Stacked barrel type self-cleaning efficient electrostatic oil fume purification unit

An oil fume purification and self-cleaning technology, applied in the field of electrostatic fume purification devices and oil fume purifiers, can solve the problems of high technical requirements, easy to be broken down and burned, occupying a large volume, etc., to reduce the size of the whole machine and improve the electronic activation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

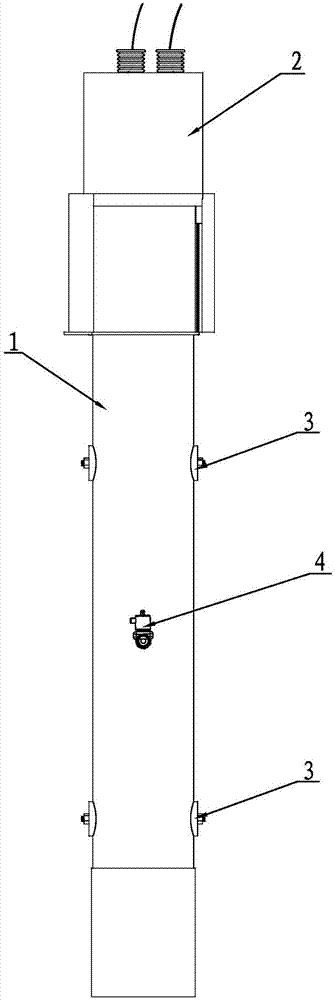

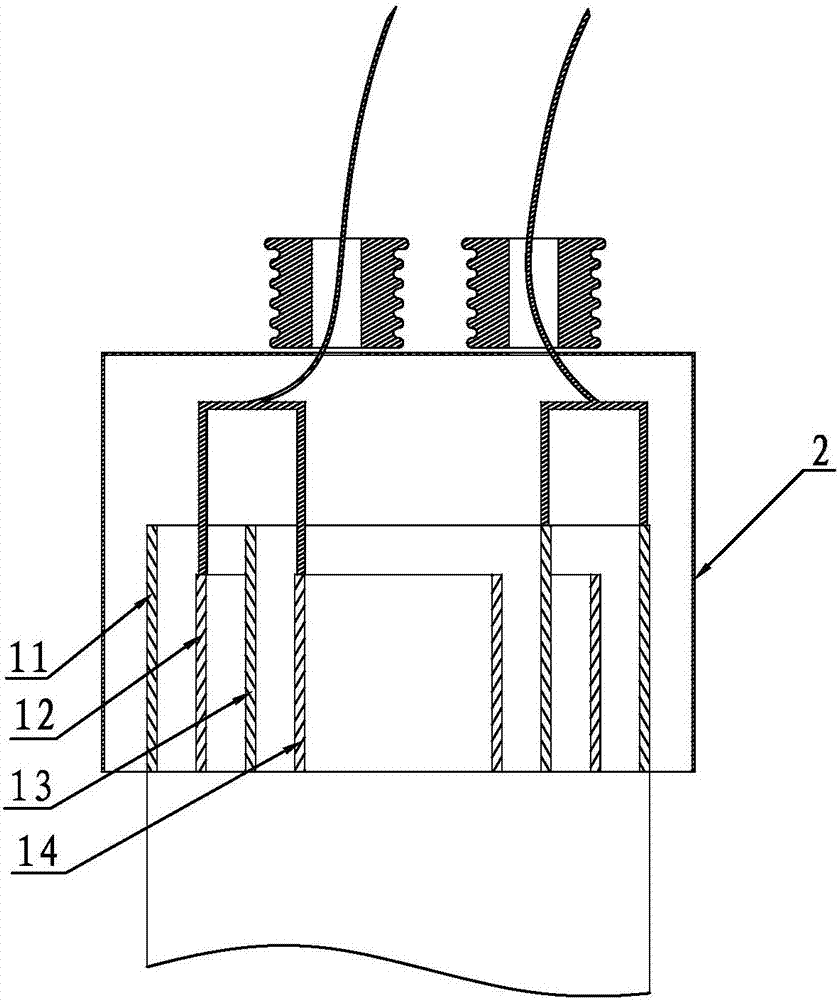

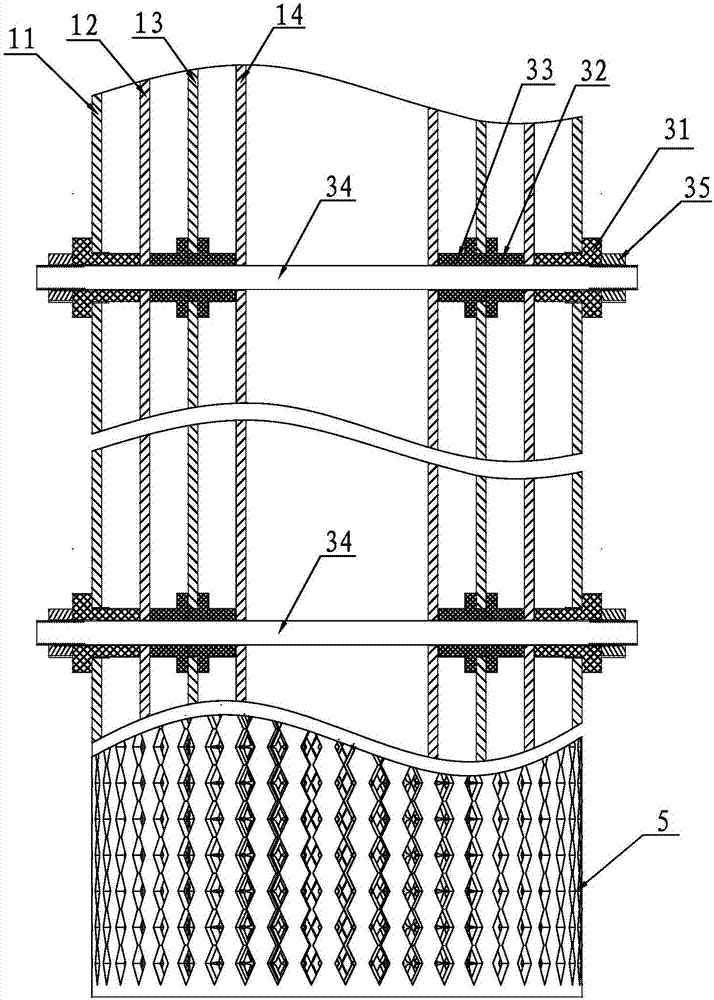

[0030] Embodiment 1: A stacked cylinder type self-cleaning high-efficiency electrostatic oil fume purification unit, such as Figure 1 to Figure 10 As shown, it includes a metal stacked sleeve body 1, an electrode distributor 2, an insulating distance connection assembly 3 and a cleaning part 4. The metal stacked sleeve body 1 has a metal outer tube 11 with a diameter of 100 mm and a diameter of 80 mm. The first metal sleeve 12, the second metal sleeve 13 with a diameter of 60 mm and the coaxial metal inner tube 14 with a diameter of 40 mm are assembled together, the outer metal tube 11, the first metal sleeve 12, the second metal sleeve 13 and the The metal inner tube 14 is coaxially distributed, and the tube wall of each metal bobbin tube is evenly provided with a prismatic discharge hole, which is the activation discharge structure 5 of the corona area. In this example, the width of the corona activation area is 20 cm , 20 cm upwards from the suction end, in the metal stack...

Embodiment 2

[0031]Embodiment 2: The difference from Embodiment 1 is that in the metal stacked cylinder body 1, the difference of the inter-pipe insulation distance connection assembly 3 is: in the metal outer tube 11, the metal sleeve 12, and the metal sleeve The two 13 and the metal inner tube 14 are provided with coaxially distributed through holes with the same diameter, and a radial insulating spacer 36 is arranged between two adjacent metal bobbins, and the insulating connecting screw 34 passes through all the metal bobbins The same-diameter through hole and the inner hole of the radial insulating spacer 36, both ends are radially fixed by shoulder nuts 37, such as Figure 5 shown.

Embodiment 3

[0032] Embodiment 3: as Figure 6 As shown, the insulated fixed-distance connection assembly 3 is provided with equidistant coaxial insulating races 6 at both ends of all metal bobbins, and the equidistant coaxial insulating races 6 are fixed on the metal outer tube by fasteners 7 1 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com