Analysis method for forecasting periodic lattice-material yield surface

An analysis method and periodic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of improving modeling efficiency, shortening data processing time, and achieving greater accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] Such as Figure 6 As shown, the present invention predicts the analysis method of periodic lattice material yield surface, comprises the following steps:

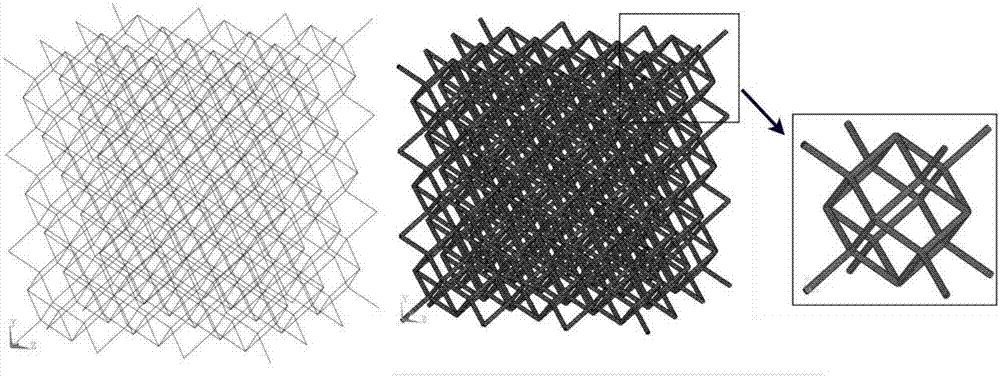

[0039] (1) According to the structural characteristics and size characteristics of the actual lattice material, select an appropriate mesomechanics model to describe, in order to figure 1 The lattice material shown is taken as an example, which can be regarded as a lattice material composed of three-dimensional truss structures, and the trusses can be described by beams in the mechanical model.

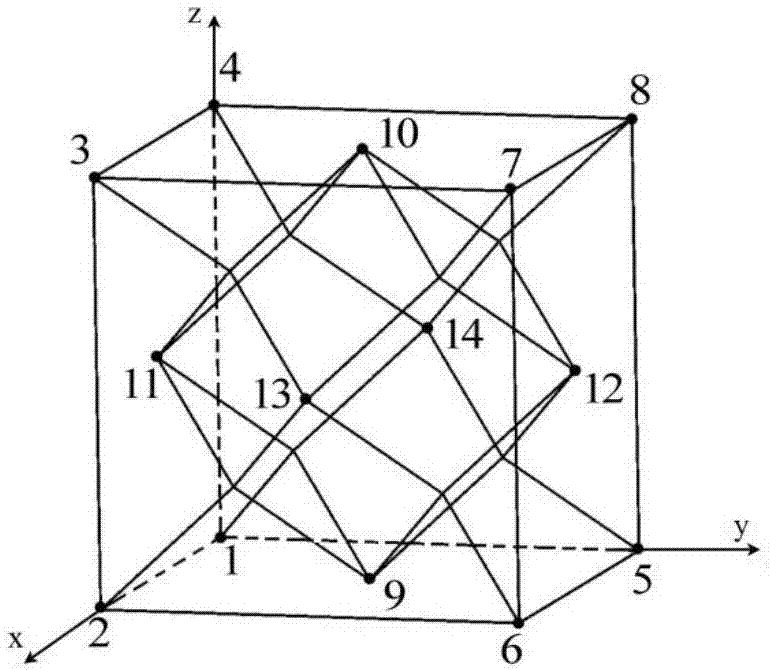

[0040] (2) According to the periodic arrangement of the mesomechanics model, select figure 2 Shown is a representative voxel (RVE) that can reproduce the actual structure through a simple array arrangement.

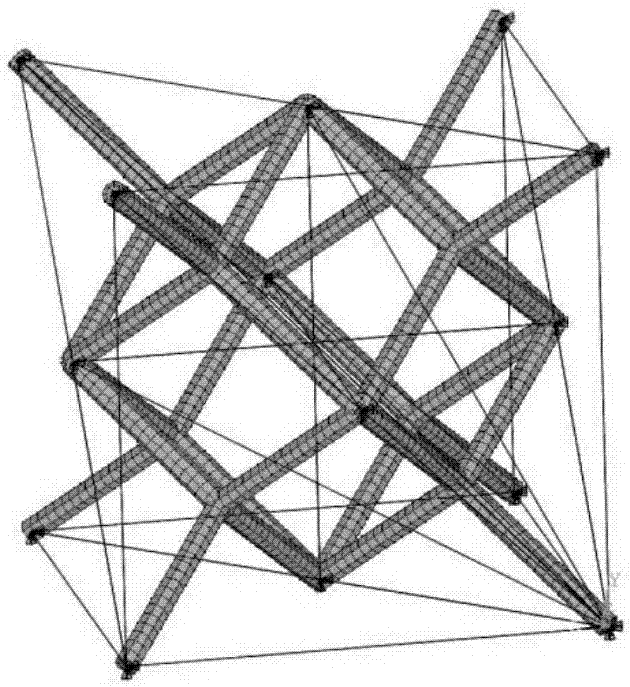

[0041] (3) According to the corresponding RVE, considering the coupling effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com