Novel flexible finger

A flexible finger and finger technology, applied in the field of flexible fingers, can solve the problems such as the inability of flexible fingers to adapt to fast grasping, the limitation of service life and compressive strength, and the limitation of flexible fingers arrangement, so as to achieve accurate and reliable grasping action and sealing. Good sex, little shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

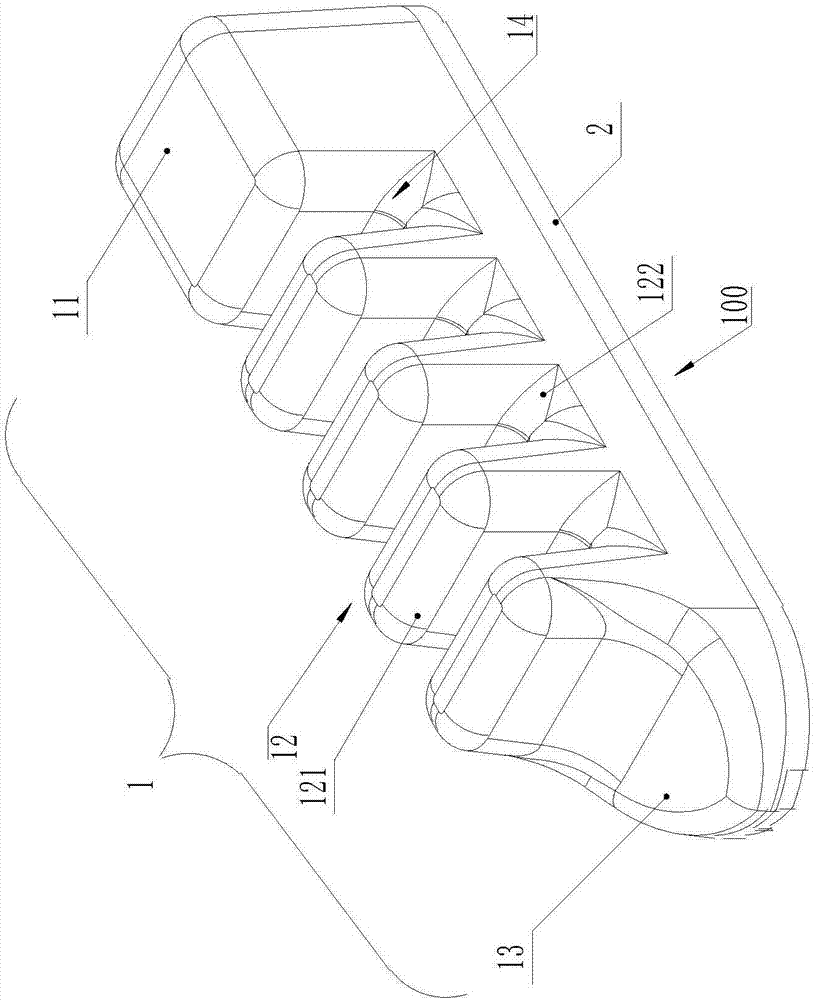

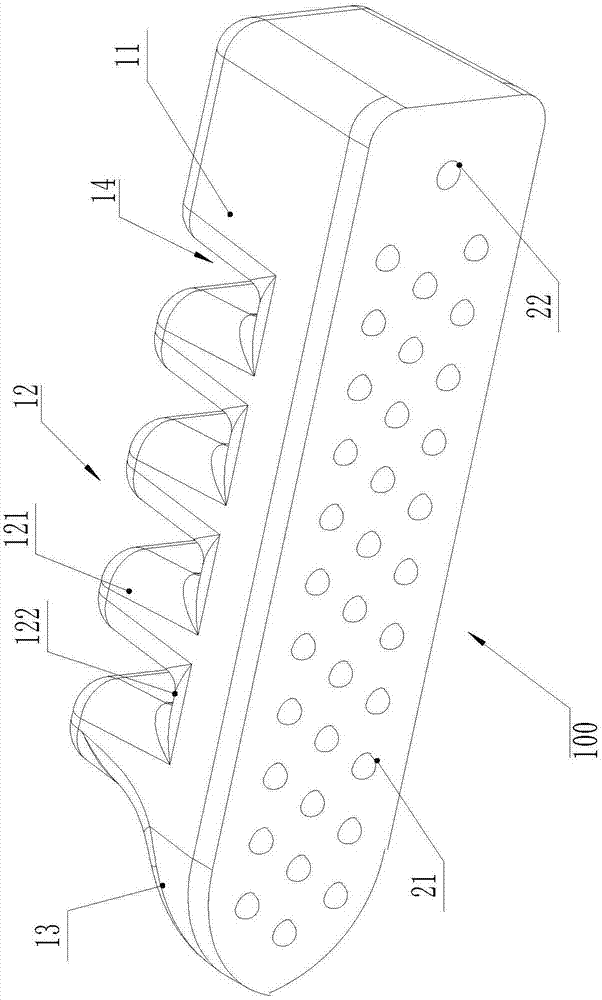

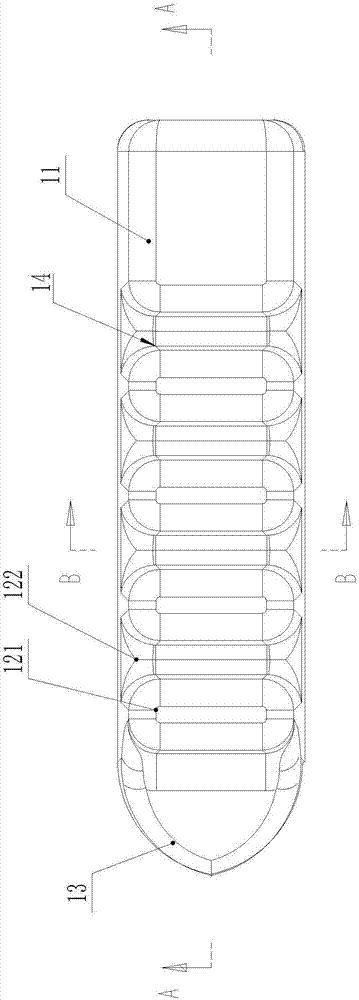

[0033] Such as Figure 1 to Figure 6 As shown, a novel flexible finger 100 includes a finger bottom plate 2 and a finger surface 1, the finger surface 1 is connected to one side of the finger bottom plate 2, and the elastic modulus of the finger bottom plate 2 is greater than that of the finger bottom plate. The modulus of elasticity of the surface 1, wherein the difference of the modulus of elasticity can be realized by using materials with different moduli of elasticity, and can also be realized by other physical methods. A material with a high elastic modulus is embedded in the finger base 2 , thereby changing the overall elastic modulus of the finger base 2 . The flexible finger 100 is generally made of elastic material or synthetic fiber material, such as rubber material.

[0034] Such as figure 1 , figure 2 , Figure 4 and Figure 6 As shown, the finger surface 1 includes a fingertip segment 13, a finger segment 12 and a heel segment 11, and the finger segment 12 i...

Embodiment 2

[0041] Such as Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the bottom of the trough 122 of the finger segment 12 is embedded with a reinforcing sheet 18 . Likewise, a reinforcing sheet 18 is embedded in the groove bottom of the transition groove 14 . The reinforcing sheet 18 is a fiber sheet, of course, the reinforcing sheet 18 and the rib sheet in Embodiment 1 can exist at the same time, so that the service life is longer.

[0042] Working principle of the present invention is: as Figure 6 As shown, the flexible finger 100 is first fixed on the mounting base 300, Figure 6 Among them, a standard air inlet and outlet joint 400 is installed on the installation base 300, and the air outlet 22 of the flexible finger 100 is set on the air inlet and outlet joint 400, and then the cover 200 is placed on the heel section 11 of the flexible finger 100, and the cover is buckled. The side wall of the cover is in the transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com