Flyover structure with grooved reinforced concrete beam

A technology for reinforced concrete beams and flyover bridges, which is applied in bridges, bridge parts, bridge construction, etc., and can solve problems such as the need to expand lines, increase investment, land use, operating costs, and uninterrupted operations, so as to reduce construction difficulty and reduce construction costs. The effect of reducing and increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

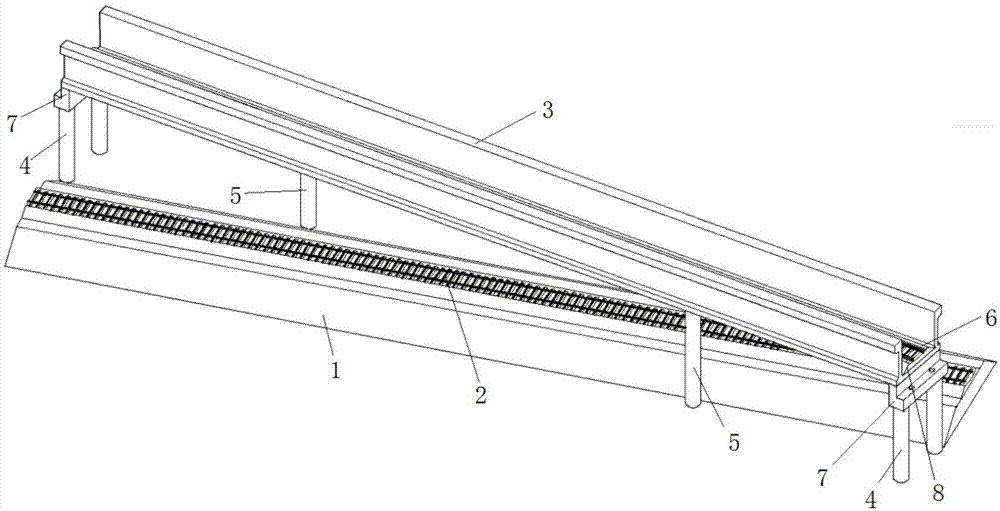

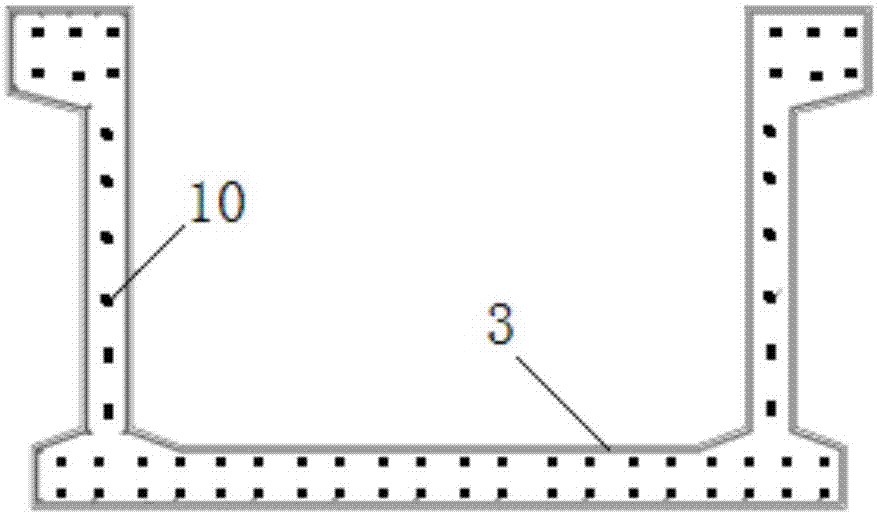

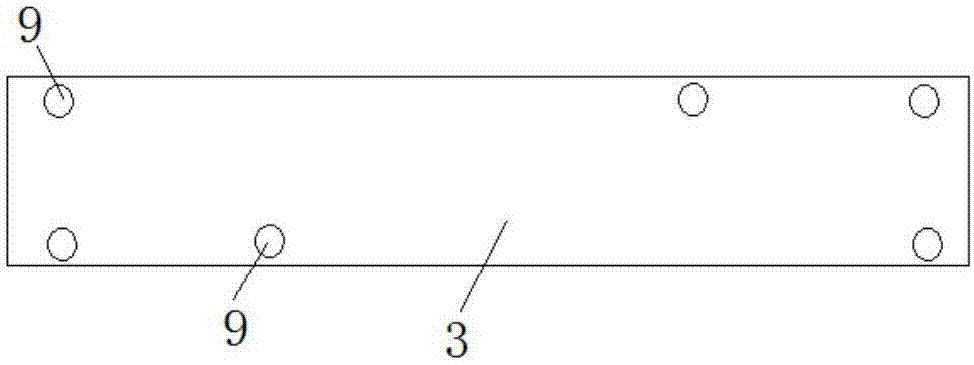

[0025] Such as Figure 1 to Figure 3 As shown, a trough-shaped reinforced concrete beam span bridge structure of the present invention includes a lower track bed 1 arranged on the ground, and the lower track bed 1 is laid with a spanned railway 2, and the ground on both sides of the lower track bed 1 Double-column piers 4 are arranged on the top, and channel beams 3 are arranged between the double-column piers 4 , and upper track bed 8 and cross-line track 6 are laid in the grooves of the channel beams 3 . The channel beam 3 is located at the upper end of the spanned railway 2, the channel beam 3 crosses the spanned railway 2 in an X shape, and the intersection angle between the centerline of the channel beam 3 and the centerline of the spanned railway 2 is less than 90°. The lower surface of the middle section of the channel beam 3 is provided with single-column pier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com