Waterproof breathable novel material

A waterproof, breathable, new material technology, used in plant fibers, fiber processing, textiles and papermaking, etc., can solve problems such as slippage, poor blood circulation, and body pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Disperse and mix 52.5wt% vinyl silicone oil, 25wt% fumed silica, 15wt% vinyl MQ resin, 6wt% hydrogen-containing silicone oil, 1wt% platinum catalyst, and 0.5wt inhibitor;

[0019] Step 2: Dilute the mixture in step 1 to a solid content of 20% with n-heptane;

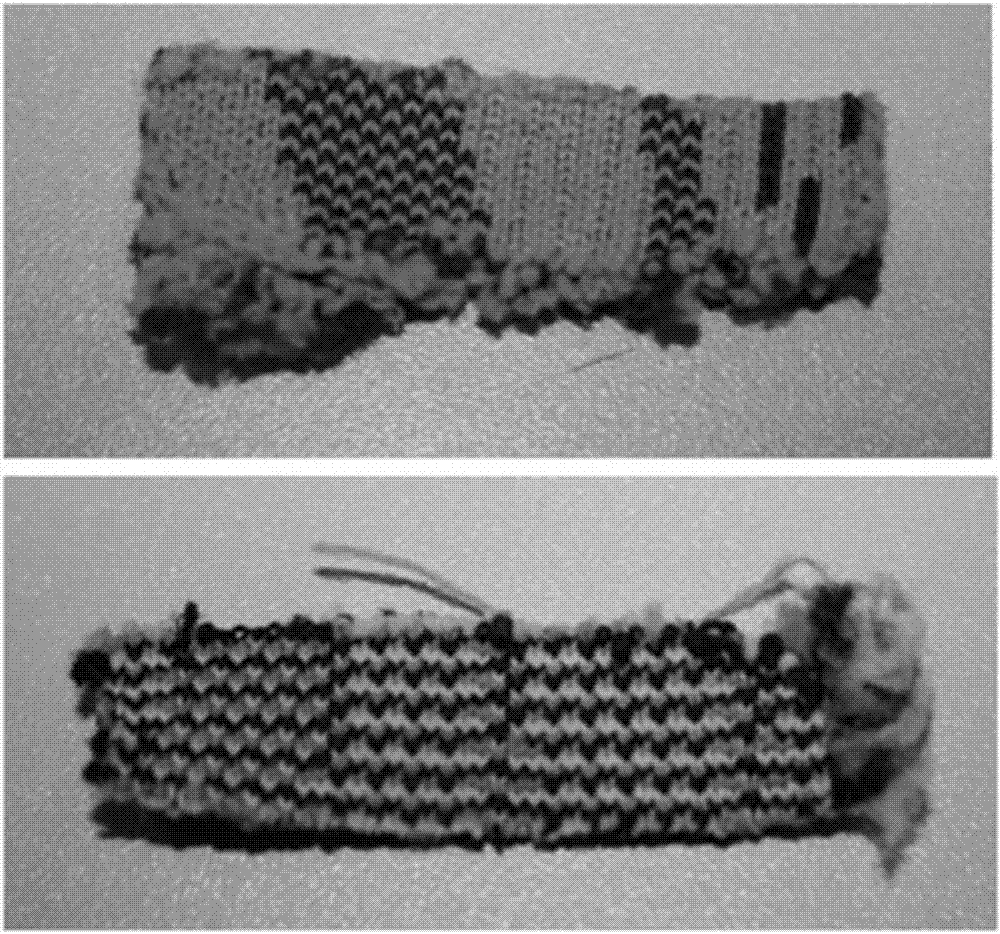

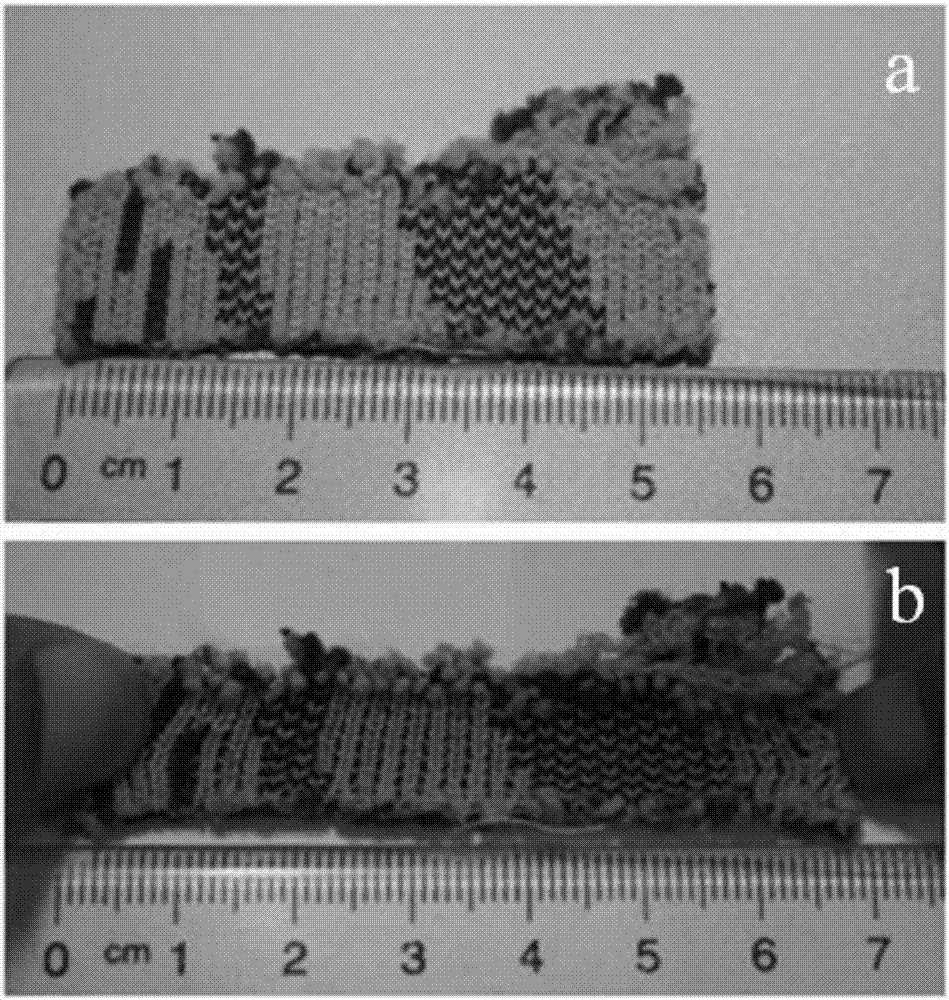

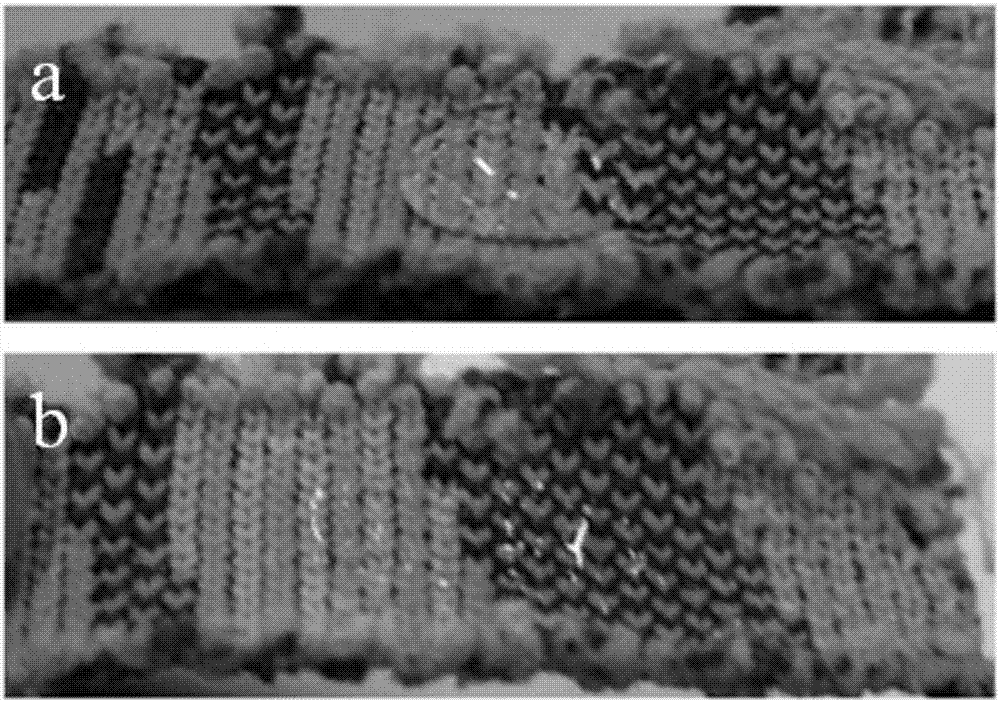

[0020] Step 3: impregnating the knitted fabric blended with polyester fiber and spandex into the liquid silica gel solution in step 2;

[0021] Step 4: Take out the soaked knitted fabric, squeeze it dry, and dry it in a hot air oven to prepare a waterproof and breathable new material sample A.

Embodiment 2

[0023] Step 1: Disperse and mix 50wt% vinyl silicone oil, 20wt% fumed silica, 23wt% vinyl MQ resin, 5.5wt% hydrogen-containing silicone oil, 1wt% platinum catalyst, and 0.5wt inhibitor;

[0024] Step 2: Dilute the mixture in step 1 to a solid content of 20% with n-heptane;

[0025] Step 3: impregnating the knitted fabric blended with pure cotton and spandex into the liquid silica gel solution in step 2;

[0026] Step 4: Take out the dipped knitted fabric, squeeze it dry, and dry it in a hot air oven to prepare the waterproof and breathable new material sample B.

Embodiment 3

[0028] Step 1: Disperse and mix 47.5wt% vinyl silicone oil, 15wt% fumed silica, 30wt% vinyl MQ resin, 6wt% hydrogen-containing silicone oil, 1wt% platinum catalyst, and 0.5wt inhibitor;

[0029] Step 2: Dilute the mixture in step 1 to a solid content of 20% with n-heptane;

[0030] Step 3: impregnating the knitted fabric blended with viscose fiber and spandex into the liquid silica gel solution in step 2;

[0031] Step 4: Take out the soaked knitted fabric, squeeze it dry, and dry it in a hot air oven to prepare a new waterproof and breathable material sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com