Rail rust removal device

A technology for rails and mounting plates, applied in the directions of rails, laying rails, rail maintenance, etc., can solve the problems affecting the smooth running of vehicles, physical injury of staff, corrosion on both sides of rails, etc., to improve work efficiency and complete rust removal. , The effect of fast rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

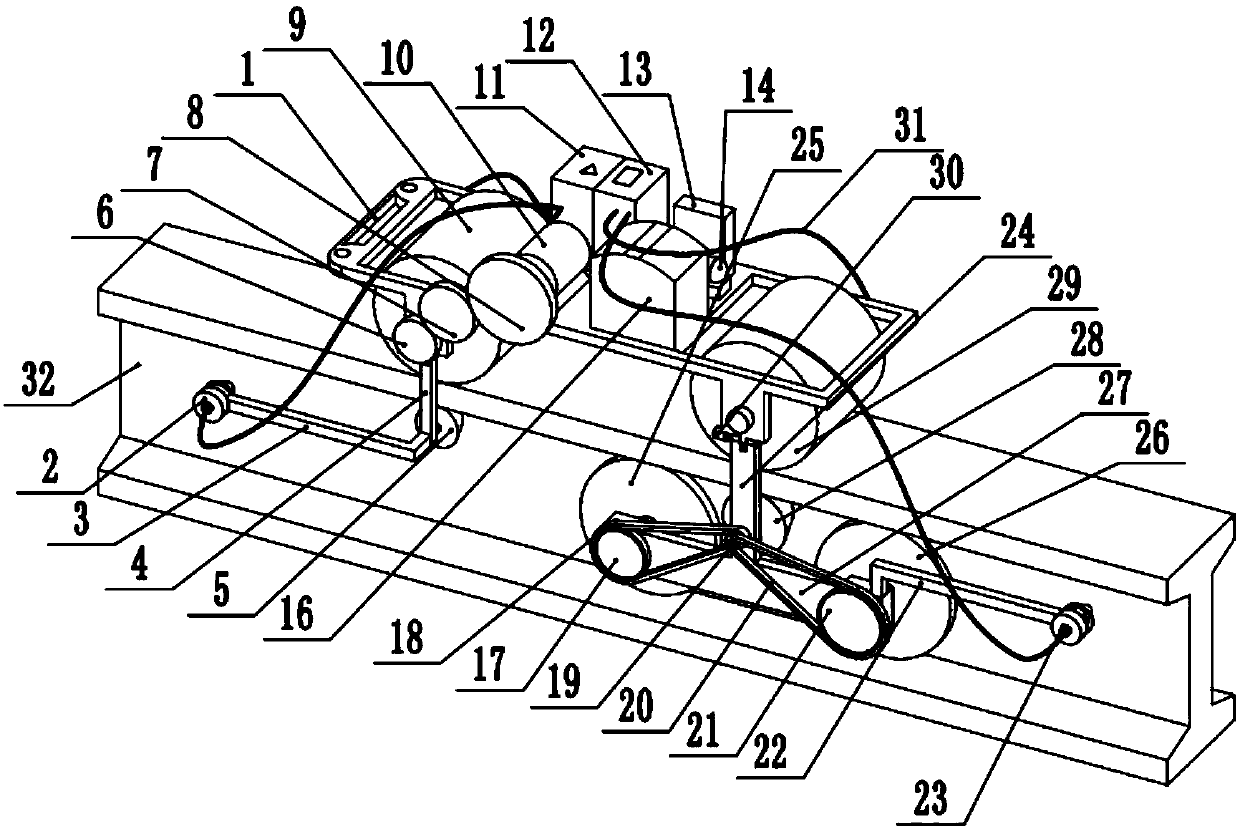

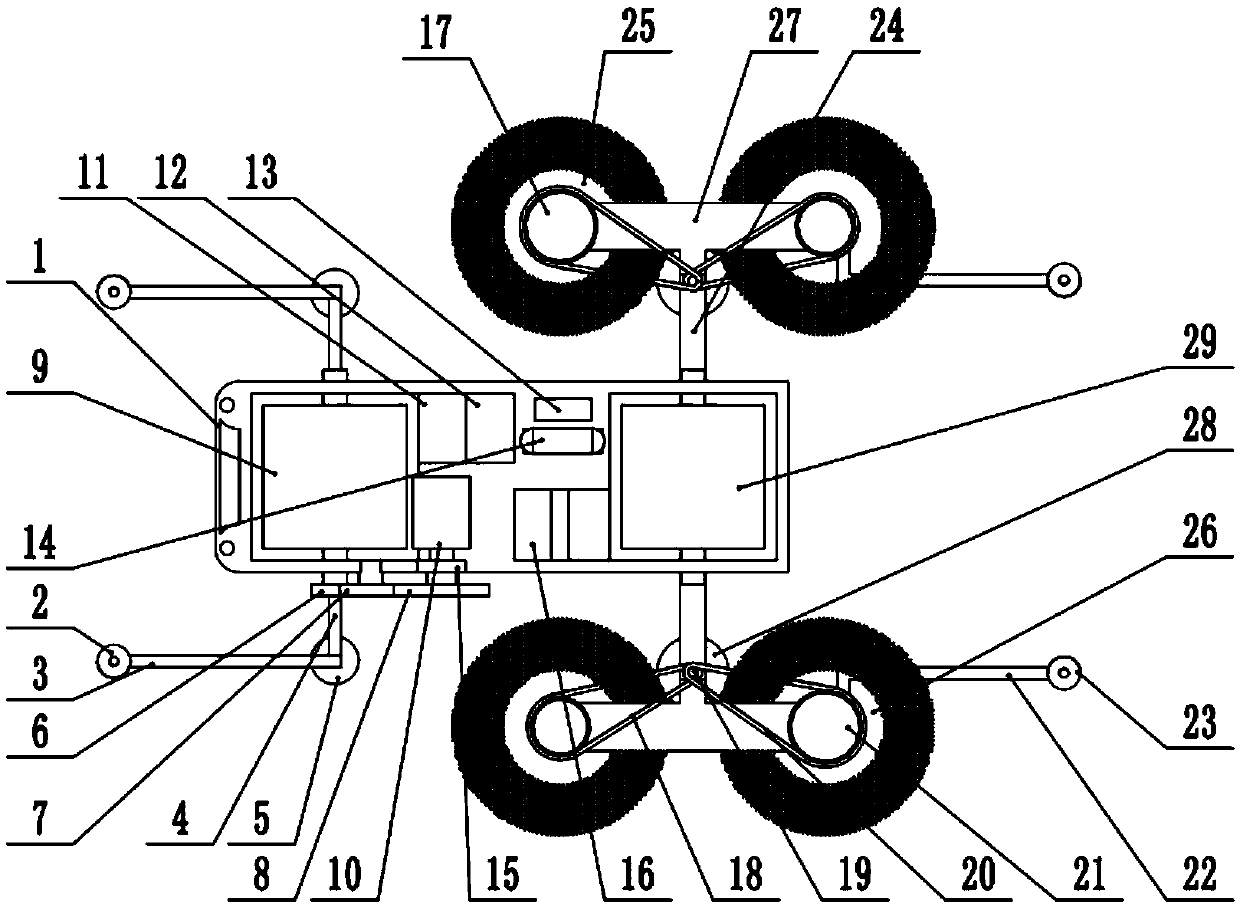

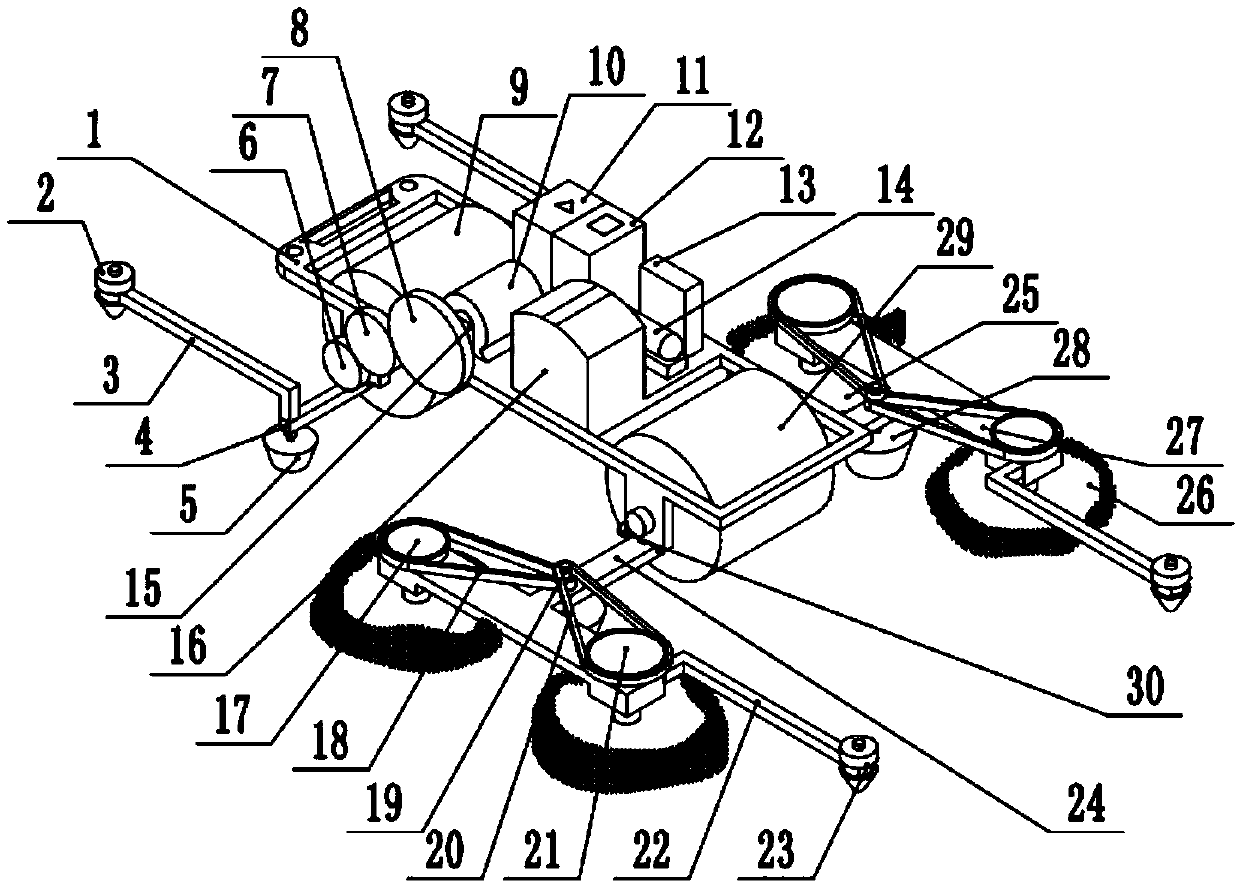

[0017]A rail derusting device is composed of a frame 1, a front nozzle 2, a front nozzle bracket 3, a front fixing frame 4, a front fixing wheel 5, a first driven gear 6, a second driven gear 7, and a third driven gear. Gear 8, front wheel 9, generator 10, derusting fluid tank 11, derusting fluid tank 12, controller 13, miniature air pump 14, reducer 15, storage battery 16, derusting brush gear 17, derusting brush chain 18, Tower gear 19, brush chain 20, brush gear 21, rear nozzle bracket 22, rear nozzle 23, rear fixed frame 24, rust removal brush 25, hair brush 26, brush fixed frame 27, rear fixed wheel 28, rear wheel 29 , a micro motor 30 and a liquid medicine tube 31, the frame 1 is structurally divided into a handle 101, a first mounting hole 102, a second mounting hole 103, a front mounting bump 104, and a rear mounting The bump 105, the front wheel mounting plate 106, the rear wheel mounting plate 107 and the main frame 108, the middle part of the front spray head 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com