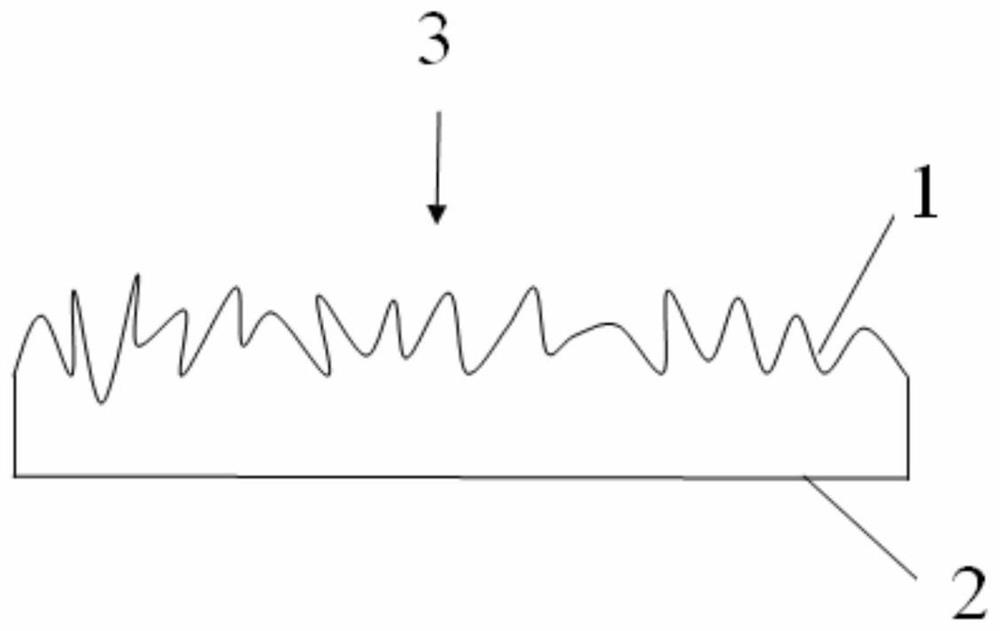

A kind of non-woven filter medium and its preparation method and application

A filter medium and melt spinning technology, applied in the field of two-component non-woven filter medium, can solve the problems of component failure, inability to meet the long-life requirements of the filter material, poor wear resistance, etc., to avoid densification. The loss of performance and air permeability is large, the filter area and the ability to hold dirt and dust are increased, and the effect of avoiding the easy slippage of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

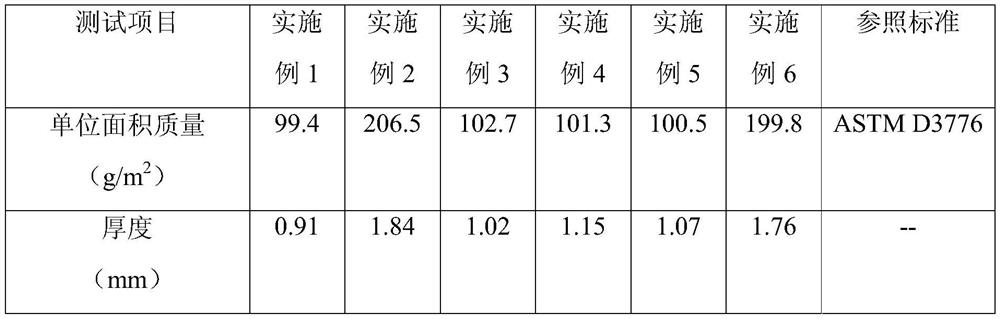

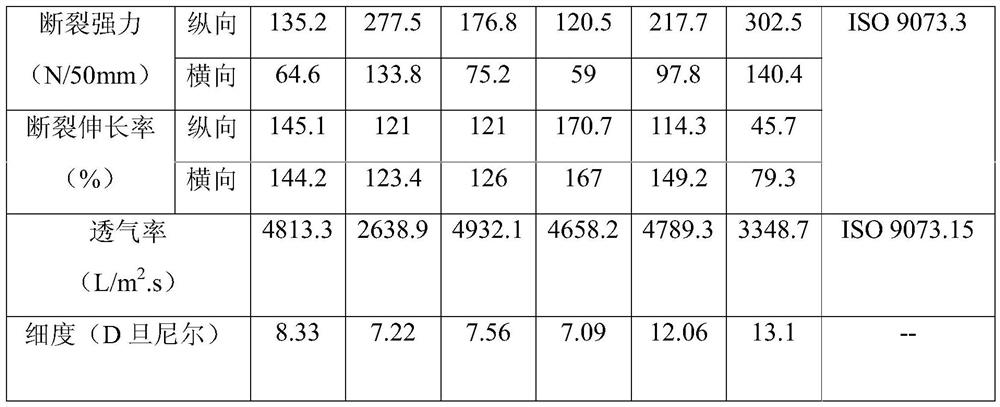

Examples

Embodiment 1

[0050] The polymer of component A is PE masterbatch, with a melting point of 130-135°C; the polymer of component B is PP masterbatch, with a melting point of 162-165°C. Component composite ratio A:B=50%:50%.

[0051] The above two kinds of polymers are olefin polymers and do not need dehydration treatment. The two polymers are melted and extruded through their respective screw extruders.

[0052] The polymer of component A is melted through a single-screw extruder. The filter is filtered, the pressure before filtration is 9.7MPa, and the pressure after filtration is 6.5MPa. Then the melt enters the metering pump for metering. The speed of the metering pump is 29rpm, and the quantitative melt enters the composite spinning box.

[0053] The polymer of component B is melted through a twin-screw extruder, and its temperature zone is set as: 210°C, 220°C, 230°C, 240°C, 240°C, 240°C, 245°C, 245°C, 245°C, 245°C, 240°C, melt temperature 237°C, component B melt is boosted by the boo...

Embodiment 2

[0056] The polymer of component A is PE masterbatch, with a melting point of 130-135°C; the polymer of component B is PP masterbatch, with a melting point of 162-165°C. Component composite ratio A:B=50%:50%.

[0057] The above two kinds of polymers are olefin polymers and do not need dehydration treatment. The two polymers are melted and extruded through their respective screw extruders.

[0058] The polymer of component A is melted through a single-screw extruder. The filter is filtered, the pressure before filtration is 9.7MPa, and the pressure after filtration is 6.5MPa. Then the melt enters the metering pump for metering. The speed of the metering pump is 29rpm, and the quantitative melt enters the composite spinning box.

[0059] The polymer of component B is melted through a twin-screw extruder, and its temperature zone is set as: 210°C, 220°C, 230°C, 240°C, 240°C, 240°C, 245°C, 245°C, 245°C, 245°C, 240°C, melt temperature 237°C, component B melt enters the filter aft...

Embodiment 3

[0062] The polymer of component A is PE masterbatch, with a melting point of 130-135°C; the polymer of component B is PP masterbatch, with a melting point of 162-165°C. Component composite ratio A:B=10%:90%.

[0063] The above two kinds of polymers are olefin polymers and do not need dehydration treatment. The two polymers are melted and extruded through their respective screw extruders.

[0064] The polymer of component A is melted through a single-screw extruder. The filter is filtered, the pressure before filtration is 9.0MPa, and the pressure after filtration is 6.5MPa. Then the melt enters the metering pump for metering. The speed of the metering pump is 30rpm, and the quantitative melt enters the composite spinning box.

[0065] The polymer of component B is melted through a twin-screw extruder, and its temperature zone is set as: 210°C, 220°C, 230°C, 240°C, 240°C, 240°C, 245°C, 245°C, 245°C, 245°C, 240°C, melt temperature 245°C, component B melt is boosted by the boo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com