Expanding sleeve with automatic mechanical jaw device

A jaw, automatic technology, applied in the field of expanding and shrinking sleeves, can solve the problems of long strip head length, reduce labor productivity, increase the area of spare parts warehouse, etc., to facilitate manufacturing and processing, improve labor productivity, and save movement effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

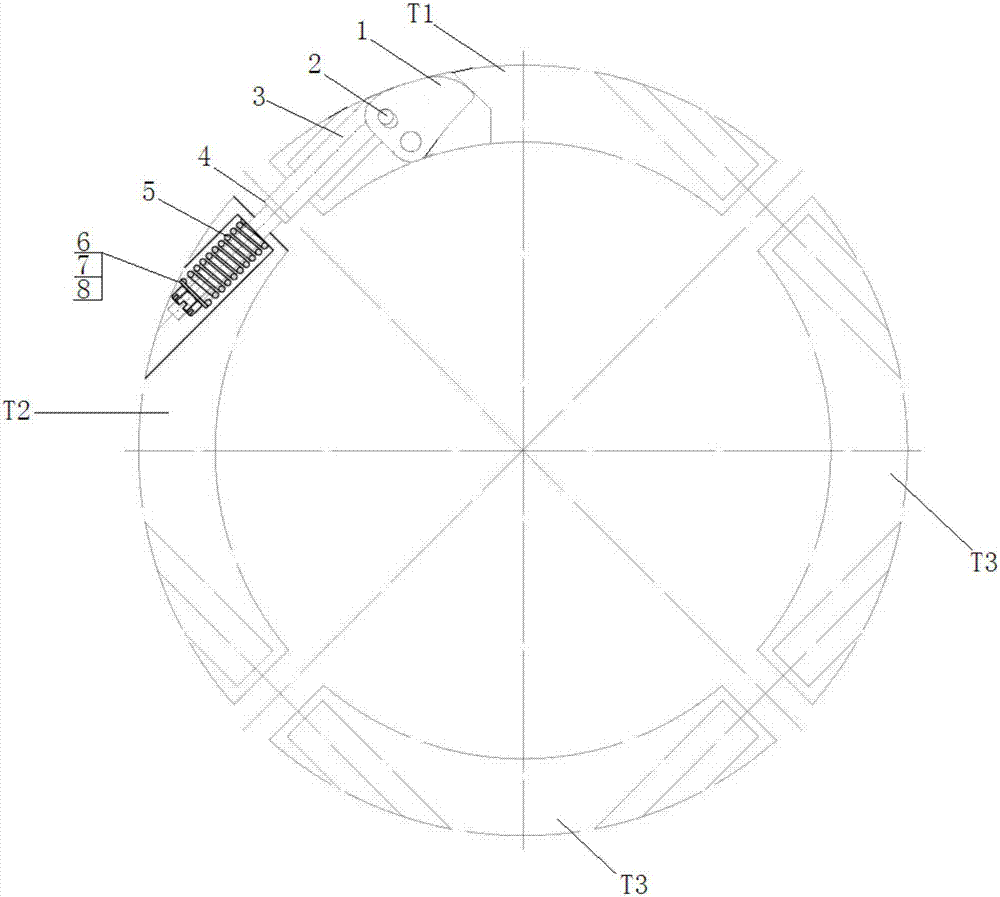

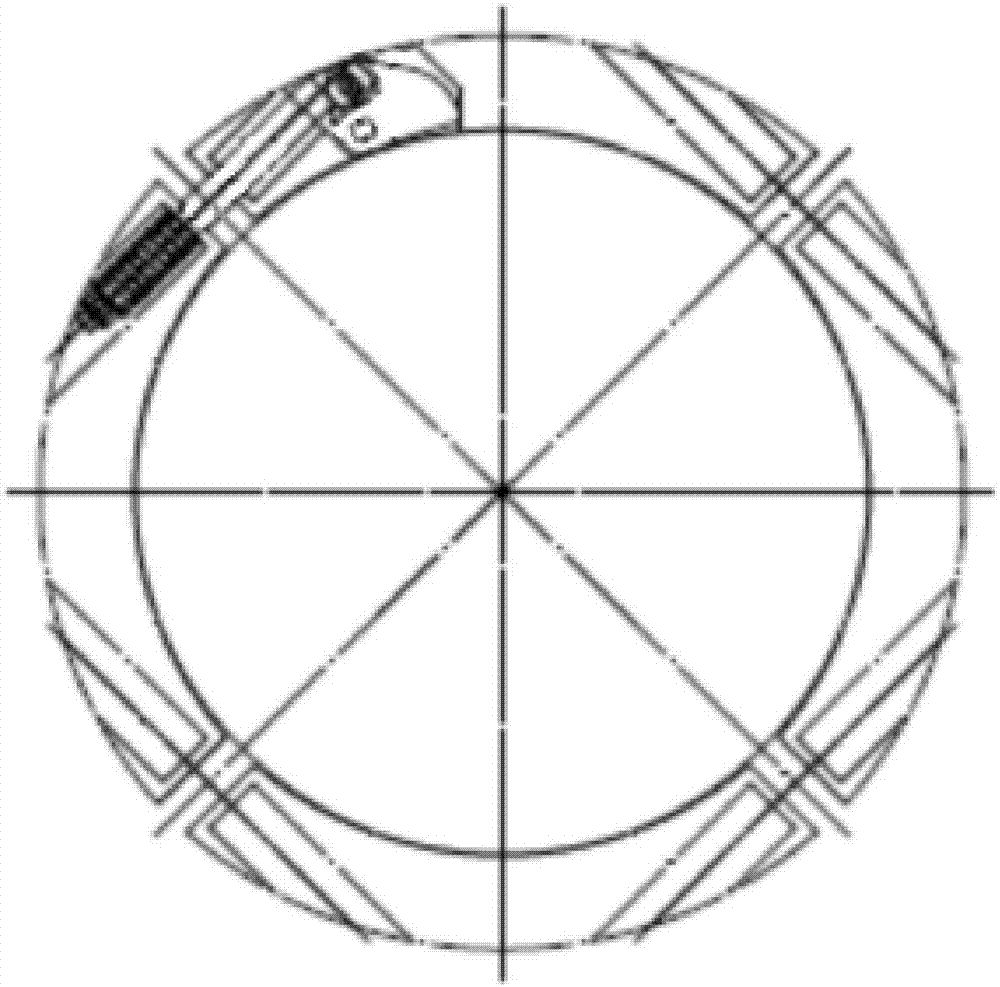

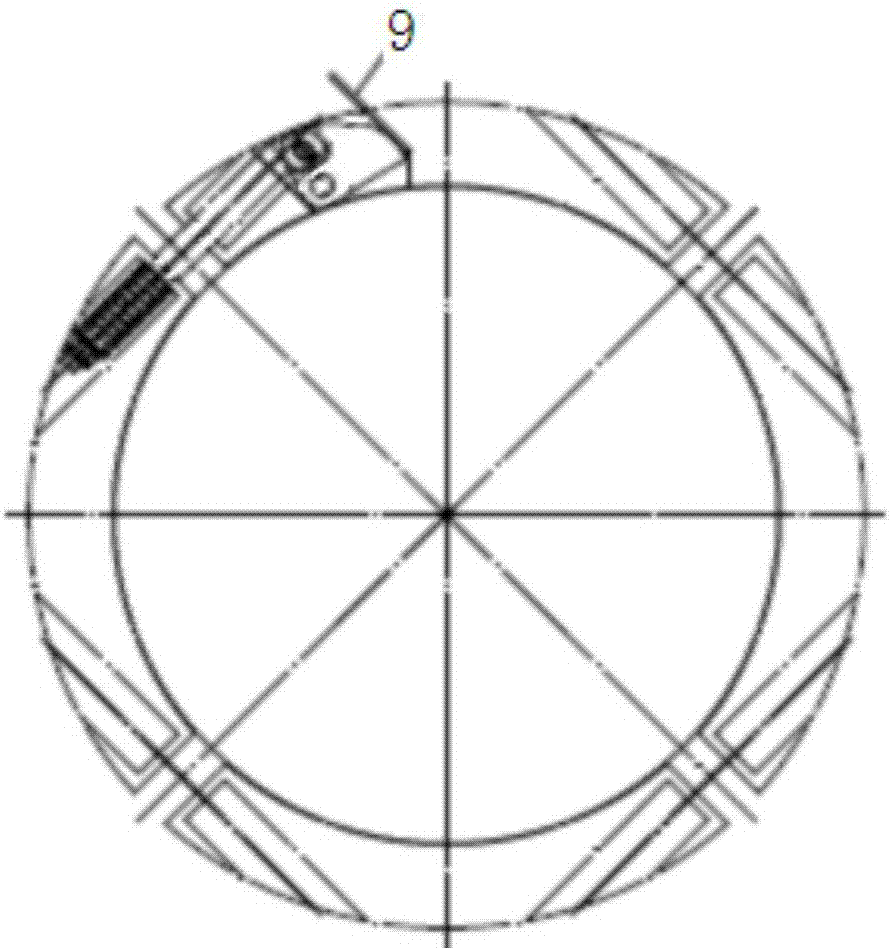

[0030] Such as Figure 1 to Figure 5 As shown, an expansion and contraction sleeve with a mechanical automatic jaw device is used to cooperate with the reel, including a cam 1, a connecting rod 3, a spring 5 and several sector blocks surrounding a circular cylinder. The outer surface of the fan-shaped block T1 is provided with a jaw, and the side is provided with a side hole K1 communicating with the jaw. The side of the fan-shaped block T2 is provided with a side hole K2 facing the side hole K1. The cam 1 is hinged on the fan-shaped block T1 and Located in the jaws, the cam 1 can be tightly attached to and adjust the opening degree of the jaws when it swings. The two ends of the connecting rod 3 extend into the side hole K1 and the side hole K2 respectively, and the connecting rod 3 and the cam 1 pass through the pin shaft 2 and the pin. The hole fits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com