Elastic clamping mechanism for coring drilling tool

A core drilling and snapping technology, which is used in earth-moving drilling, extraction of undisturbed core devices, etc., can solve the problems of complex structure and low operation reliability, and achieve the effect of improving stability and reliability, simple structure and stable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

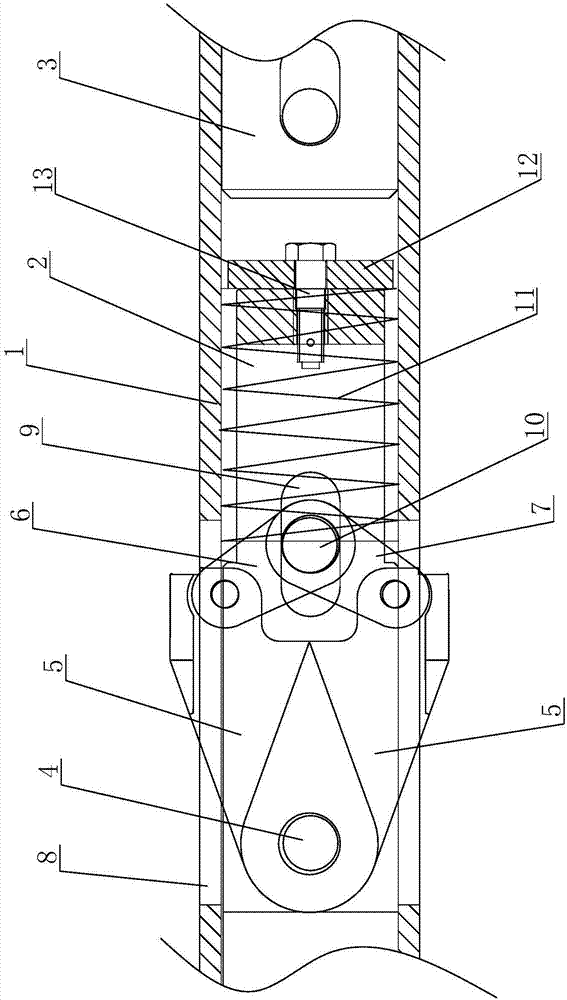

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0015] see figure 1 as shown, figure 1 It is a structural schematic diagram of an ejection mechanism for a core drilling tool provided in Embodiment 1 of the present invention.

[0016] In this embodiment, an ejection mechanism for a core drilling tool includes a recovery pipe 1 and an ejection frame 2, the ejection frame 2 is arranged in the recovery pipe 1, and the recovery pipe 1 is inside the One side of the bullet holder 2 is provided with a fishing spear assembly 3, and one end of two bullet calipers 5 is hinged on the bullet cage 2 through a first elastic pin 4, and the other ends of the two bullet jaws 5 are hinged respectively. There are a first connecting plate 6 and a second connecting plate 7, a window 8 is provided on the recovery pipe 1 in cooperation with the two bullet calipers 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com