Foldable bus crane span structure

A bridge and busbar technology is applied in the field of foldable busbar bridges, which can solve problems such as unfavorable and rapid construction, and achieve the effects of reducing transportation costs, reducing occupied space, and facilitating rapid installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A foldable bus bridge of the present invention will be described in detail below with reference to the accompanying drawings.

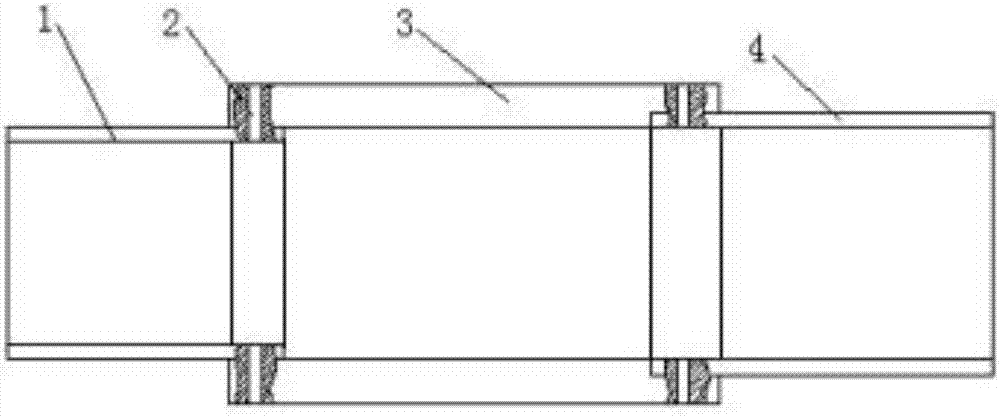

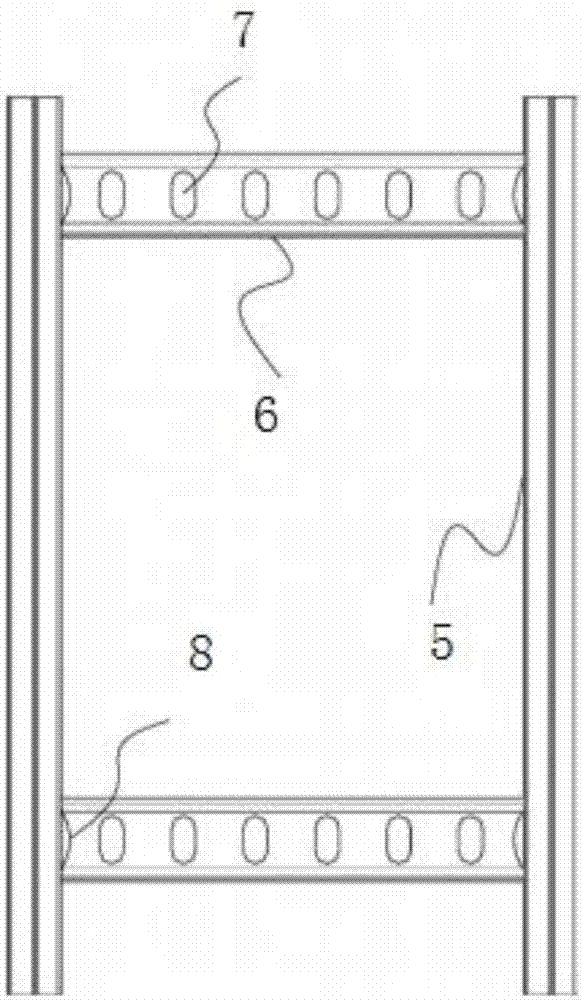

[0014] Such as figure 1 and figure 2 As shown, a foldable busbar bridge includes a bridge body 3, and the two sides of the bridge body are respectively connected with a first bridge body 1 and a second bridge body 4 through hinge points 2; the bridge body 3 includes two parallel distributed A crossbeam 6 is welded between the longitudinal beam 5 and the longitudinal beam 5; the two ends of the crossbeam 6 are provided with arc-shaped gaps 8 for welding, and a number of through holes 7 are evenly distributed on the crossbeam 6, and the two ends of the longitudinal beam 5 are respectively provided with There are installation holes; the hinge point 2 is a screw that passes through the first bridge body and the bridge body and a nut that cooperates with the screw; the cross-section of the cross beam 6 is a hollow rectangle, and the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com