Carrageenan and preparation method thereof

A technology for carrageenan and boiling gum, applied in the field of carrageenan and its preparation, can solve the problems of increasing equipment maintenance costs, affecting the quality of carrageenan, and motor burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

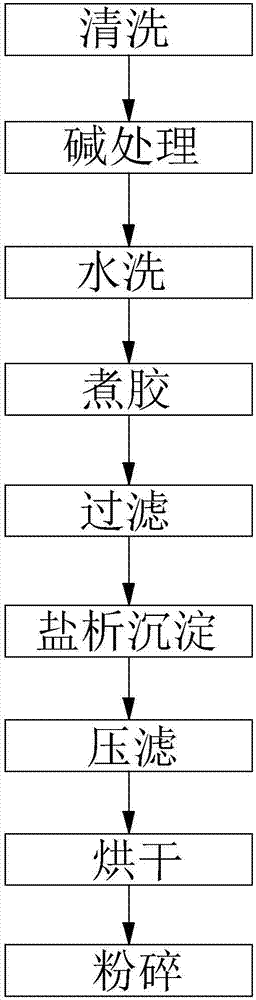

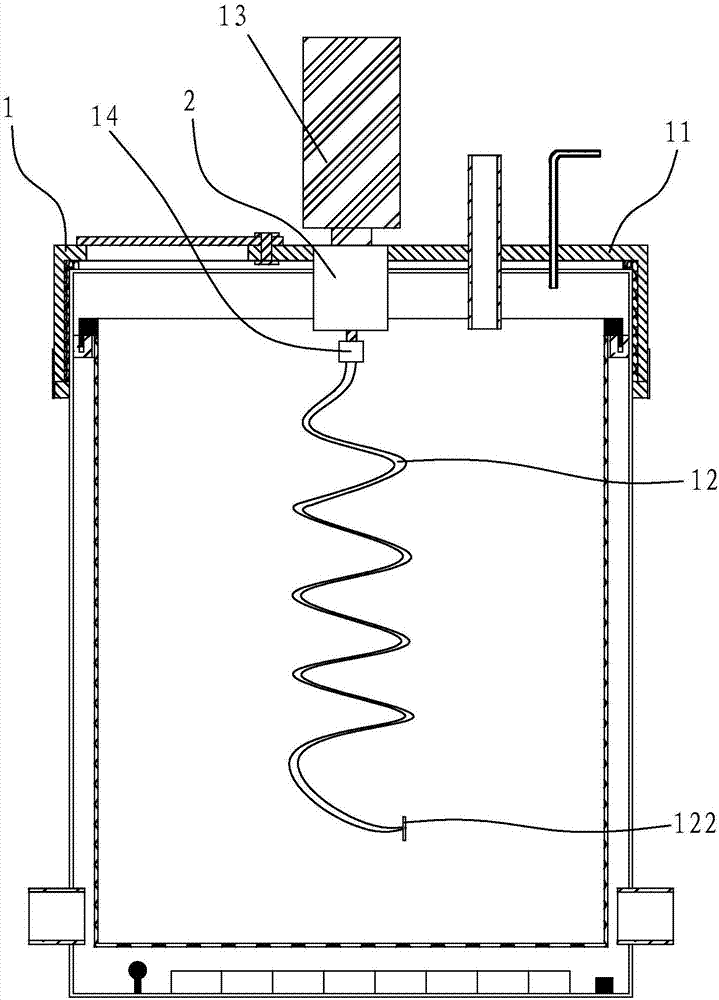

[0042] Such as figure 1 As shown, the carrageenan involved in the present invention is made of seaweed through alkali treatment, water washing, gel boiling, filtration, salting out precipitation, pressure filtration, drying and crushing. Both also include preventive steps to avoid deterioration of seaweed winding on the stirring shaft.

[0043] More preferably, the carrageenan also includes the step of adding edible ethanol during the press filtration process, the edible ethanol is selected at 85 degrees, and the weight ratio of the rubber block formed by press filtration and dehydration to edible ethanol is 1:2, and the action time is 4 hours. In this way, edible ethanol is used to further sterilize and preserve the quality, so as to improve the quality of carrageenan.

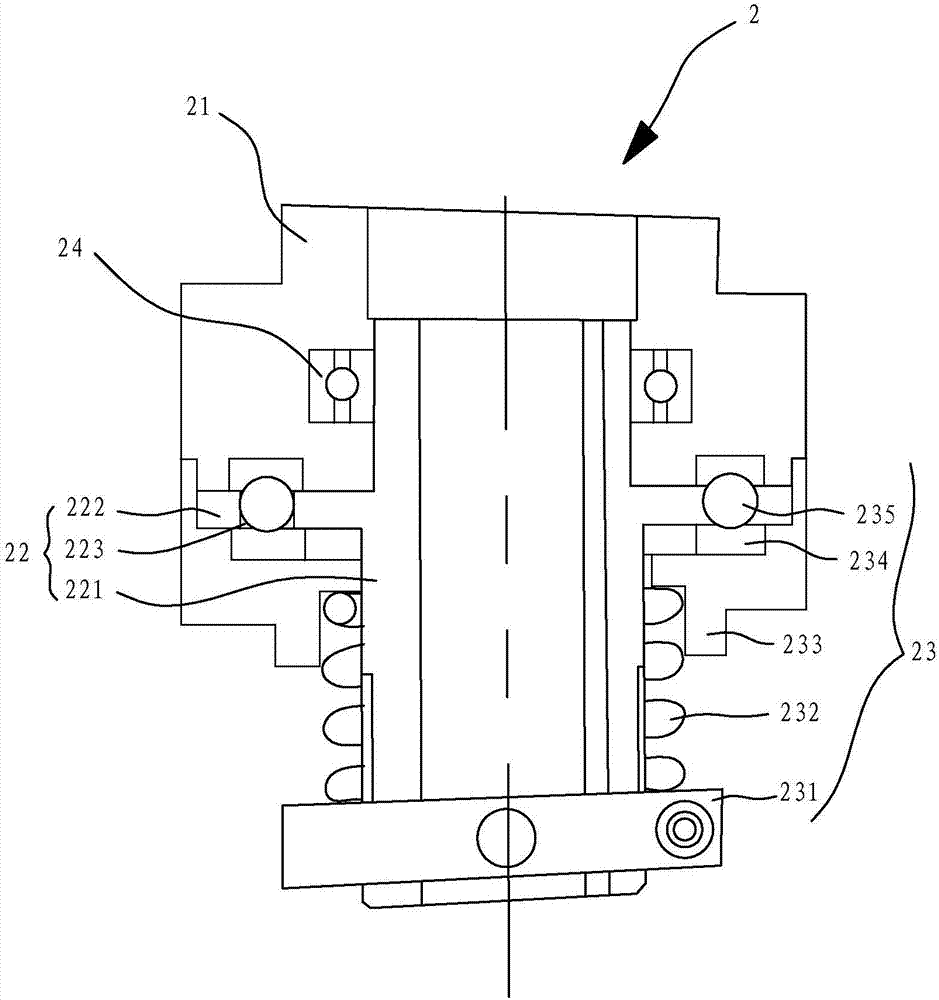

[0044] The preventive steps in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com