Ship engine material frame

A technology for marine engines and material racks, which is applied in the direction of assembling machines, containers of machines, containers, etc., can solve the problems of large improvement projects, large hidden dangers of driving safety, and easy shaking of columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

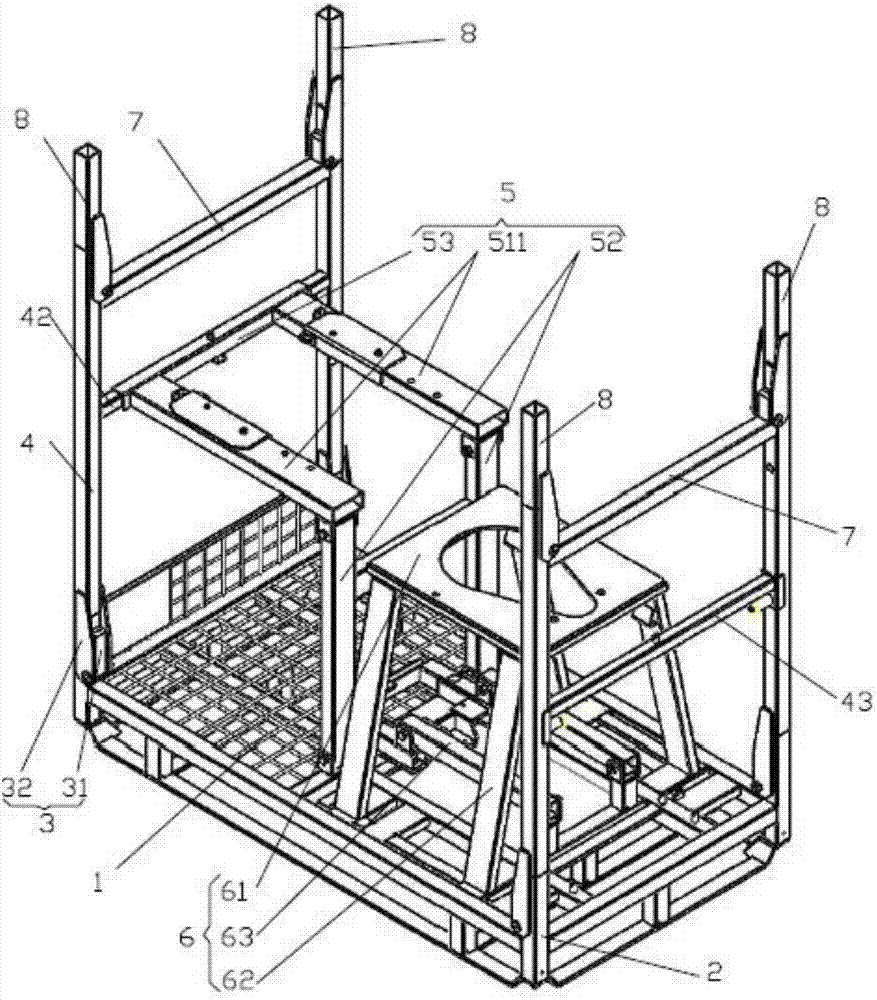

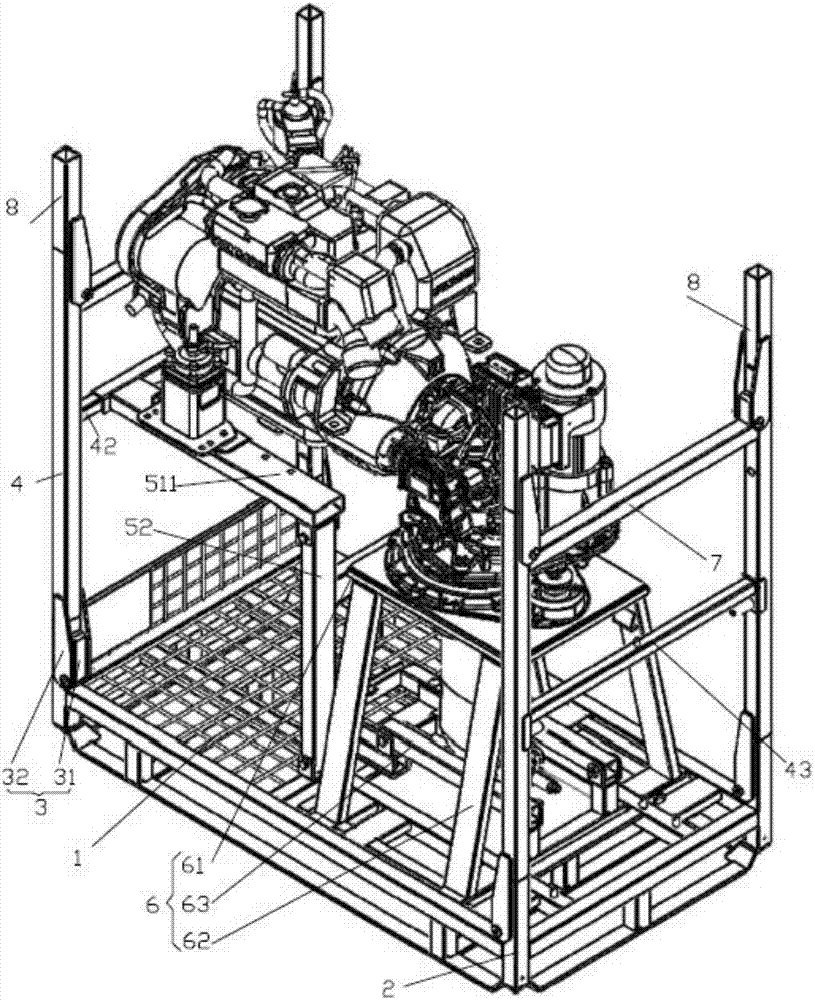

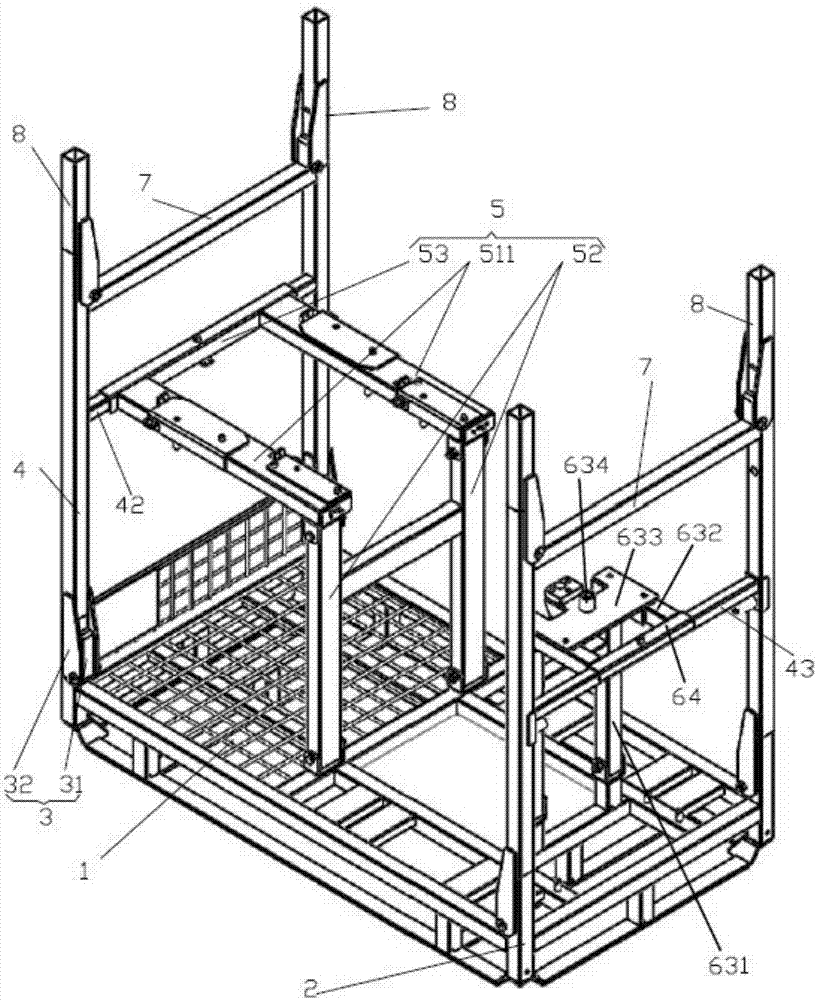

[0022] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0023] A marine engine material rack, the four corners of the bottom bracket are provided with corner posts, the top of the corner posts has a tenon, and the upper end of the corner post is rotatably connected to a movable post through a connecting mechanism; the bottom of the movable post has a tenon that matches the tenon ; There is a crossbeam between two adjacent movable columns, and a slide bar is arranged between the movable columns opposite to the crossbeam; a foldable first folding frame is arranged on the bottom support, and a second folding frame is arranged opposite to the first folding frame. frame; the first folding frame includes a mounting surface, a pillar, and a first set of rods; the mounting surface is composed of two parallel first beams, one end of the mounting surface is hinged to the pillar through a pin, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com