and the number of holes in each shot is 3, 4, and 6 respectively. The doses were 2.7Kg, 3.6Kg and 5.4Kg respectively, none of which exceeded 5.99Kg.

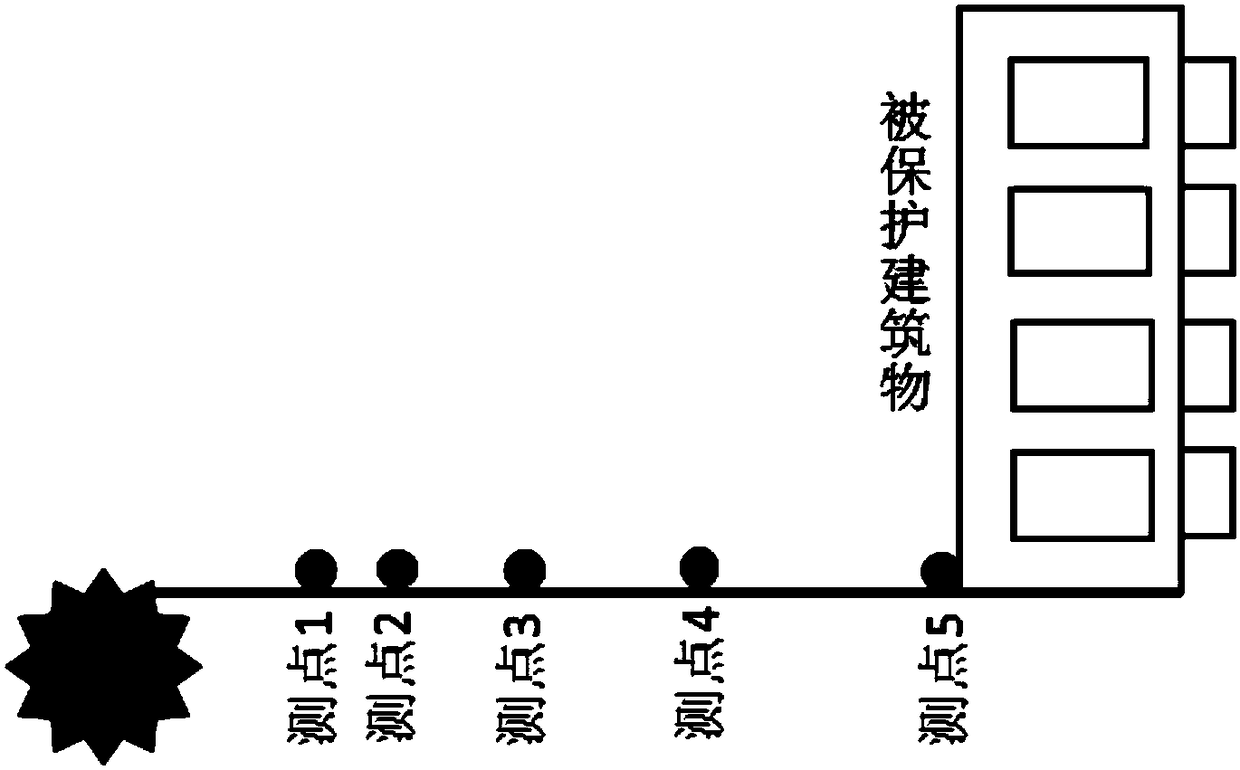

[0057]Step 2: First determine the location of the explosion source corresponding to test shot 1, and the distance from the nearest residential building is 55m. Along the direction of the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com