Heat exchanging water tank of water fountain

A technology for exchanging hot water tanks and drinking fountains, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of long cooling time, easy to be polluted by the external environment, and cooling speed affected by heat dissipation performance, so as to reduce energy and improve energy saving. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

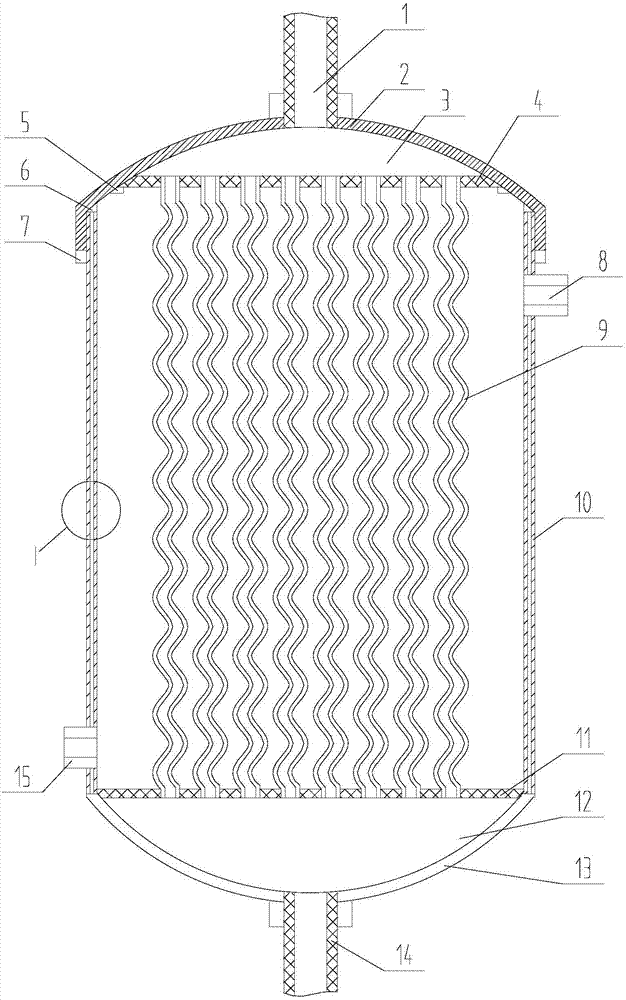

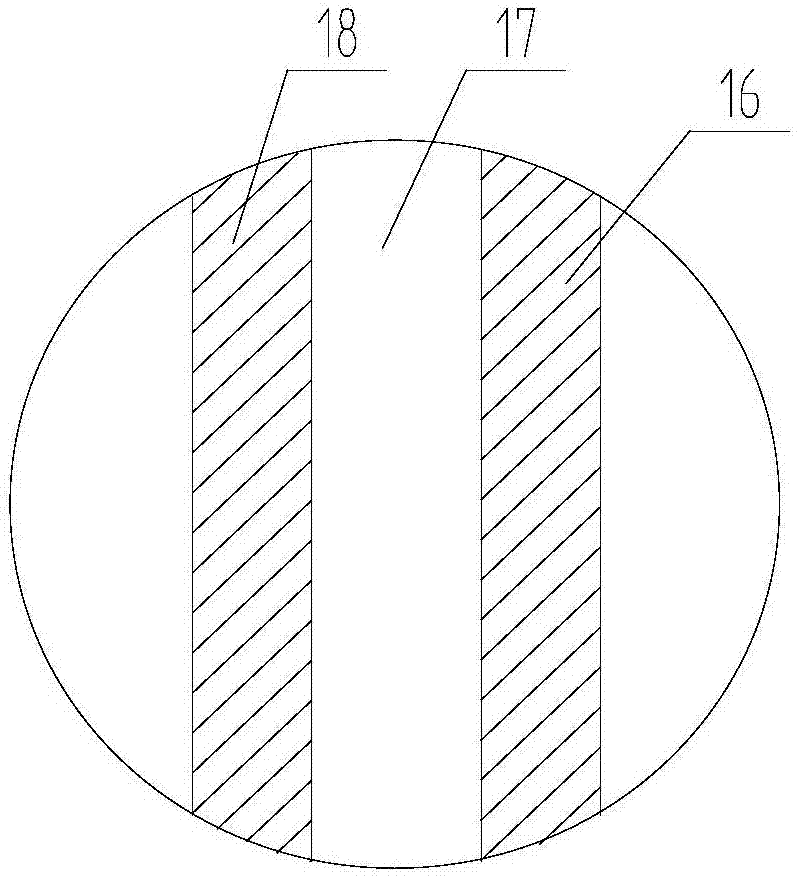

[0023] Embodiment 1: A water exchange tank for a water dispenser, including a box body 10, the box body 10 is cylindrical, its top is an arc-shaped cover 2, and its bottom is an arc-shaped base 13 integrated with it. The interior includes the hot water dispersion chamber 3 formed by the upper fixed plate 4 and the arc-shaped cover body 2, the hot water collection chamber 12 composed of the lower fixed plate 11 and the arc-shaped base 3, the hot water collection chamber 12 and the hot water dispersion chamber 3 A spiral heat exchange tube 9 is installed between them. The two ends of the heat exchange tube 9 are straight pipes, and the middle part is a spiral pipe. Connect with threaded connection. The upper and lower ends of the box body 10 are respectively connected with a hot water inlet pipe 1 and a hot water outlet pipe 14, and the hot water inlet pipe 1 and the hot water outlet pipe 14 respectively penetrate the hot water dispersion chamber 3 and the hot water collection c...

Embodiment 2

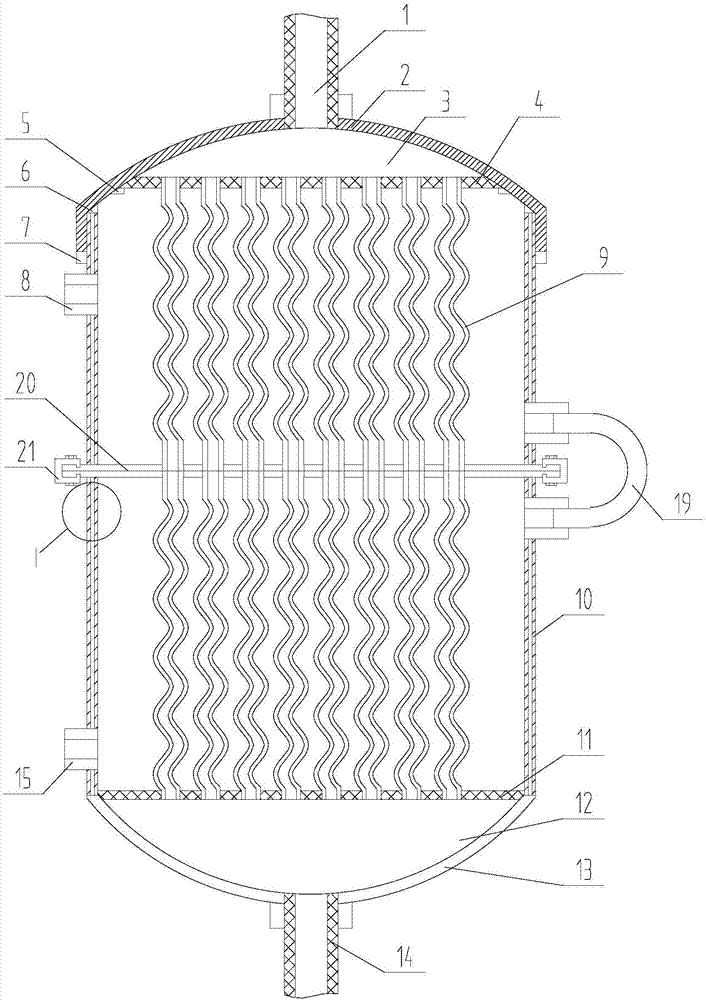

[0024] Embodiment 2: A water exchange tank for a water dispenser, wherein the box body 10 is divided into upper and lower parts connected by a middle partition 20 and a buckle 21, and the middle partition 20 is provided with an upper fixing plate 4 and a lower The through holes at the same position of the fixing plate 11 and the heat exchange tubes 9 are installed at the through holes. The structures and connections of the remaining parts are the same as those described in any of the foregoing embodiments.

[0025] In view of the foregoing embodiments, when the application is in use, its working process and principle are as follows:

[0026] The purpose of the heat exchange tank of the water dispenser of the present invention is to add a heat exchange box to the water dispenser so that the boiled drinking water can exchange heat with the original cold water in the water dispenser through pipes, so as to reduce the boiling time. The temperature of plain boiled water obtains th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com