Rice cooker

A technology of electric rice cooker and cooking body, which is applied to the utensils with integral electric heating device, the structure of cooking utensils, cooking utensils, etc., which can solve the problems of large time difference, overcooked rice, and the effect of cooking rice, and achieve gelatinization Fully uniform, rapid and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In conjunction with the accompanying drawings, the present invention will be further described below using a fusible alloy with a melting point of 70 degrees Celsius as a phase change material and a heating device consisting of 4 independent units as a specific example.

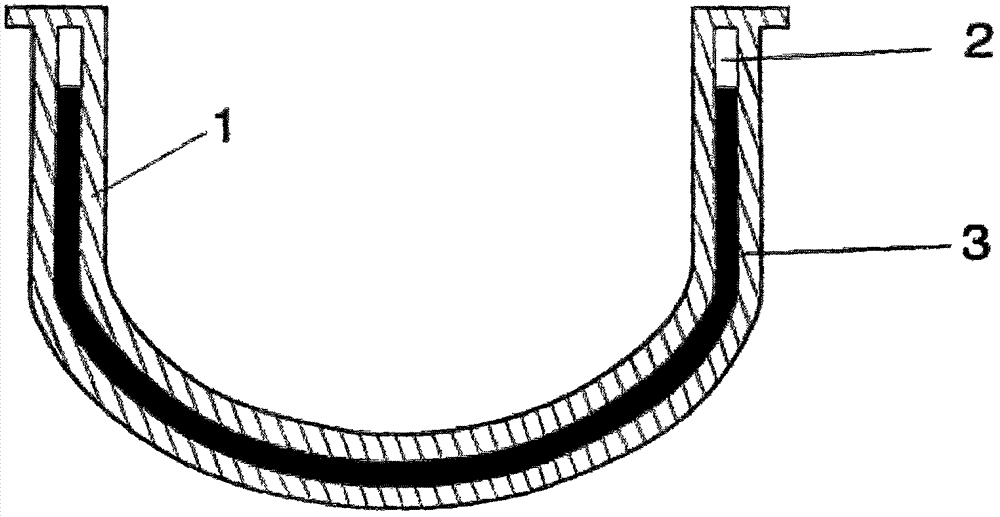

[0013] Reference attached figure 1 , 2 , the present invention includes an inner pot 1 and a pot body 4 of an electric rice cooker.

[0014] The wall of the inner pot 1 has a double-layer structure with a cavity 2 inside and is sealed. The cavity 2 is filled with a phase-change material 3, and the phase-change material 3 adopts a fusible alloy with a melting point of 70 degrees Celsius in this embodiment.

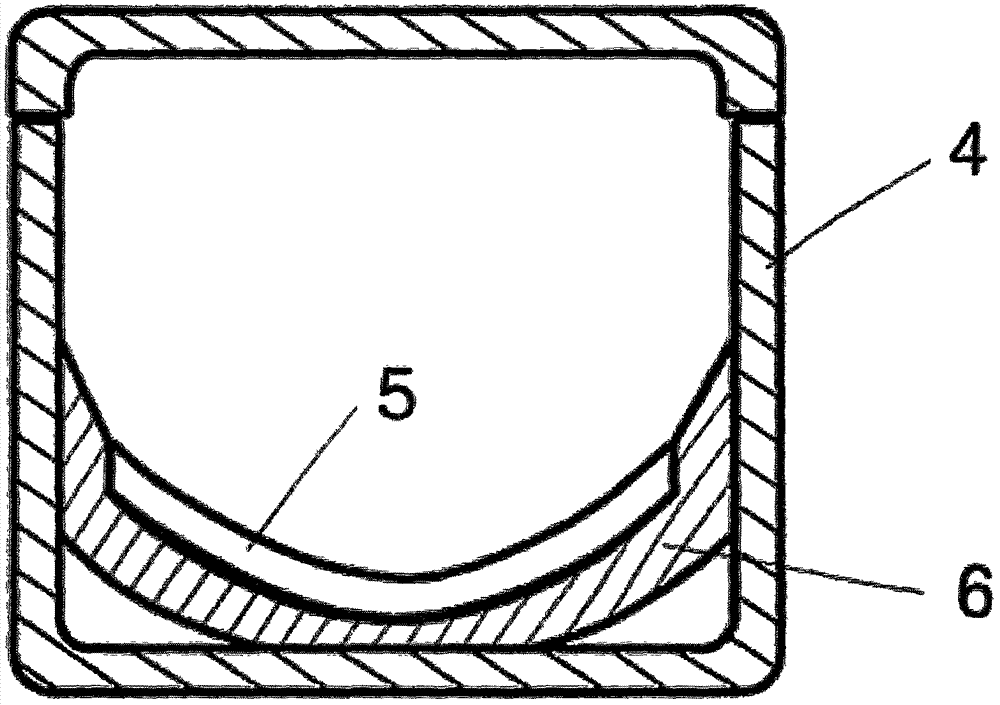

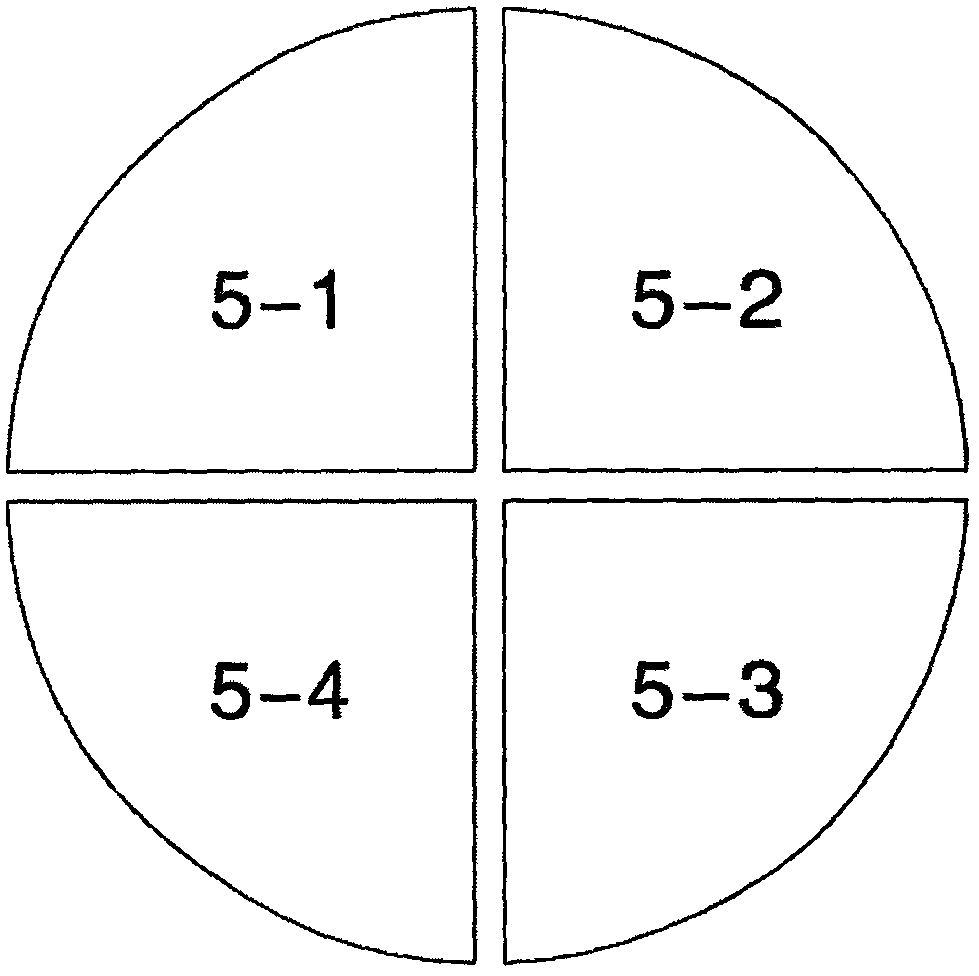

[0015] A heating device 5 and an electromagnetic drive device 6 are arranged in the pot body 4, and the heating device 5 is composed of 4 independent heating units 5-1, 5-2, 5-3, and 5-4.

[0016] When the inner pot 1 is put into the pot body 4, the heating device 5 is placed under the inner pot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com