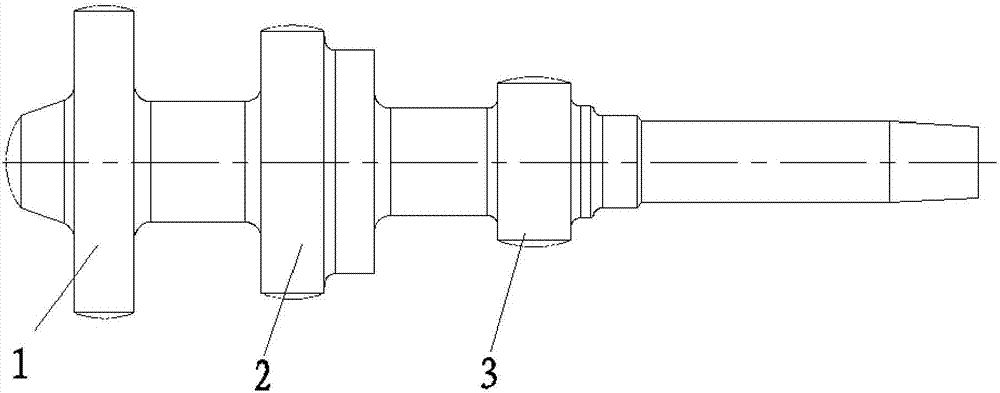

Forming method for flashless forging of intermediate shaft forged pieces

An intermediate shaft and flash-free technology, which is applied in the direction of manufacturing tools, engine components, forging/pressing/hammer devices, etc., can solve the problems of high mold cost, many equipment personnel, long process, etc., and achieve high material utilization rate and process The effect of short process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

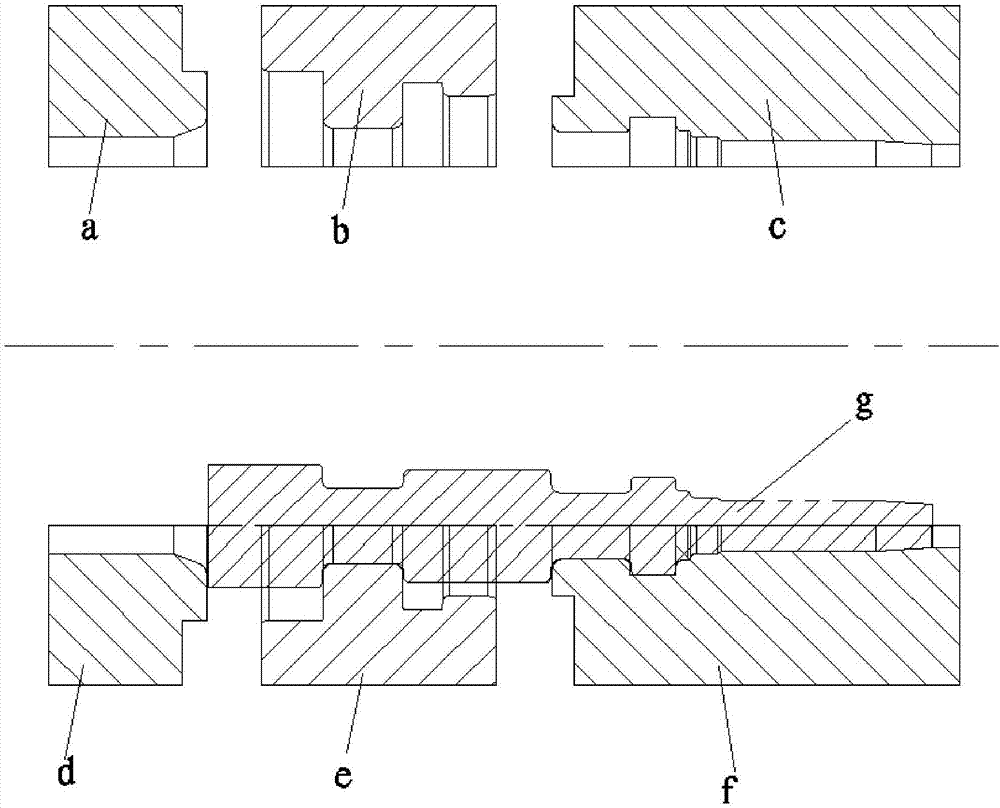

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

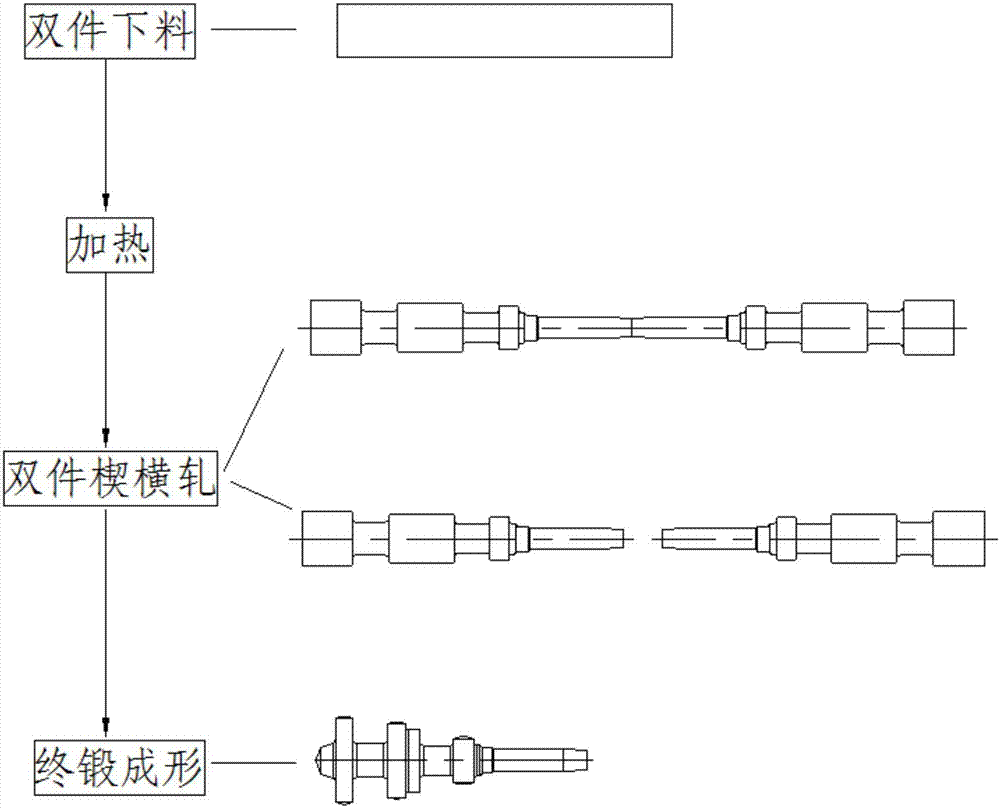

[0024] To proceed as figure 1 Flashless forging of the intermediate shaft type parts shown, using such as figure 2 The shown process flow chart specifically comprises the following steps:

[0025] The first step: double-piece blanking.

[0026] The material is selected according to the diameter of the bar material being smaller than the maximum diameter of the final formed forging. For example, the maximum diameter of the final formed forging is 93mm, and a bar with a diameter of 60mm can be used, and the diameter of the bar is 60% of the maximum diameter of the final formed forging. ~75%; the weight of the bar is twice the weight of the final formed forging for double blanking.

[0027] The second step: heating, put the bar that has been prepared according to the specifications into the heating furnace, and heat it to the initial forging temperature befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com