Preparation of biochar-modified ferrocobalt bimetallic composite catalyst and application of biochar-modified ferrocobalt bimetallic composite catalyst in catalytic degradation of tetracycline

A composite catalyst, bimetallic technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the limitation of antibiotic wastewater application and hinder the surface active site of catalyst , two-dimensional catalysts are easy to agglomerate and accumulate problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

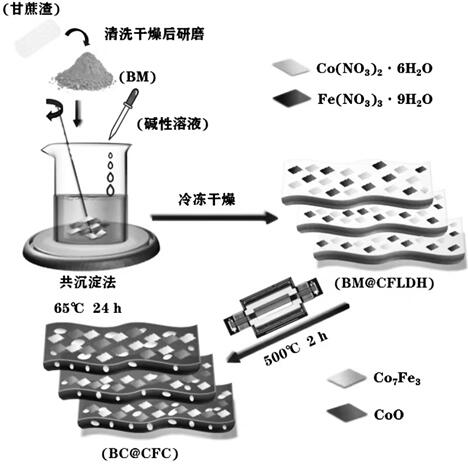

[0094] (1) The biomass bagasse (BM) was repeatedly washed with deionized water and ethanol. Dry in an oven at 80°C for 24 hours, and grind for later use.

[0095] (2) BM, 2 mmol Co(NO 3 ) 2 ·6H 2 O and 1 mmol Fe(NO 3 ) 3 9H 2 O was added to 100 mL deionized water and stirred for 30 min to make it evenly dispersed. Control the mass ratio of BM to the total mass of cobalt and iron to be 1:2. Subsequently, through 7mmol NaOH and 3mmol Na 2 CO 3 Adjust the pH of the mixed solution to 10-10.5. After sonicating for 30 min, stir at 65 °C for 24 h. The resulting precipitate was repeatedly washed with ultrapure water and ethanol. Then, the precipitate was frozen with liquid nitrogen and placed in a freeze dryer for 24 h to form BM 1 @CF 2 LDH.

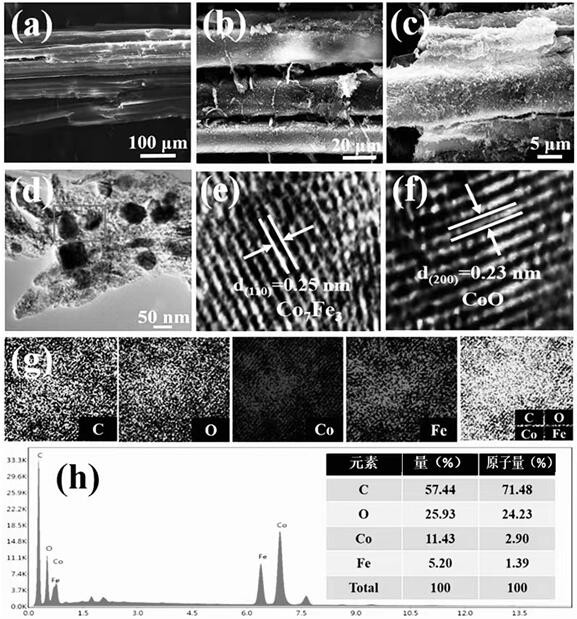

[0096] (3) will BM 1 @CF 2LDH was placed in a tube furnace under the protection of nitrogen, and annealed at 500 ° C for 2 hours to obtain BC 1 @CF 2 c. BC 1 @CF 2 The C / PMS system effectively degraded 92.49% of TC (20 mg / L...

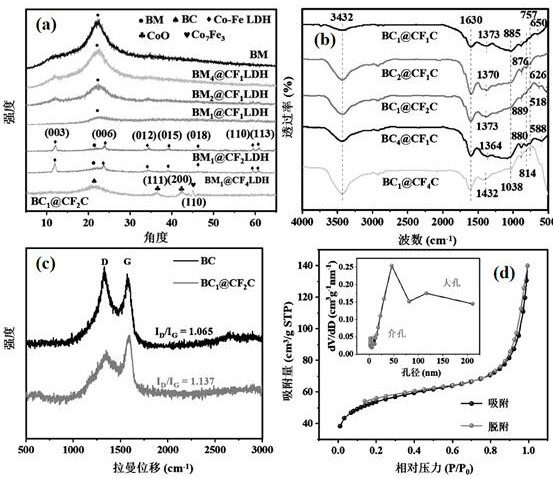

Embodiment 2

[0098] In step (2), the mass ratio of BM to the total mass of cobalt and iron is controlled to be 1:1, and BM is formed in step (2) 1 @CF 1 LDH, finally get BC in step (3) 1 @CF 1 C, all the other steps are the same as in Example 1. BC 1 @CF 1 The C / PMS system can effectively degrade 90.04 % of TC (20 mg / L) within 30 min.

Embodiment 3

[0100] In step (2), the mass ratio of BM to the total mass of cobalt and iron is controlled to be 2:1, and BM is formed in step (2) 2 @CF 1 LDH, finally get BC in step (3) 2 @CF 1 C, all the other steps are the same as in Example 1. BC 2 @CF 1 The C / PMS system can effectively degrade 87.12% of TC (20 mg / L) within 30 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com